Summary: Advanced Planning and Scheduling software involve managing processes that help maximize resource capacity and optimize raw materials within a manufacturing facility. This software plays a critical role while optimizing resource utilization during complicated manufacturing operations. APS systems use accurate mathematical algorithms for managing complex manufacturing activities across short, mid, and long-term durations inside a manufacturing facility.

The essential features of APS systems include production scheduling, capacity planning, and material requirement planning (MRP). Although an Enterprise Resource Planning (ERP) software performs these activities on an elementary level, it lacks the strategic decision-making functions of an APS software. So, you will lose essential capabilities such as material distribution, bottleneck visibility, production planning & scheduling if you haven’t yet installed this software in your manufacturing facility.

>>>Also Read: 3 Advantages of using MRP and MPS in ERP Systems to Meet Increased Demands<<<

5 must-have components of APS software

Let’s dive deep to get a detailed understanding of the five most important attributes of APS software and how they will help your manufacturing facility.

1. Production Planning

Conceptualizing, manufacturing, and selling a product are the most critical activities of any business. Production planning plays a significant role for manufacturing companies because it consists of ordering raw materials, converting them into finished products based on a specified schedule, and storing them in the warehouse. A production plan is a manual that contains instructions regarding the processes, activities, and sequence of steps that help achieve the production target within the specified duration. The primary challenges during production planning are managing resource capacity, availability of raw materials, and forecasted demand.

2. Demand Planning

Demand forecasting is crucial for every company as it helps understand which products have the highest sales potential. It depends on multiple factors such as:

- Types of goods

- Price of goods

- Competitive forces in the market

- Alternative product information

- New technological innovation

- Economic development in a particular region

- Changing customer preferences

A company can use the following forecasting techniques to calculate demand.

- Survey-based techniques: These techniques focus on gathering data from field experts, established scientists, employees, and customers. Commonly used techniques include the Delphi method, expert opinion poll, focus groups, and market experiments.

- Statistical methods: These methods depend on past data to derive valuable insights and discover hidden patterns. Typically used statistical methods include barometric, projection, and econometric methods.

- Machine learning capabilities: Machine learning is the newest method that companies across industries are implementing to forecast market demand, select suitable goods, adopt appropriate budgeting processes, evaluate the competition, brainstorm the right pricing strategy, and install appropriate technology that enables maximizing profits and minimizing operational expenses.

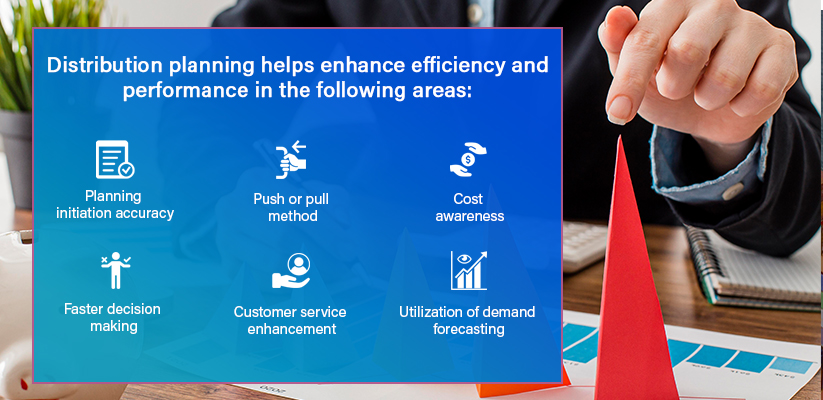

3. Distribution Planning

Distribution planning refers to efficiently managing all aspects of the supply chain and ensuring that finished goods reach all distribution centers and then the final customer on time. APS systems help achieve these objectives by enabling the user to set inventory control parameters and monitor & track time-based inventory requirements.

Elements of distribution planning are:

- Lead times

- Transit time

- Safety stock number

- Forecast demand

- Real-time inventory level across each distribution center and warehouse

- Ordering raw materials from suppliers automatically

The primary goal of demand planning is to bring operational costs down. The best way to do this is by shifting a significant chunk of the business to e-Commerce portals instead of relying on brick and mortar stores.

Another challenge that makes distribution planning crucial is understanding the fast-changing market trends and customer preferences. Last year’s data is outdated and might not be as relevant today. So, distribution planning keeps a tab on available inventory and monitors stocking & warehousing prices that help minimize logistics costs.

4. Production Scheduling

Production scheduling refers to assigning different processes, raw materials, and resources to varying products. The primary function of this module in the APS software is to increase the efficiency of the production process, make them cost-effective, and ensure that the final products reach the customer on time.

In a recent supply chain worldwide survey, 623 respondents pointed out the following critical KPIs of a production scheduler:

- Production time (27%)

- Inventory turn (28%)

- Production service rate (29%)

- Cost reduction (35%)

- Daily performance (40%)

Production scheduling is executed in five stages:

- Planning: This stage is subdivided into 2 phases, namely static and dynamic. Static planning refers to processes that don’t undergo any change. On the other hand, dynamic planning relates to activities that can change/transform over a while. Planning includes gathering and examining timelines, available resources, budgets, and staff.

