What is in a Barcode?

Barcode is a machine-readable code in the form of numbers and a pattern of parallel lines of varying widths, printed on a commodity. Barcode contains information about a product like; price & weight of the product, date of manufacturing and expiry, name of the manufacturer etc.

What is the purpose of barcoding?

Barcodes are applied to products to quickly identify them. Among their many uses, barcodes are typically used in retail stores as a part of the purchasing process, in warehouses to track and manage inventory and on invoices to help with accounting. Barcode setup can also be done in Sage 300Cloud by following few simple steps.

Once the barcode configuration is done, then the inventory can be Moved In or Moved out using the barcode which has been assigned.

In Sage 300Cloud there are two different types of barcode available viz Serial Barcode and Lot Barcode. In Serial Barcode one serial number can be used only once and for one inventory unit, where as a Lot Barcode can be used to define a lot of inventory unit i.e. in one lot there can be multiple item units.

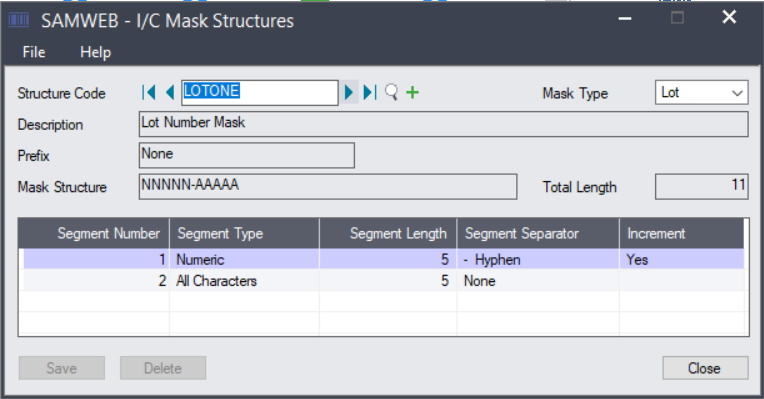

For configuring the Barcode the first step is to define the Mask Structure or the Barcode Solution format. The example below can be used for the same:

The Structure code is a name or code given to the Barcode structure. The description tab shows the detailed description of the Structure Code defined. You can provide a prefix for the Barcode by describing the Prefix type like (. , -, *, /,\,#, etc.). The Prefix can be left blank as well.

The next step is to define the mask structure for the barcode, which is the length of the barcode. In the above example, the total length of the barcode is 11 characters, where a (-) separator is used to separate the Numeric and other characters. Finally, the Increment tab is set to ‘Yes’ as generating a new barcode will be incremental in nature.

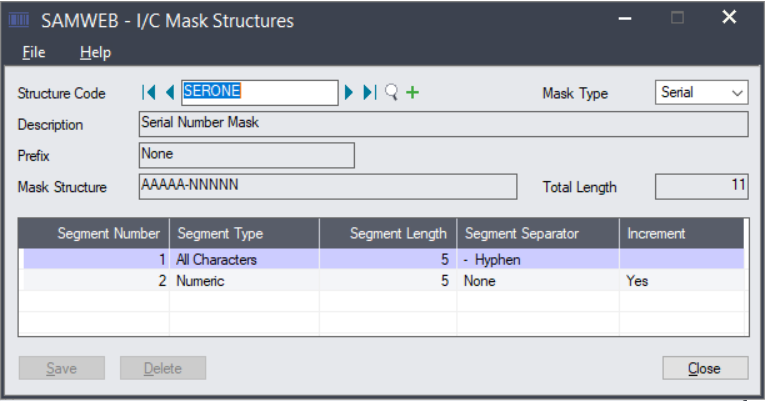

The same configuration steps can be followed for Serial and Lot Barcode types.

