What is ERP for Energy Industry?

ERP for energy industry refers to Enterprise Resource Planning, which is a specialized software that streamlines energy industry-specific processes and activities, such as production planning, resource allocation, equipment management, workforce management, cost tracking, and energy transmission and distribution.

Overview of the Energy Industry

India’s energy sector is composed of electricity and power distribution companies, oil and gas companies, coal mining and transportation companies, and the renewable energy industry. India is the fourth country in the world with the largest installed renewable energy capacity, including large hydroelectric plants. India’s energy sector has witnessed substantial growth, supported by the adoption of modern technologies such as ERP software.

India has a total installed power capacity of 401.8 GW, which consists of 280.5 GW of thermal plants, 90.7 GW of renewable plants, and 29.6 GW of hydroelectric plants. The energy sector is one of the most diverse and a major source of employment and economic growth. Different factors contribute to the growth of the energy sector in India. The Indian population and Indian economy are rapidly growing, resulting in heightened energy demand. India’s energy sector consists of various companies involved in drilling, refining, exploring, and developing, in addition to those involved in solar and renewable energy sources.

Challenges Faced by the Energy Industry

-

Inadequate Power Generation

In recent years, India has undergone rapid economic growth. India’s commercial energy supply must grow at a minimum of 7% to meet the current market needs. However, due to corruption, low-quality infrastructure, poor equipment maintenance, and disregard for energy conservation measures, the power generation capacity of the energy industry remains insufficient to meet growing market demand.

-

Underutilized Plant Capacity

Underutilized plants are those that generate less revenue despite excess capacity. These plants incur higher maintenance costs and lead to reduced profits. Many of India’s power plants are underutilized. They are old and suffer from poor transmission and distribution infrastructure. Energy companies run them at a lower Plant Load Factor (PLF) to avoid breakdowns, accidents, and similar issues.

-

Limited Role of Private and Foreign Investors

The Government and public sector largely dominate the Indian energy sector. Although the Government of India is trying to encourage private sector participation in the energy sector, it plays a very limited role. The lack of participation from private and foreign investors has led to less innovation and efficiency in the utility industry, ultimately resulting in higher overload costs and a lack of pressure to remain competitive.

-

Shortage of Coal and Raw Materials

Many companies operating in the energy sector are running out of coal and other raw materials, which has led to power cuts in several Indian states and impacted economic growth. The lack of fuel, gas, and other raw materials has forced the power plants to operate at a lower capacity, leading to idle plants, reduced production, and higher energy costs for the ultimate customers. Energy companies mitigate the impact of insufficient raw materials by finding alternate energy sources.

-

High Transmission and Distribution Losses

An electricity transmission and distribution loss is the amount of electricity lost while transmitting it from power plants to end customers. In 2022, India suffered a T&D loss of 24%, making it one of the top countries with higher T&D losses. When an electric power company in India generates 100 units of electricity, only about 76 reach the customers, and the remaining units are lost. Old and outdated infrastructure can make electric wires and equipment more resistant and cause higher T&D losses. Electricity theft and defective meters are also among the reasons.

Future Trends in Energy Industry

-

Transition to Renewable Energy Sources

Indian power companies are moving from traditional thermal energy to renewable energy projects. These sources offer net-zero carbon emissions and fewer pollutants than their traditional counterparts. India has set an ambitious target of achieving a clean energy future by 2030. The renewable energy sector is a growing sector that is creating new economic development and job opportunities.

-

Green Hydrogen

The Indian government is emphasizing several policies to promote the use of Green Hydrogen. Green Hydrogen is considered a potential game changer for the energy sector because it is a clean and sustainable fuel that doesn’t produce greenhouse gas emissions. Unlike other renewable energy sources, its use can decarbonize power generation, transportation, manufacturing, and other sectors.

-

Penetration of Smart Grids

India is heavily investing in Smart Grids that offer various benefits over traditional grids. Smart grids provide efficient electricity transmission, significant cost savings, and lower power costs. They are less likely to suffer major disruptions. They support the quicker restoration of electricity after power interruptions. Moreover, they help reduce greenhouse gas emissions and combat climate change by integrating renewable energy sources into the grid.

