The quality of the product is pivotal for any business. Especially in the healthcare business, the quality of each product is crucial as it involves the lives of people. And failing to meet its requirements will have a negative impact on companies reputation. In the very recent past, we saw how the government revoked the licenses of 18 pharma companies over poor quality issues.

Quality, consistency and safety are the top priorities in the pharmaceutical sector. And being compliant is mandatory or the licenses of the company will be in jeopardy. Therefore it’s of utmost importance to have a definitive Quality Control Plan in place and for that, you need to have good software in place to manage the quality control process.

The pharmaceutical sector is highly regulated. Companies that implemented the latest technology were able to successfully maintain the quality standards. Automation of business processes is the key to successfully adhering to compliance and fulfilling quality requirements.

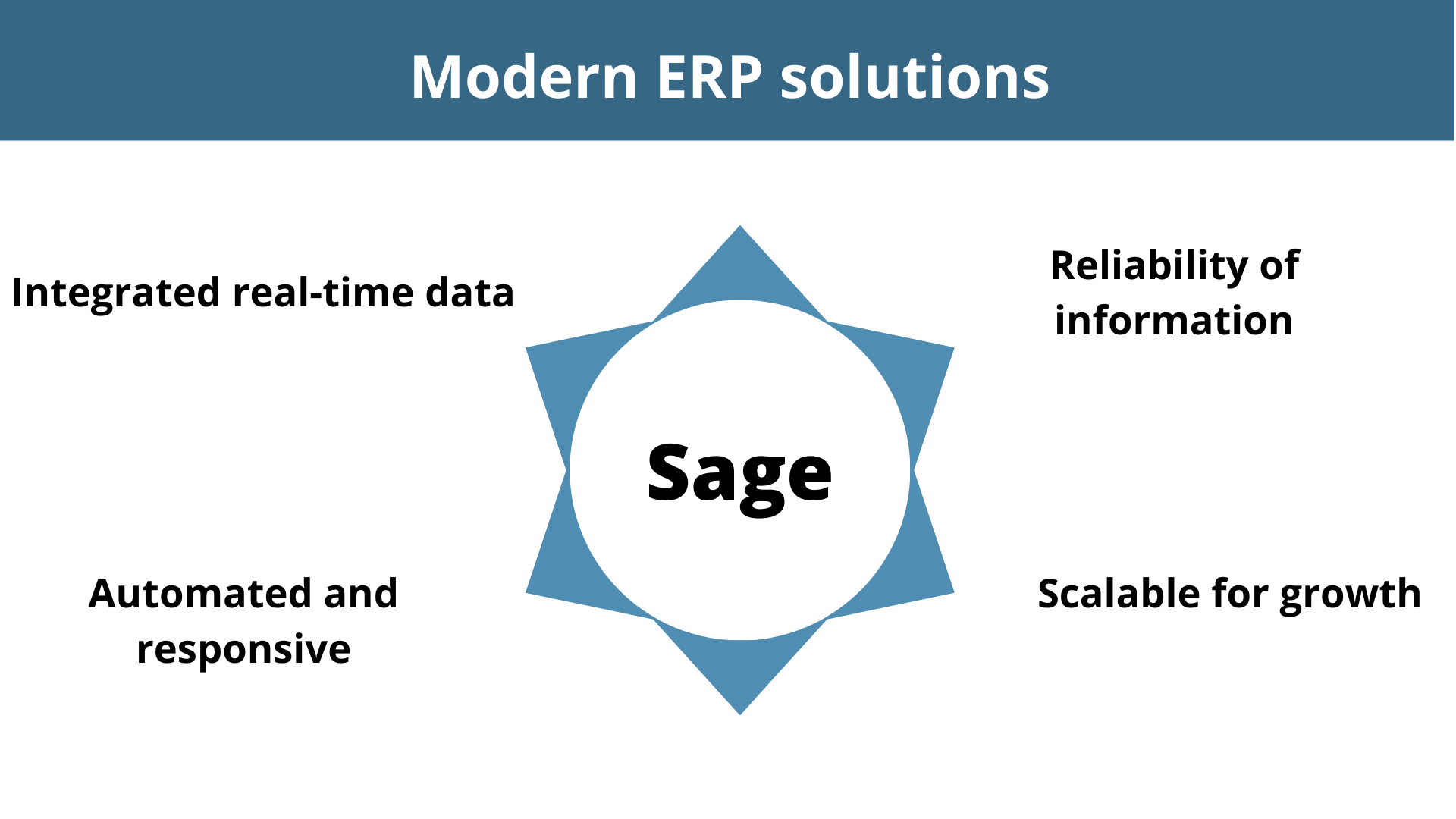

Technologies like ERP system will have quality management and control functionality. Plus, it will have all the features to encompass from the sourcing of raw materials, manufacturing stage and post-manufacturing stage.

Quality Control – The keystone of the pharmaceutical business

Quality has a lot of significance in the pharmaceutical sector. It is obligatory for them to meet local and international compliance. Quality standards must be maintained to ensure that the goods manufactured are safe for human consumption.

