Companies nowadays are completely dependent on technology to perform their functions efficiently. Businesses are more dynamic and competitive than before finding innovative methods to stay relevant and recent in the market. The solution for this tough situation is fully automated ERP software, an advanced technology helping businesses to perform their everyday operations brilliantly.

ERP is used by businesses across the world to ease the complexity of business processes. Globally, there is a constant need to gain full control of the supply chain operation, meet customer demands, and maintain product quality, and traceability of the product throughout the production cycle till it reaches the end user. A fully functional and effective enterprise resource planning software can solve these issues.

Modern ERPs can be customisable solving the requirements of any industry. Most businesses are opting for a customized ERP to attain seamless function of the business.

Chemical Industry

Industries dealing with the production of chemical goods are categorized under the chemical industry. India’s erp for chemical manufacturing industry is vast and is one of the significant components of the country’s economy.

Now, due to the burst of innovation, chemical manufacturers have to keep up with infinite customisations to meet the expectations of the customers.

Companies manufacturing chemical goods have dual challenges to face- the first thing is to meet high production standards and the second is to stay relevant to the increasingly competitive market in the midst of digital transformation.

Challenges faced by Chemical Industry in 2023

The chemical industry is vast and has its own set of challenges that businesses have to deal with. So here are some of the challenges that businesses encounter in 2023.

- Global recession affecting businesses.

- Rising energy prices.

- Inflation of raw materials.

- Supply chain issues across the globe.

- Demands of the public to move to sustainability.

- High-priced logistics especially, trans-ocean shipments.

- Cultural erosion and reshoring of companies.

ERP for the Chemical Industry

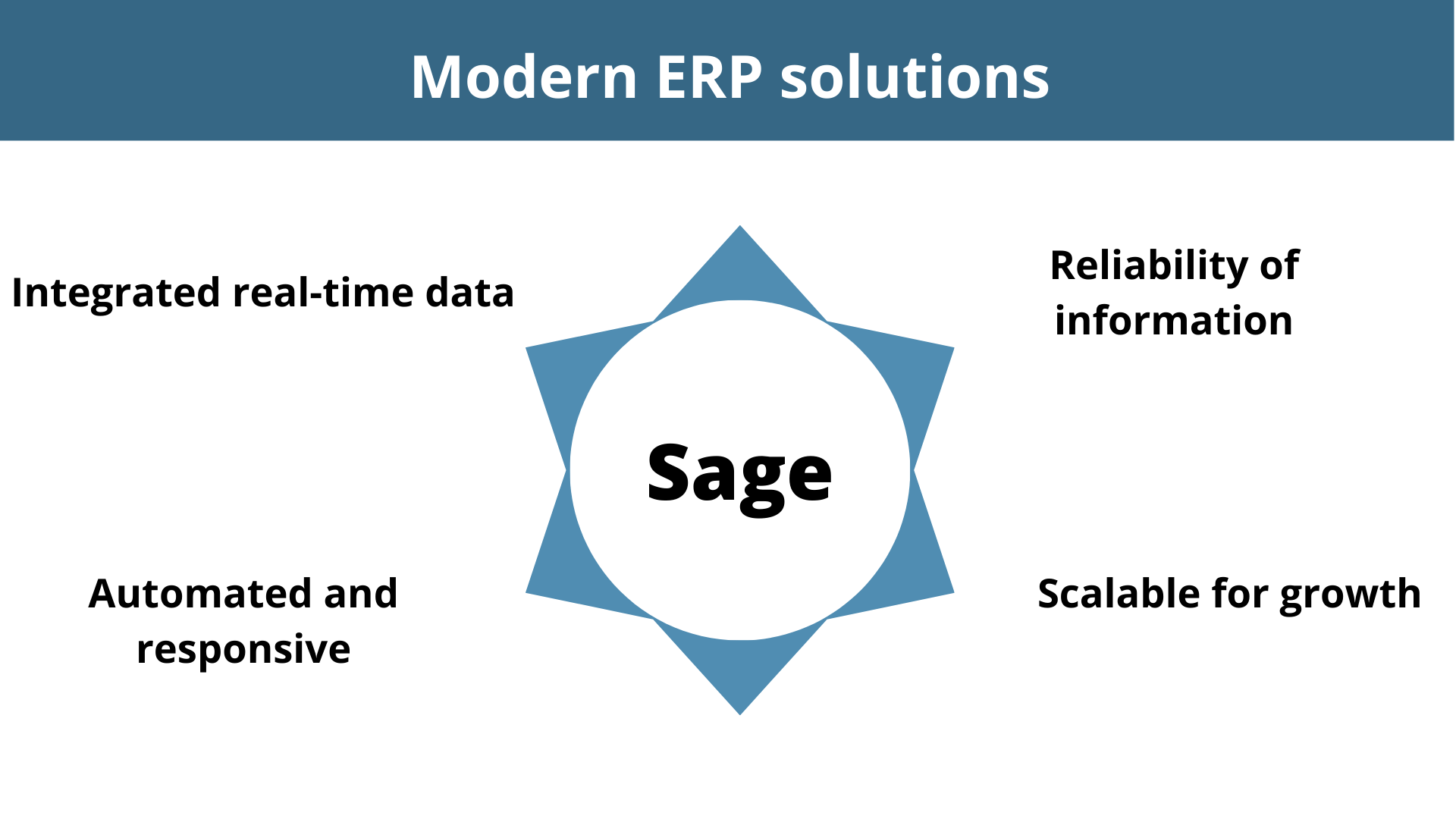

So businesses engaged in the production of chemical goods need automation to manage their processes effectively. Modern technologies like ERP solutions have the capability to help these industries to harness their operations and have a competitive advantage. Cloud-based and smart technology can help this business to increase productivity and bottom line.