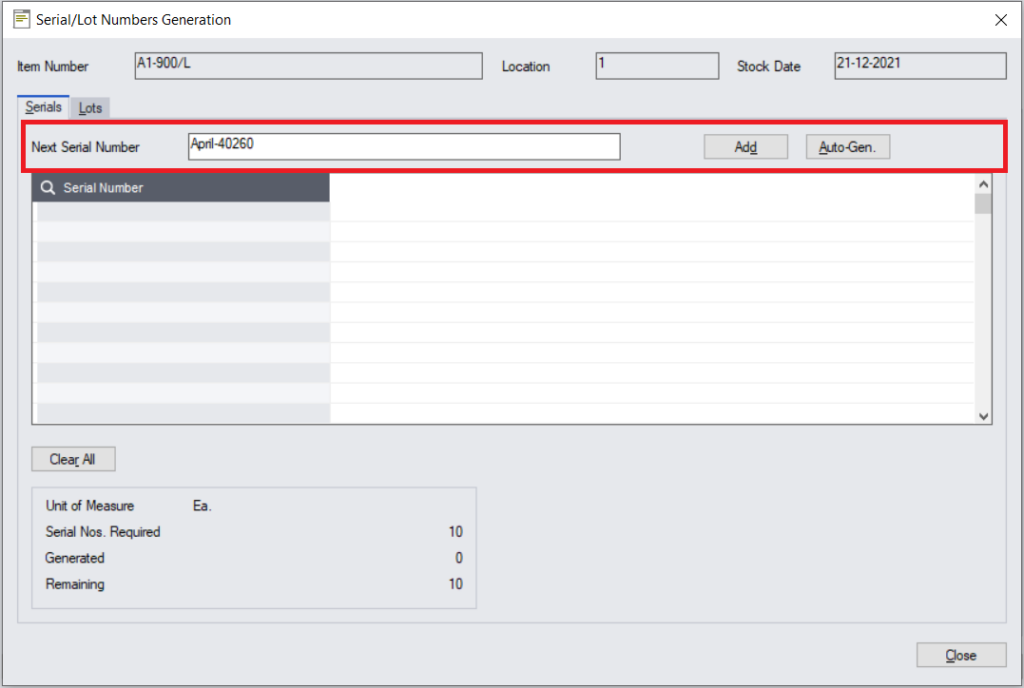

The below image is an example of a Serial Barcode.

