Technology is changing as the world changes. So adapting to the latest technology is necessary to stay updated and competitive. Even in the field of business, technology is evolving rapidly. A study says that 82% of the company that switched to the cloud saved a large amount of money, and there is a tremendous improvement in the workflow.

Enterprise resource planning software (ERP) is the most significant innovation for the business to function efficiently. It is an intelligent solution to manage and control the entire company’s business functions.

What is Manufacturing ERP Software Solution?

A Manufacturing ERP system has a centralized database that unifies all the business processes like finance and accounting, purchasing, supply chain, and materials requirement planning(MRP) functionality, including bill of materials(BOM), master planning, and product scheduling. It tracks raw materials, work in progress and finished products inventory by item.

Manufacturing ERP integrates with functions like payroll, customer relationship management (CRM), warehouse management, product lifecycle management (PLM), project management, e-commerce, and third-party add-on apps.

Hence a manufacturing ERP solution is made exclusively for manufacturing businesses or companies as part of the all-industry solution offering MRP modules and inventory management.

Nowadays, manufacturing ERP systems are cloud-based solutions with business intelligence and smart shop floor IoT sensors, AI and ML features controlling and monitoring manufacturing processes and providing alerts.

Functions of the Manufacturing ERP

ERP serves as a natural fit for the manufacturing industry. In the manufacturing sector, several business processes must be kept running daily to keep a company running. An ERP system can streamline all these business processes listed below.

Inventory management: ERP aids in inventory tracking, data analysis and replenished strategy.

Supply chain: In this process, ERP software provides real-time information and organizes the entire process. Draw data from an internal and external sources to assist effective supply chain planning and management. Tracking vendor performance is possible.

Maintenance: With an ERP system, it is easier to schedule, ticket and manage work orders while enabling robust data tracking and analytics to improve Maintainance effectively.

Equipment performance tracking: ERP can track the equipment performance data from sensors and reports. It helps in enabling more informed, proactive and targeted Maintainance.

Quality assurance: ERP easily helps track QA results. It creates vast data stores that help in identifying maintenance requirements.

Purchasing: Visibility in all areas of operation. Purchase and requisition can be organized easily.

HR: ERP is for manufacturing and operations, apart from that, it can also be applied to HR functions like performance reviews, goal tracking and many other HR functions.

Also read: Top 9 Ways Cloud ERP Can Benefit Furniture Manufacturing

Benefits of implementing Manufacturing ERP

There are vast benefits to implementing manufacturing ERP for any industry. Let’s explore some of the benefits.

Clarity of data in the business processes

ERP is a centralized system with a single database. All the data of various business processes are stored in this system. Any authorized user can access the data from anywhere and from any device. It enhances communication, collaboration and coordination across the departments.

Centralized data collection and analysis

The major function of the ERP system is to collect, analyze and store data in silos. Any user can easily access the data. Data analysis is crucial for the company, as it helps in driving insightful decisions regarding maintenance, machine usage, procurement, supply chain and more.

Increased efficiency in business processes

Data visibility and clarity increase the efficiency of business processes. When the entire process is optimized and streamlined, it will increase productivity and boosts profit.

Minimize operational costs

When the business’s everyday operations are streamlined and organized, it will be easy to identify areas where money is wasted unnecessarily.

What is the difference between standard ERP and manufacturing ERP?

There are two types of ERP systems, standard ERP and manufacturing ERP.

You can get all the features common to all businesses in standard ERP. It sticks to the principle that one size fits all. But it needs full manufacturing integration and key functionalities for a manufacturing industry-specific business. So lack of integration between ERP functions and industry requirements can restrict data views.

Whereas manufacturing ERP is specifically designed for the manufacturing industry. It provides advanced functionality for industry-specific requirements. It can easily integrate with core business processes by providing complete visibility and control of the manufacturing company.

Signs a manufacturing company is ready for an ERP system

Manufacturing ERP is solely intended to manage manufacturing processes. Here are some reasons you should consider if your manufacturing management is lagging.

