What is Master Production Schedule?

A master production schedule is a comprehensive planning and scheduling process that clearly defines which products need to be manufactured, when to manufacture them with specific timelines, and in what quantity. MPS provides relevant information for purchasing the right amount of raw materials to minimize costly stockouts and ensure timely order fulfillment.

Although MPS sets production on the right track, it is regularly reviewed so that it matches actual customer orders, material availability and other dynamic factors. Modern-day manufacturers use advanced ERP software to plan their master production schedule. This empowers them to make automatic adjustments in their MPS in line with changing scenarios.

Further, the master production schedule enables better coordination among production, procurement and sales departments. Access to MPS allows sales teams to make realistic order delivery commitments. Likewise, purchase managers know what to purchase and when, as soon as the MPS is updated.

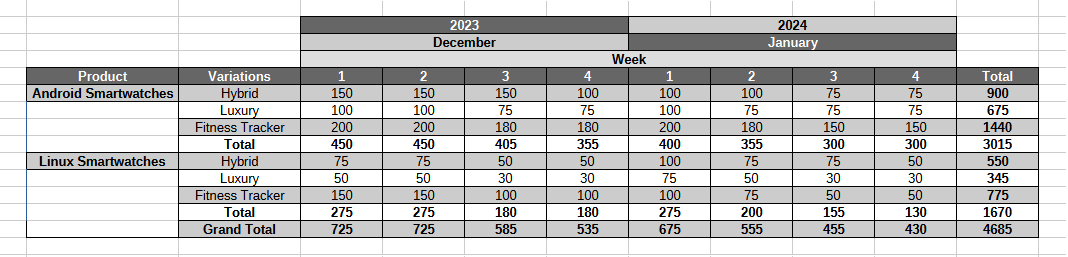

Master Production Schedule Example

Now that we’ve discussed everything from what is Master Production Schedule, its functions and components, let us move to the Master Production Schedule example.

In the below illustration, a small manufacturer sells two types of smartwatches – Android smartwatches and Linux-powered smartwatches. Both of these smartwatches can be further divided into Hybrid, Luxury, and Fitness Tracker types.

Master Production Schedule provides complete visibility into the smartwatches planned for manufacturing on the 1st, 2nd, 3rd, and 4th week of December 2023 and January 2024 respectively. As a result, the production team can efficiently plan their production process and make changes to it as per changing requirements.

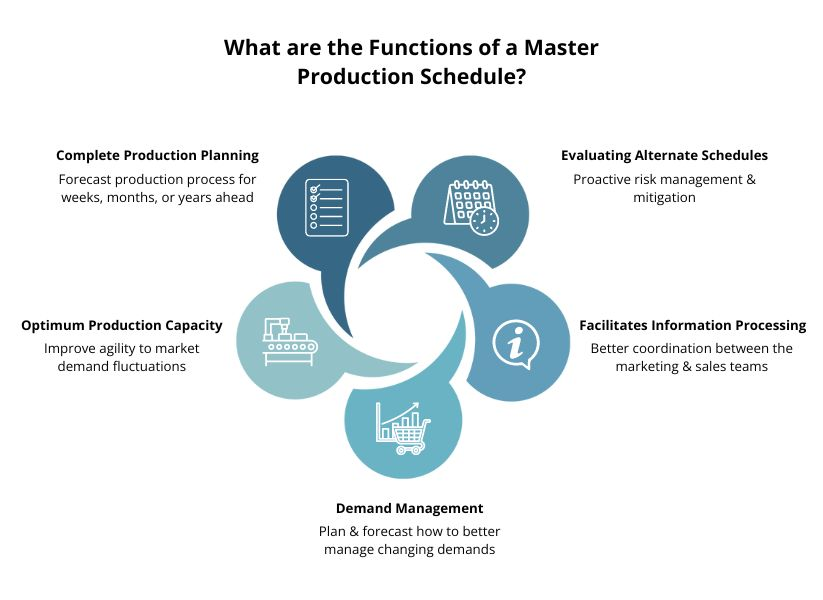

What are the Functions of a Master Production Schedule (MPS)?

Order delays often happen when wrong delivery commitments are made due to poor production schedule planning. This affects not just production but your purchase and sales teams as well. That’s exactly where a master production schedule helps. The core functions of a master production schedule are complete production planning, evaluating alternate schedules, planning production capacity, facilitating information processing, and managing demand. Let’s go through them one by one.