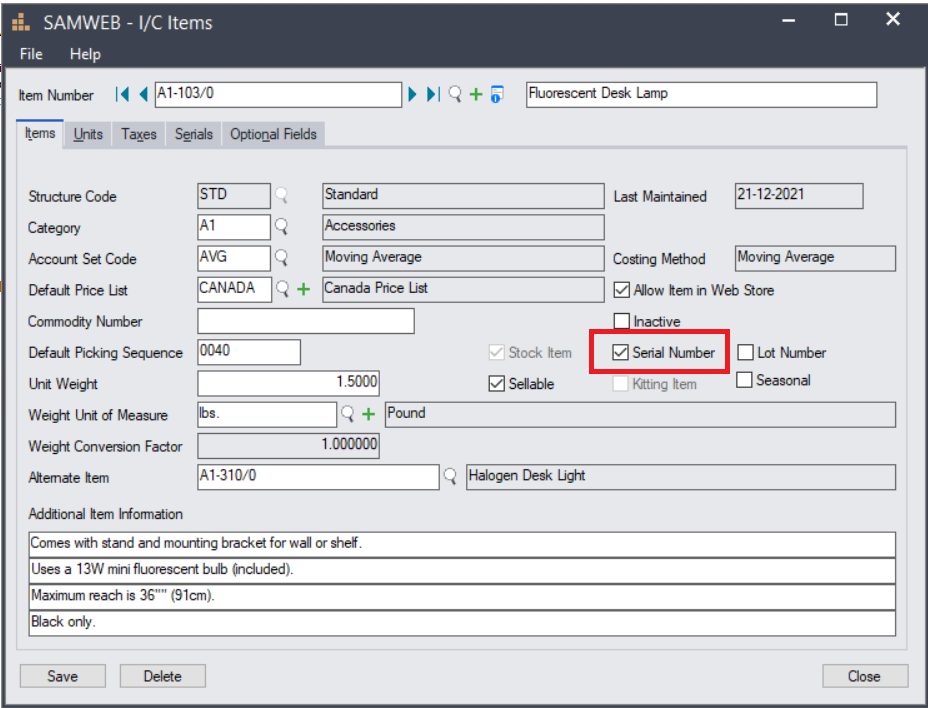

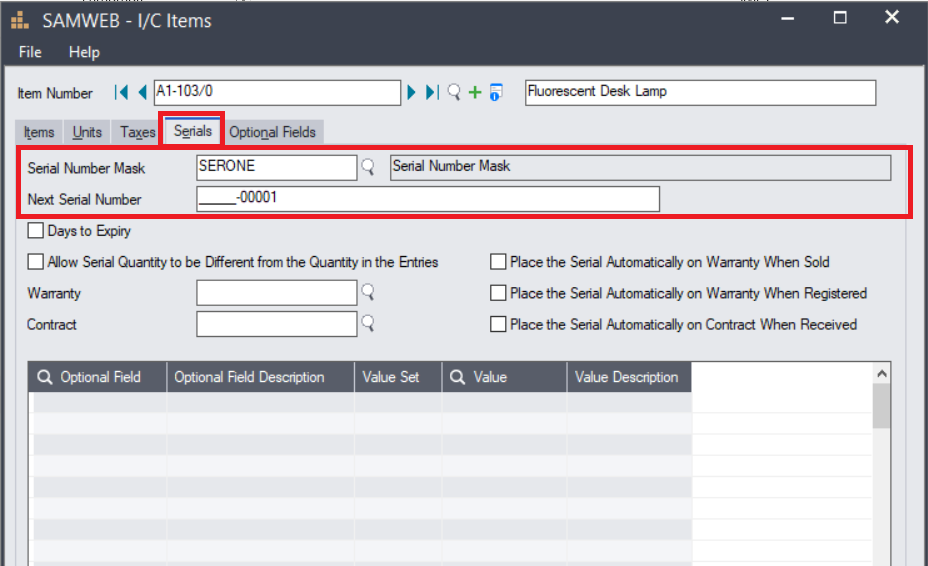

Once the Mask Structure is defined, the same needs to assigned to the item number in the Item master.

In Sage 300Cloud, you can maintain Multiple Mask Structures if the company has different structures for different items. Then, after creating the Mask Structure, the appropriate can be assigned to the items accordingly.

Also, both Serial and Lot number can be assigned for the items in Sage 300Cloud.

After all the configuration and setup is done, the item is available to be used with the Barcode functionality. The Barcode functionality is primarily used in two screens, viz GRN screen in PO module and Shipment Screen in OE module. The barcode functionality can also be used for Internal Transfers, Receipts, and Shipment.

The main benefit of the barcode functionality is that much information can be stored along with the quantity of the item in a barcode.