- Routing: This stage defines the path and the sequence of steps required to manufacture finished products from raw materials.

- Scheduling: The user defines the time and date for the completion of each production order in this stage. You can create the following types of schedules in this process:

i. Master schedule: This includes controlling and managing routing steps, people, resources, and much more.

ii. Retail operations scheduling: This type of scheduling provides the sequence of steps for manufacturing retail products sold in e-Commerce portals and brick and mortar stores instead of being purchased directly by the customer.

iii. Manufacturing/operations schedule: This includes routing steps only.

- Dispatching: This stage involves issuing orders to move resources, people, and goods from one place to another in the production scheduling process.

- Execution: This is the last and final stage that deals with the execution of the production scheduling process.

5. Transportation Planning

Transportation planning is a broad term that includes multiple phases, such as strategic, operational, tactical, and planning. APS software allows companies to take care of all these phases by using planning algorithms, varying information levels, and different data granularities over time.

APS software provides the following benefits:

-

Faster decisions making

APS software doesn’t rely on sequential processes. Instead, it depends on parallel data processing that allows logistics planners to receive real-time data on transport events. This information helps make decisions quickly and efficiently. Moreover, APS systems eliminate lag, ensuring that up-to-date information is available and can be accessed and shared between different stakeholders and companies in real-time.

-

Uniform planning

APS software’s uniform planning approach breaks down information silos that restrict critical business information flowing between relevant stakeholders. Another benefit of this approach is that it balances intralogistics and transport costs. For staying relevant in modern times, APS systems also allow transport companies to monitor and track their “Green Footprint” by reducing climate change emissions during the planning phase.

-

High elasticity

APS software is primarily built for improving the resiliency of supply chain cost plans and risk management by real-time replanning of supply and transportation relationships. Its high elasticity comes from updating data regularly in operational planning and overplanning.

-

Accurate decision making

APS software works as a communication bridge between multiple parties by providing access to relevant data. They can fine-tune the data with several constraints and goals and use new algorithms with embedded analytics allowing more proactive decisions in the supply chain.

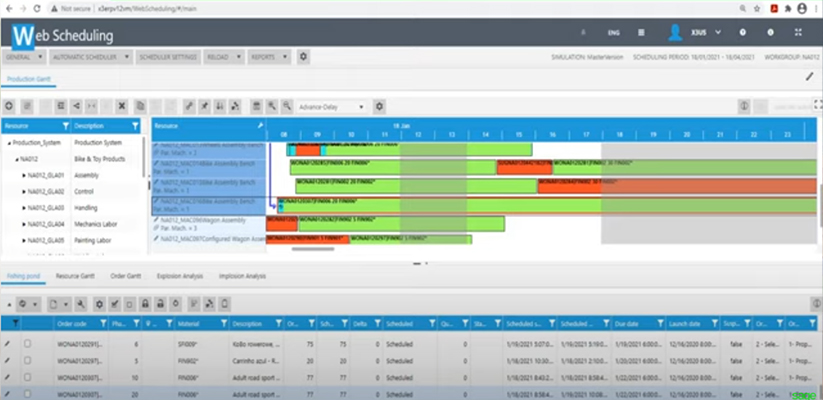

Sage X3 web scheduling — A modern way to plan your production processes?

Sage X3 web scheduler allows fine-tuning and manual editing of production processes. It will enable you to use manufacturing resources effectively and ensure that delivery dates are met and achieved on time. It also helps minimize setup time, optimize production plans, and manage production constraints like labor, materials, and tools.

Sage X3 web scheduler will organize the entire production chain by allowing you to:

- Manage customer and work orders

- Identifying tooling constraints and material

- Identifying bottlenecks

- Minimizing queue time

- Responding to disruptive events quickly

- Handle urgent orders and priority changes

- Get 360-degree visibility into shop floor issues

The 6 essential components of the Sage X3 web scheduler are as follows:

1. Powerful and flexible

Sage X3 can create diverse scenarios based on what-if analysis support and varying heuristics. In addition, the flexible scheduling option enables defining frozen periods, scheduling horizons, and other parameters like priority management, material management, launch dates, and machine outings.

2. Flexible and automated scheduling

Planning managers can decide whether to optimize the plan for a particular area or the whole factory. Sage X3 web scheduler also allows managing unexpected events like machine downtime and new order priorities.

3. Discrete production environments

Sage X3 web scheduler filters and incorporates planning data and uses it to optimize the scheduling plan of different departments of a plant.

4. User-friendly interface

The web scheduler has an excellent user interface that allows the planner to adjust and analyze the plan manually. It makes scheduling easy to use and intuitive. Further, it provides multi-department segregation and real-time constraints verification.

5. Process production environment

Sage X3’s webs scheduler optimizes the production sequence according to planned work orders sent through the MRP.

6. Analytics support

Users can examine current scheduling simulations through standard overview dashboards. Moreover, you can also create new reports with in-memory data through the layout manager.

For more information on how to use the Sage X3 website scheduler, watch this in-depth video.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.