For example, to ensure high-quality products, the quality of the raw materials must be assessed such as if the materials are meeting specific standards. Next, inspect the condition of the machinery and the equipment used for the manufacturing process.

And focus should be laid on the manufacturing environment. It should be considered who should supervise the entire manufacturing process. A good ERP system can assist in designing systematic workflow processes and managing protocols better.

So, if an error occurs in any of the above operations, it will impact the quality and will incur a loss, additional costs etc. Each process of manufacturing process should be handled meticulously to produce good quality products.

Also Read : What is the difference between Quality Control and Quality Assurance?

What does a quality control department do in the pharmaceutical sector?

Quality control has the following responsibilities to oversee in the pharmaceutical industry.

- Managing all the quality control tests.

- Allocation and configuration of all the testing equipment.

- Managing all the quality control specialists and their tasks.

- Setting up the right testing procedures.

- Maintaining proper records and documentation.

- All the results must be recorded accurately.

Apart from these, they should analyze the market trends and demands. Plus, they must run stability tests on batches promptly. Pharma companies should also monitor changing norms, analyze administrative requirements, and understand the evolving market trends.

So taking all these factors into consideration, the pharmaceutical sector should be able to streamline and optimize business operations efficiently to produce high-quality goods at affordable rates.

Ways to improve quality control in the Pharmaceutical Industry

Quality control can be improved by integrating operational excellence with data-driven insights. This will improve the productivity of quality control departments. The next step is to work smarter with automation.

- Switch to electronic data recording and maintenance to protect regulations and data integrity.

- Implement the latest technology to reduce paper and the complications of manual workflows.

- If all the documents are stored in a single repository in a centralized system, it will be easier to access it anytime to make faster decisions and impactful change management. The technology ensures document safety and also with its traceability features, it can track any appropriate documents anytime.

- Integrate technology with manufacturing plants to monitor all the actions in a single system to get appropriate data representation which helps in getting better insights.

- Execute a strategic quality control structure in place to improve workflow and manage all the documents that will help in improving the quality of the product.

- Deploy an automated system where all the data is available in one place. Information such as complaints, logs and regarding delays can help in addressing the non-conforming issues.

Benefits of ERP for Quality Control in Pharmaceutical Manufacturing

Enterprise Resource Planning Software is an advanced system to maintain the high quality of the product by seamlessly reducing wattage and lowering operational costs. It has multiple features which will assuredly help in meeting all the regulatory requirements and assist in maintaining product quality.

- It helps in complying with all regulations.

- It prevents the circulation of counterfeit products and maintains brand authenticity.

- It has robust features to secure all distribution channels.

- Immediately acts by providing insightful information during recalls and claims.

How does ERP for pharmaceutical business help in maintaining stringent quality control?

An advanced ERP in pharmaceutical industry will have quality control functionality. And these features should oversee processes from the sourcing of raw materials to the post-manufacturing stage.

Purchase of raw materials

There is a lot of ERP software available in the market. But an ideal system will help the business to buy from a verified supplier.

As soon as the raw resources arrive, it has to undergo quality inspections and checklists to ensure that the materials are safe to use. All the materials will undergo a standard quality testing procedure and the records will be stored in the system.

Prominent ERPs like Sage X3 have recipe management functionality to manage recipes and to track details on why, when and who changed them.

Manufacturing stage

ERP keeps track of all the production processes from the beginning. After the inspection of the raw materials, it helps in efficiently managing and tracking recipes. Further, it helps in adding the right measure of raw ingredients with its units of measure feature. It schedules the entire manufacturing process and executes it promptly. Each stage is documented and recorded, as it will be later beneficial to address the compliance requirements and to trace if there is something wrong with the production process.

Quality assurance

After the completion of the manufacturing process, it is tested vigorously to ensure that it follows all the quality control standards. After the manufactured product enters the distribution process, ERP tracks the product location and the status of the shipment with its Lot/ batch serialization tracking feature.

In case a batch of products had to be recalled, it can be immediately done with the unique serial numbers which ERP systems can track efficiently.

Conclusion

Implementing an ERP solution can significantly improve pharmaceutical quality control by providing real-time data tracking and analysis capabilities and by improving collaboration across departments. With the right ERP, the company can meet compliance requirements, and maintain constant product quality. Additionally, executives can integrate quality control data with other business data to make insightful decisions and improve all the operations of quality control.

So it’s a perfectly right decision for pharmaceutical companies to invest in an ERP in order to stay competitive to ensure product safety and efficacy. It will benefit both the company and the consumer.

Sage X3

Sage X3 for the pharmaceutical industry offers robust functionalities for quality control. With this ERP, businesses can automate processes like testing, documenting and meeting all the compliance requirements. Sage X3 has real-time traceability features to track product details. It is inbuilt with collaborative tools so that all the departments can access the data from quality control to further proceed with their operations.

In addition, it has industry-specific features for pharma businesses to achieve better quality control and to get better outcomes.