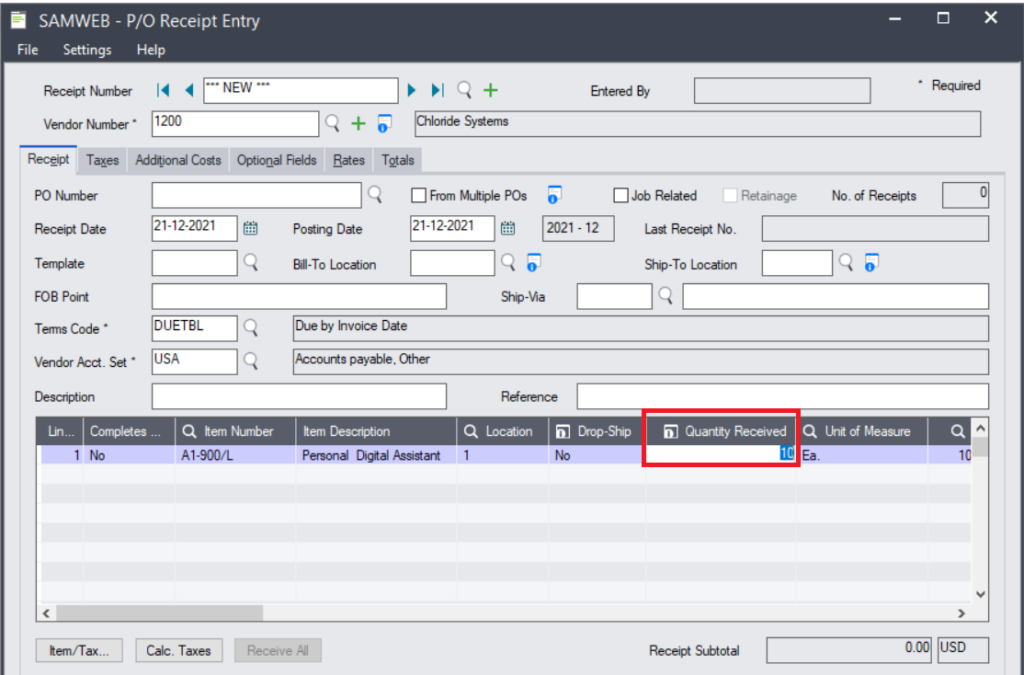

Use of Barcode while making GRN entry in Sage 300Cloud: –

The use of Barcode comes into the picture while making a GRN. During this stage, the stock moves into the Inventory and physical location.

When the user scans the Barcode the quantity gets automatically captured in the screen for the items that is getting scanned. The other option is to manually select the barcode for the finder option which is available in at the screen level. The other benefit of the barcode module is that if the user tries to scan a different barcode or different mask structure then the system throws an error, there is also a validation for the quantity as well, which helps the user to scan the exact quantity which is there in the entry.

Once the zoom button or the I button is clicked the window opens for the Barcode input.

The user has 2 options to assign the barcode for the inventory.

- By manually adding every Barcode number.

- By giving the first barcode and then clicking on the Auto-generate option, which will generate the barcode in an incremental manner.

The above Scenario is used when the Barcode type is a Serial Number.

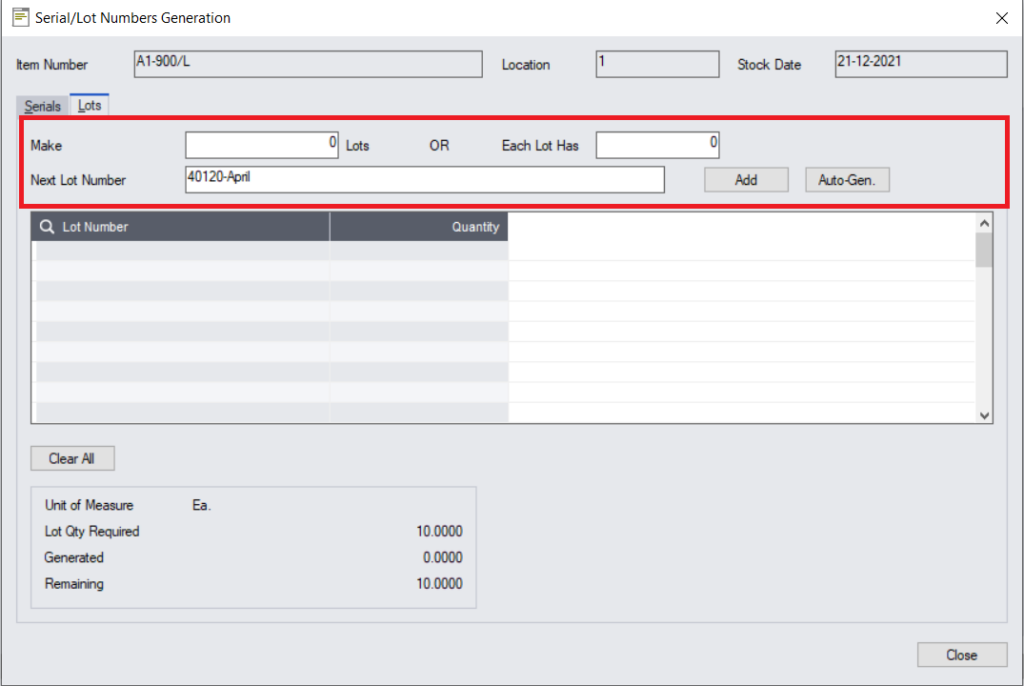

In the case of the Lot number, there is a change in the Barcode assigning screen. Refer below for the explanation.

The change is that the user has to instruct the system to make the number of Lots or provide the Quantity of items in each lot.

For example, if the GRN Qty is 10, the user can make 2 lots that will have five quantities in each or else the user can define that each lot has 2 quantities and the system will generate Five different lot numbers. Again, the user can give the lot number sequence manually or by clicking the Auto-generate button the system will generate the Lot number in incremental format.