- Check if your existing systems are failing to manage operations.

- Failing to support the growth of the company.

- Lacking security requirements to mitigate tasks.

First, it is essential to identify the broken system and decide to invest in an ERP system.

Which ERP is best for manufacturing processes?

There are different types of ERP for deployment, the three common types are listed below.

On-premise ERP system

An on-premise ERP system offers software control after it is implemented in the company. The ownership included the hardware and software. It also involves the risk and management of the system.

Cloud ERP system

It is a cost-effective solution that provides continual support, updates, training and flexible customization from an ERP provider. It is a comprehensive, flexible and modular system for all businesses.

Hybrid ERP system

In this type, deployment can be the hosting of cloud-based ERP and on-premise ERP systems. It provides the users to have the liberty to migrate between different delivery models.

What is cloud manufacturing ERP?

Cloud manufacturing software helps companies to streamline all the production processes from creation to distribution. The most significant advantage of the cloud system is that the employee can access the data of all processes anytime and anywhere from any device. A desktop is not mandatory for a cloud ERP system.

Cloud ERP system is a comprehensible, affordable and modern solution for all businesses. It is a reliable solution for dealing with today’s digital economy.

Most importantly, cloud vendors provide mobile access to the employees on the production floor, so they can easily access any information with an internet connection.

A cloud-based solution is well suited for a company whose employees work remotely or if the company is highly mobile. In contrast, if employees are tied to desktop systems, on-premise ERP is recommended.

Key features of cloud Manufacturing ERP

Cloud-ERP is a package of industry-rich features. So if you are looking for a cloud ERP system, here are some of the features enumerated below.

Product management

This significant feature provides visibility of the product lifecycle. It includes the monitoring of work-in-progress goods. Plus, visualization of how labour forces are allocated, quality assurance and some vendors include CAD.

Supply chain management

Cloud ERP for supply chain management controls the entire process from supplier to supplier. Some of the features of this process are demand forecasting, finished product inspection and management of raw materials. Some cloud manufacturing provides the customer to configure a product online.

Accounting for manufacturing

Financial and accounting tools are a significant part of cloud ERP software. Accounting functions may include basic accounts, accounts payable and accounts receivable. Vendors also provide advanced accounting features like budgeting, forecasting and tax calculation. From vendor to vendor, the features may vary.

Transportation and logistics

Cloud ERP vendors provide real-time tracking of the product as it is distributed to the customer. Other rich features include inventory forecasting, diagnostics and route mapping. Vendors also offer tools to predict and order raw materials based on product demand in the market.

Asset Management

Fixed asset management is crucial for the company. It is commonly available in the cloud ERP system to keep track of assets such as buildings and equipment. In this, the features include record Maintainance, tax information and tracking of energy costs linked to these assets.

Industries that benefit most from cloud ERP

Cloud manufacturing ERP is preferred by many businesses, with manufacturing as the major process. Below are some sectors where companies use it as a comprehensive tool.

- Pharma industry

- Furniture industry

- Retail

- Distribution

- Food and beverage industry

- Aerospace

- Chemical industry

Conclusion

Cloud ERP is a faster, more flexible and reliant solution for all types of business. A cloud ERP has a robust database to connect and align your business. To choose efficient manufacturing for your company. Select a vendor with in-depth knowledge of providing the right ERP for your business. If you are customizing features for your manufacturing business, the vendor can easily suggest accurate features for your business.