Features of Energy ERP Software

-

All-encompassing System

Energy companies usually use small Energy Management tools that look after the production, consumption of units, planning, and control of the systems. An ERP system is an all-encompassing system that provides Inventory Management, Quality Assessment, General and Ledger Management, and other functionalities under a single roof.

-

Project Management

ERP implementation can improve various tasks involved in Project Management in the utilities sector, such as scheduling, budgeting, and reporting. It allows project managers to focus on more strategic tasks, get visibility into project operations, provide a single source of truth for all project-related data, and deliver projects more efficiently.

-

Localization

Many energy companies operate on a global level and have customers from different countries and continents. ERPs combine global reach and local knowledge to provide personalized experiences. They are configured to operate in different countries with the local currency and language and comply with the local tax regulations to avoid fines and penalties.

-

Field Service Management

The Field Service Management Software lets businesses manage off-site employees and the resources they require to perform their day-to-day activities. It involves various activities such as tracking service appointments, field service activities, and requests.

-

Reporting

ERP software for energy comes with standard reporting functions tied to specific business tasks. It generates automated reports about market trends and consumer behavior, inventory analysis, production schedules, and the financial health of the company. This can be a great time- and effort-saver.

-

Process Standardization

ERP helps industries of all scales track and measure the performance of all processes, identify room for improvement, and take corrective measures. By standardizing all business processes, the company can ensure that the products are consistently produced at high standards to reduce costs associated with defective products and improve customer satisfaction and loyalty.

You May Also Like: ERP for Oil and Gas Industry

Benefits of Energy ERP Software

-

Panoramic View of All Business Costs

Enterprise Resource Planning software helps decision-makers build robust financial strategies to track and control overhead, labor, and operational costs. Businesses can track inventory levels in real-time, reduce stock-outs and over-stocking incidents, and benefit from significant cost savings. The online procurement management system helps negotiate better prices and terms to ensure the right quantity of inventory is on hand at the correct cost.

-

Comprehensive Asset Management

One of the modules of ERP systems is Asset Management. It helps energy companies track assets in real-time, improve the asset lifecycle, track asset visibility, schedule asset maintenance, and identify ghost assets. Energy industries use the asset tracking system to increase asset reliability and operational efficiency.

-

Predictive Maintenance

Other ERP benefits include Predictive Maintenance of capital-intensive assets. Predictive Maintenance involves using Internet of Things (IoT) sensors and analyzing historical machine performance data to predict when equipment is likely to malfunction. ERP facilitates predictive maintenance to reduce downtimes, extend machine lifespans, maximize asset uptime, improve asset reliability, and reduce the costs of unnecessary repairs.

-

Streamlined Workflows

ERP integrates all renewable energy business processes, such as manufacturing, human resources, financial management, sales, and customer support. This results in improved collaboration and streamlined workflows.

-

Increased Compliance

The energy sector is subject to several regulations and safety and environmental standards set by the Government. The best ERP software in India provides audit capabilities, making it easier to comply with various Government rules and regulations and reducing the number of errors and non-compliance penalties.

-

Maximized Fuel Supply Availability

Flexible ERP solutions keep a real-time record of fuel availability and demand to ensure the energy company has the right amount of fuel storage. It also streamlines the fuel procurement tasks, such as the identification of high-quality fuel suppliers, negotiations for lower prices, and delivery tracking, as part of the cost-saving measures. The custom reports and dashboards help perform in-depth research and identify various ways to optimize fuel supply chain management.

-

Centralized Data Management

The best ERP software stores all the organizational data in a central place, making it easier to access and manage. It also benefits in other ways, such as reduced redundancy, efficient data organizing, better customer relationship management, better risk management, smooth supply chain management, and improved workforce productivity and accuracy.