Once the Entry has been posted and the Day End Process is performed, the Barcode will be assigned to the item for the particular quantity and the same will be reflected in the Inventory.

Once the Barcode is available in the Inventory, the same barcode is used for the Shipment of the items.

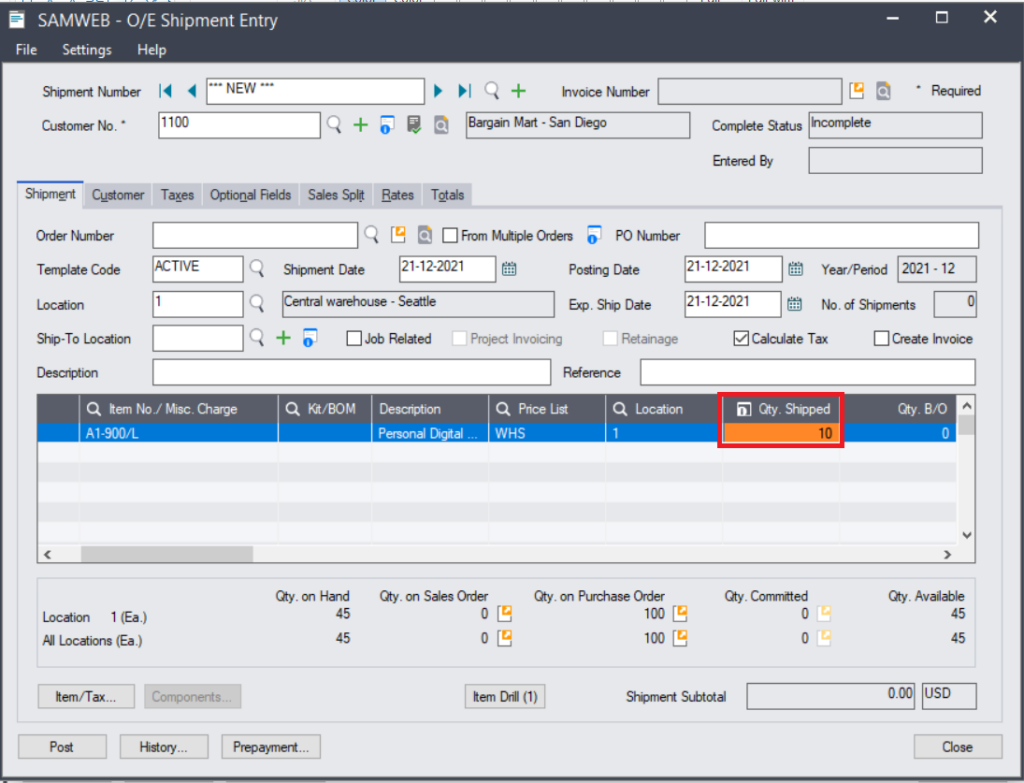

Use of Barcode while making Shipment entry in Sage 300Cloud:

For moving out the barcode from the system the OE Shipment screen is used. Once the item are ready to be shipped the user will again select the item and the quantity that is to be shipped to the customer.

The Zoom or the I button is also available is OE Shipment Screen which is used to assign the Barcode of the Quantity. After opening the Screen, the user has 3 options to assign the barcode which are to be shipped out.

- Auto Allocate:- Which will automatically allocate the Barcode in ascending order.

- Auto Allocate From :- In this criteria the user will have the option select the range of the Barcode which needs to be assigned.

- Manual selection:- In this option the user has to select each barcode which has to be assigned manually that needs to be shipped.

The above criteria is applicable for both Serial and Lot barcode

Once the entry is posted and the Day End Process is performed the Barcode is moved out the system.

In Sage 300Cloud there are few reports to track the Serial and Lot Barcodes along with the transaction for the same.