1. Complete Production Planning

Determine the ways to manage operations to balance labor requirements, demand, and equipment capability. So here, the Master Production Schedule (MPS) will help the business plan for the total number of products to be manufactured for a specific period.

2. Evaluating Alternate Schedules

A Master Production Schedule plan should find out ways to efficiently plan the entire production operation process and identify all the problems that are likely to occur during the process. Evaluating alternatives helps businesses proactively mitigate risks using a solid backup plan.

3. Optimum Production Capacity

Capacity planning along with a Master Production Schedule will help in cracking the requirements to meet demand, minimize costs, and maximize profits. Maintaining optimum manufacturing capacity benefits the business in a variety of ways from improved workflow, lower manufacturing cost, and better agility to demand fluctuations, to reduced need for maintaining safety stocks.

4. Facilitates Information Processing

Manufacturing ERP Software also helps in setting re-order points to make deliveries that have to be placed. It enables coordination with management information systems such as marketing, finance, etc. Master Production Schedule ensures a smooth flow of information with the marketing, sales, and finance teams.

5. Demand Management

Master Production Schedule facilitates better demand forecasting, strategy building, and bridging the gap between the company’s internal operations. Businesses can calculate the elasticity of demand to measure the responsiveness of the demand to changes in pricing. However, it is also important to ensure that the Master Production Schedule is provided with the most up-to-date information.

Components of a Master Production Schedule

You can only form a production schedule once you have complete details about its components. The main components of MPS are product list, product variant list, production timeline and product quantity. Let’s take a look at each of them.

1. Products List

Products List is an important component of the Master Production Schedule (MPS). It contains a complete catalog of all the stock keeping unit (SKU) planned for manufacturing. It is up to the manufacturer to keep certain products at the top of this list. While some manufacturers may choose to keep high-priority products, others may keep widely popular products at the top of the list.

2. Product Variants List

Another crucial component of the Master Production Schedule is product variants. It is also commonly referred to as a Sub-list of the original Products List. Product Variants splits items in the original product list by size, color, ingredients, and other parameters. For example, a company selling smartwatches will create a Product Variants List consisting of different smartwatches split by their usage type, hardware configurations, colors, and price range.

3. Time Factor

Time Factor is another important component that helps manufacturers develop a realistic production plan and meet the forecasted demand for the product in the next week, month, or year. Sometimes, things do not happen as anticipated. A good production plan should be flexible enough to make emergency adjustments to accommodate the changing needs.

4. Quantities to Manufacture

This component denotes the number of product quantities the manufacturer has planned to manufacture in the upcoming week, month, or year. Product quantities are not a single digit of number. Instead, the manufacturer assigns it to different variations of products. For example, manufacture 500 units of red color plastic bags, and 200 units of black color plastic bags.

Different Master Production Scheduling Techniques

The three commonly used production techniques are Make to Stock, Make to Order and Assemble to Order. As a manufacturer, you have to make sure that your master production schedule aligns with the production technique you follow. Some manufacturers have to follow both the push and pull strategy. In such cases, the ERP system is flexible enough to adjust MPS to handle both strategies.

1. Make to Stock (MTS)

Manufacturers that use MTS technique rely on demand forecasting to produce goods in advance and stock them for faster order fulfillment. Here, MPS is used to plan the production schedule for finished goods. This avoids finished goods shortage, and the purchase team can form long-term contracts with suppliers to secure raw materials.

2. Make to Order (MTO)

In MTO, the production is scheduled only after the customer order is received. That means you can’t have finished goods ready. In this case, MPS is used to ensure that critical raw materials, especially those with long lead times, are scheduled in advance. So you can immediately start production when the order comes.

3. Assemble to Order (ATO)

Assemble to order is a production technique where components and sub-assemblies are stocked before the customer order arrives. Therefore, the MPS schedule focuses on producing standard components and sub-assemblies, which can be immediately deployed for final assembly based on actual customer order specifications.

| Production Technique | What MPS Schedules |

|---|---|

| Make to Stock | Finished Goods |

| Make to Order | Raw Materials |

| Assemble to Order | Components and Sub-assemblies |

What are the Benefits of Master Production Planning?