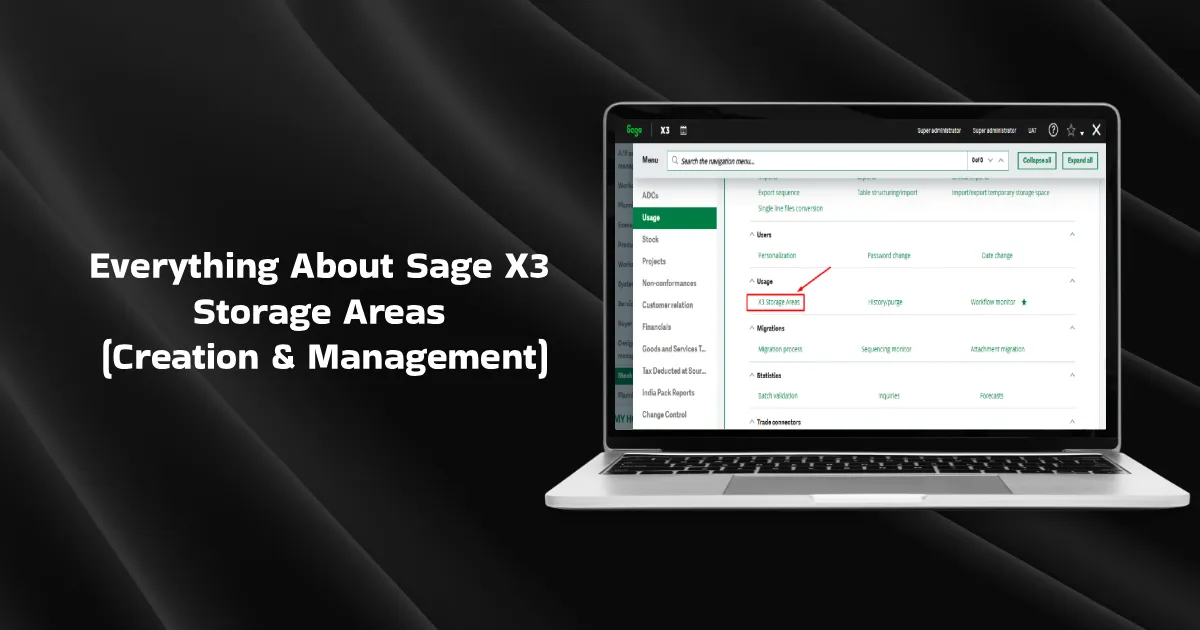

Optimize Your Energy Operations with Sage X3

Energy industry ERP software provides modern-day energy manufacturers with a centralized platform to integrate data from disparate sources and improve overall business visibility. Businesses can streamline their onshore and offshore projects, improve asset utilization and compliance, and look into areas that dampen business productivity to drive sustainable growth.

Sage X3 offers powerful analytical capabilities to help your business map all the needs and requirements and effectively address the various challenges the energy industry faces. It streamlines and automates various tasks, eases the intricacies related to different business processes, and allows decision-makers to allocate and align resources in an optimal manner. Your business can leverage its data-driven solutions, reports, and customized dashboards to perform an exhaustive study, which ultimately improves business functionality and cuts down on unwanted spending.

Frequently Asked Questions (FAQs)

1. What is the full form of ERP in energy sector?

The full form of ERP for energy sector is Enterprise Resource Planning. It is a dedicated tool used by energy companies to streamline their core processes, manage complex processes, and promote a smooth flow of information across different departments.

2. Which is the best ERP for energy industry?

Sage X3 is the best ERP for energy industry that provides strategic insights to track and automate compliance activities, perform detailed risk analysis, monitor energy consumption patterns, track project completion, manage resources efficiently, and generate detailed reports for better control and planning.

3. What are the unique advantages of ERP for energy industry?

The following are the unique advantages of the Energy ERP system:

- Get rid of disconnected systems and manage operations with a unified platform

- Improve equipment lifetime and reduce downtimes

- Streamline compliance-related activities and avoid potential risks

- Prevent over-stocking & under-stocking of inventory and improve market response time

- Get clear insights into your company’s financial operations and make informed decisions.