- Serial/Lot Transactions

- Serial/Lot Number Qty On Hand

- Serial/Lot Number List

- Serial/Lot Stock Listing

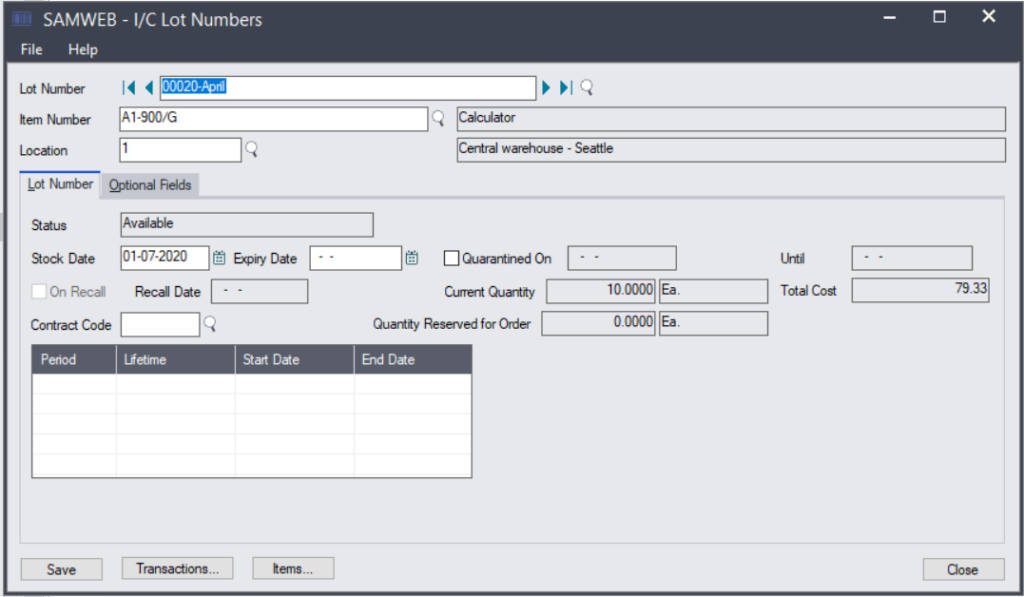

Also the Status of any barcode can be reviewed from the screen itself, for doing the same Lot Number and Serial Number screen is used which can be found in IC Module in the IC Item and Price List sub-module.

In the above image the status the Lot Number is given along with the Total Cost and the Quantity which is available in the Lot Number.

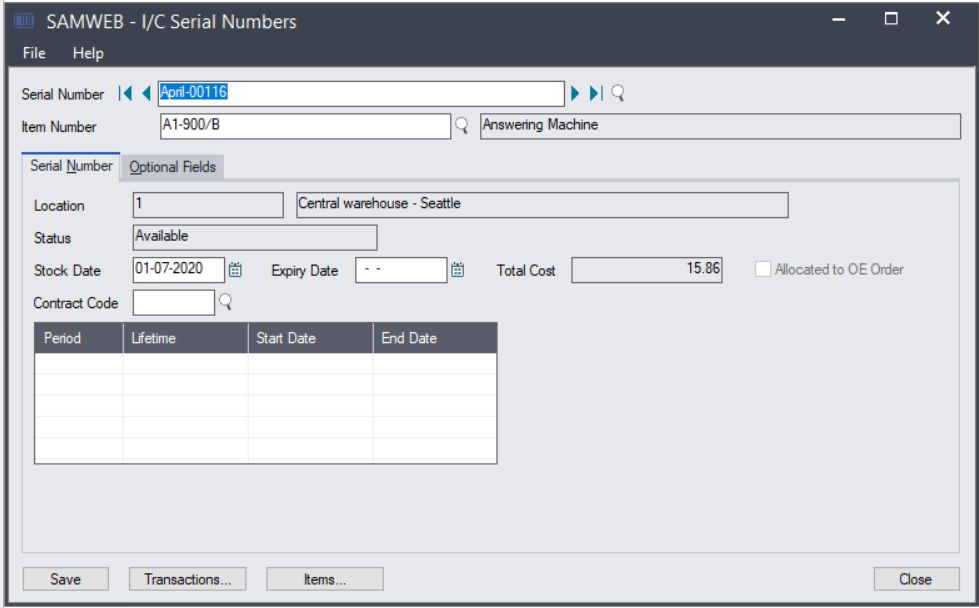

In the below image the same status is shown for the Serial Number.

The Barcode functionality is very user-friendly in Sage 300Cloud. It’s beneficial for making entries flawlessly that ensures the business’s smooth functioning and maximum efficiency.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.