Why are an increasing number of companies across the world adopting Master Production Planning? Here are the key benefits it offers:

1. Increased Production Capacity

Production planning is a broader concept that encompasses different activities such as production capacity planning, resource allocation, and pre-planned procurement of raw materials with procurement software. One of the key benefits of implementing a Master Production Schedule is that it helps decision-makers develop strategies to achieve their production goals.

2. Higher Asset Turnover Ratio

Asset Turnover Ratio depicts how efficiently a company is using its assets to generate revenue. The higher the Asset Turnover Ratio, the better it is. The asset management module in the Master Production Schedule helps companies calculate the percentage Asset Turnover Ratio and improve it by making the best of their resources.

3. Lower Inventory Costs

Another benefit of the inventory management system module in the Master Production Schedule is that it helps businesses align their production to meet the constantly changing market requirements. By adopting a balanced and cost-efficient way, companies maintain adequate cash flow, minimize excessive inventory storage costs, and reduce out-of-stock incidents.

4. Reduced Machine Idle Time

Master Production Planning promotes better material management, and improves visibility into different aspects of the production process — raw materials management, customer demands, and machine capacity data. It helps optimize the production resources to their maximum capacity and reduce idle time. Reduced idle time pays off with reduced energy consumption and cost savings.

5. Timely Order Fulfilment

Business Management Software brings complete visibility into the production process. With deeper insights into the entire process, the company can reject orders that cannot be met in the anticipated time frame. Overall, it helps stress out the manufacturing department and ensures orderly fulfillment of the products while maintaining acceptable quality level for maximum customer satisfaction.

Transforming Master Production Planning with Innovation & Technology

Traditionally, businesses used spreadsheets for production planning and scheduling. Over-dependence on spreadsheets led to various issues. It increased data entry and led to efficiency loss. Besides, human errors could lead to inadequate or surplus manufacturing, thereby causing poor customer experience, loss of opportunities, and increased production costs.

Adopting the Enterprise Resource Planning (ERP) tool helped manufacturers overcome these traditional challenges. ERP consolidates data from different departments and supports aggregate planning to quickly scale up production to meet market trends.

Summing Up…

ERP Software provides a complete set of modules that automate the production process, reduce human errors, and minimize defects. It facilitates better coordination between different departments and provides analytical tools for production planning & cost control measures.

Sage X3 is a strategic tool that enables manufacturers to use its proactive framework to employ various high-level strategies in the production process. They can align the manufacturing process to changing market conditions, and take advantage of modern technology to achieve manufacturing excellence.

Master Production Schedule FAQs

1. What is the Definition of Master Production Schedule?

Master Production Schedule meaning is that it is a comprehensive report that records the timing & quantities of the production activity, in order to prevent unexpected mishaps in the production process and allocate the required resources.

2. Which Information is Stored in a Master Production Schedule?

Master Production Schedule contains a host of information such as different product types scheduled for production, the number of quantities scheduled to be produced every week/ month/ year, the actual date of production, materials/ ingredients required, and so on. However, the actual information may depend on the manufacturer and the complexity of the product.

3. Which Tool is Useful for Generating a Master Production Schedule?

The best ERP software in India provides demand forecasting, production planning & scheduling, inventory management, and other powerful capabilities required to develop a Master Production Schedule. Decision-makers get access to real-time reports, analytical tools, and customized dashboards to increase the responsiveness to the customer’s demands.

4. How Do KPIs Benefit the Master Production Planning Process?

A Key Performance Indicator (KPI) is a quantifiable measure of performance during a certain period. KPIs benefit the Master Production Schedule process through the following ways:

- Production Volume: This KPI is used to measure the production volume in quantities.

- Cycle Time: This KPI is tracked using PLM software to determine the time required to complete a production cycle.

- Inventory Turnover: This KPI is used to determine how frequently a stock is replaced.

- Defect Rate: Indicates the percentage of defective products out of the total production

5. How is Master Production Schedule Different from the Production Schedule?

Master Production Schedule is a high-level plan for the overall manufacturing activity in the medium to long-term horizon, such as determining which products and variants to produce and in how much quantity. In contrast, the Production Schedule provides thorough details about each production activity such as the steps that are needed to be executed, resources needed to be allocated, and the timing of each job.

6. Why Business Needs A Master Production Schedule?

Master production schedule makes sure that your production is running on time, aligned with forecasted demand and actual customer orders. If you need to set order priorities, MPS lets you do that. Besides, it helps you optimize inventory levels and efficiently use resources such as machinery and labor.