So, there are also other technologies that integrate with the ERP to give maximum benefits to the company. For example, technologies such as AI which have predictive tools can effectively respond to changing market demands and trends. IoT and machine learning are also an advantage for the chemical industry to increase productivity and resources.

Technology for the chemical industry should be able to fulfil the following benefits.

- Show accurate demand forecasts.

- Planning the raw materials required for production.

- Allocate resources efficiently.

- Effective warehouse management.

- Traceability of the product batch-wise and tackle recalls systematically.

- Efficient logistics management.

<<<Also read: Efficient Supply Planning in the Chemical Industry>>>

Benefits of custom ERP for the chemical industry

ERP can be customized to meet the industry’s requirements. ERP for the chemical industry can streamline business operations, distribute tasks and gain control of the entire business. Let’s discuss more about the benefits of custom ERP for the chemical industry.

Increased collaboration

A team has its own unique structure and approach to performing operations. A custom ERP unifies all the teams activity to a centralized database to avoid unnecessary confusion.

Formula management

In the chemical industry, formula management is crucial. Accurate measurements, quantities, concentrations, qualities, reactions and concentrations are essential for this industry.

A custom ERP helps in adding accurate amounts of raw materials in the correct unit of measure. It can also help you formulate the cost of the product based on the current costs of the raw materials.

Inventory management and control

In order to gain control of your business traceability of the product is vital. Information on quality control, expiry dates, and other significant elements is crucial.

A custom ERP automates all the processes connected to the quality control data with all the batches and lots. In addition, it can be integrated into all the warehouse and shipping locations to manage the delivery of the products.

Product innovation

In a custom ERP, all the teams share information in a centralized system helping the research and development team to understand the future demands and innovate products.

Supply chain control

In any company, supply chain operation is a critical function. Most businesses aim to gain complete control of the supply chain to maintain the smooth operation of businesses. To attain this efficiency, there should be visibility of the entire supply chain process.

Chemical ERP can help in harnessing the supply chain process of the company. Manage raw materials, minimise costs, reduce wastage and boost profitability with a custom ERP for the chemical industry.

Responsive manufacturing and agile

A chemical ERP helps in being flexible to understand the demand for the product in the consumer market. Suppose, as a business owner, you wish to change the production plan, you can easily track the people involved in the supply chain network and inform them so that they can adjust to your plan. These manufacturing plants are altered based on the change in marketing and sales activity.

A custom ERP helps in gaining higher responses to the changes made, boosts synchronisations, reduces errors, and real-time information helps the tasks to be completed faster.

Remote access

A cloud-based custom ERP can help a user access the system from any device and from any location. It is more useful for employees out at an expo talking to a potential customer.

Mobile ERP is highly user-friendly which helps to get insights to close deals and negotiate terms.

Simplify production complexities

A custom ERP provides flexibility to make changes in products based on supply and demand. It also ensures that the entire manufacturing process is carried out without any hindrance. It is capable of identifying risks in prior.

Safety and quality maintenance throughout the entire manufacturing process

Traceability of all the processes in the ERP system helps to maintain the safety and quality standards of the product.

Compliance

It is crucial for the chemical industry to stay compliant with the regulations. Compliance and safety regulations are framed for this industry to avoid industrial accidents and to keep everyone safe as this sector deals with manufacturing hazardous chemicals.

Custom ERP has features to test warehouse conditions, ingredients, and temperature. And they have reporting capabilities helpful to fulfil compliance standards.

<<<Also read: Meet Chemical Regulations through integrated Traceability data>>>

Conclusion

A custom ERP system for the chemical industry will solve all the challenges that arise every day than a normal ERP. In addition, it adds varied benefits to this industry helping it to increase productivity, follow all the compliance and safety standards and maximise profits. Choose the right ERP benefiting your industry.

Sage X3

Sage X3 is a perfect business management solution helping businesses to achieve productivity and growth faster. Its implementation is quick and helps businesses to function efficiently. It optimizes all the core functions of the business helping to reduce operational costs and wastage of resources. Implement Sage X3 for your business and begin your journey to success. To know more about our product, connect with us today.

Sage Software Solutions is a leading IT company with an array of advanced ERP Software solutions. Our proprietary products — Sage X3 and Sage 300, will help you cut operational expenses, improve business productivity, increase operational efficiency, forge robust customer relationships, and strengthen associations with vendors, suppliers, and distributors.

So, if you are looking to reinforce your business fundamentals and emerge as an industry leader, then please schedule a call with one of our sales representatives.