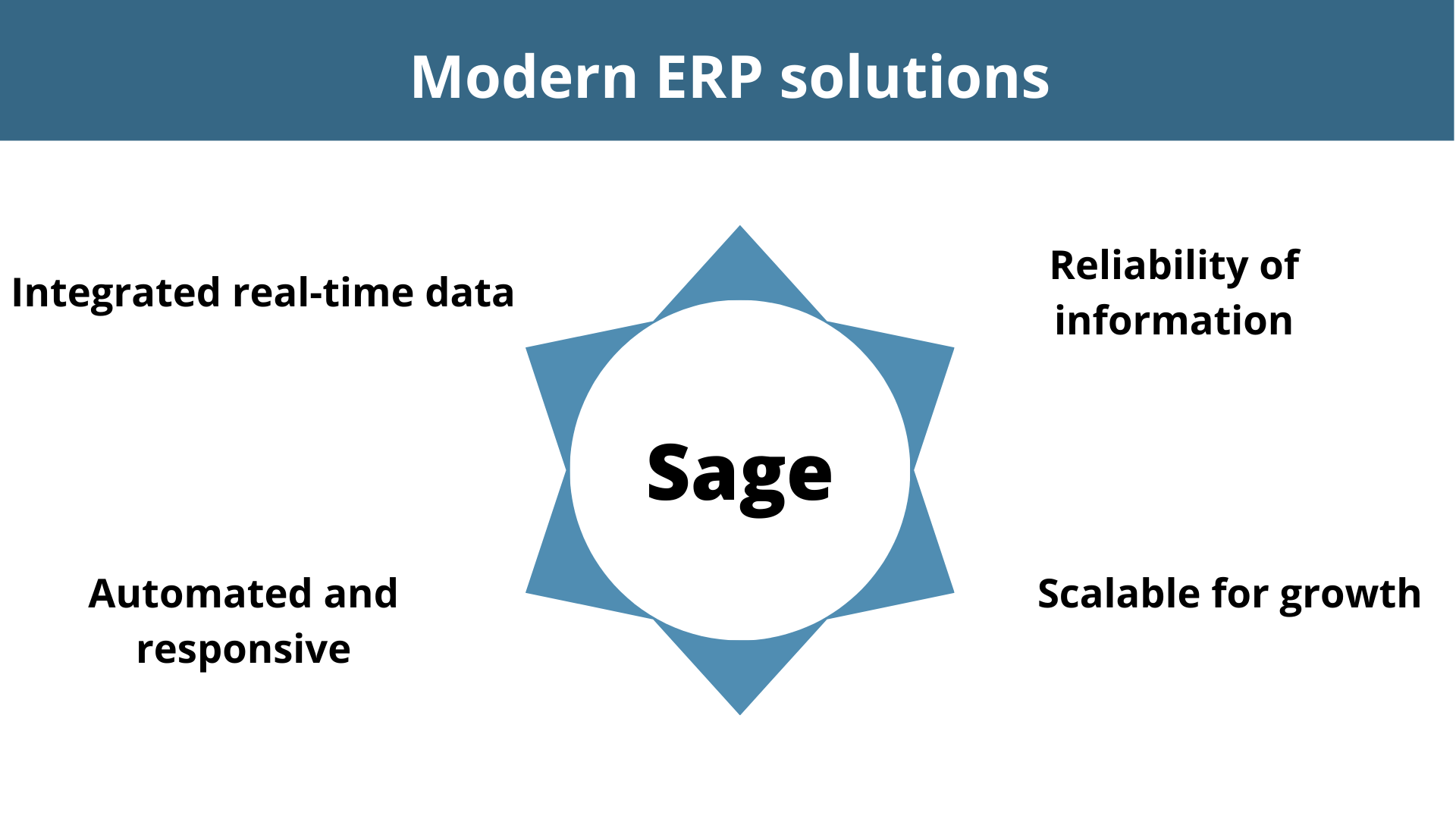

Sage Software Solutions is a leading IT company with an array of advanced ERP Software solutions. Our proprietary products — Sage X3 and Sage 300 will help you cut your operational expenses, improve business productivity, increase operational efficiency, forge robust customer relationships, and strengthen association with vendors, suppliers, and distributors. So, if you are looking to reinforce your business fundamentals and emerge as an industry leader, then please schedule a call with one of our sales representatives.