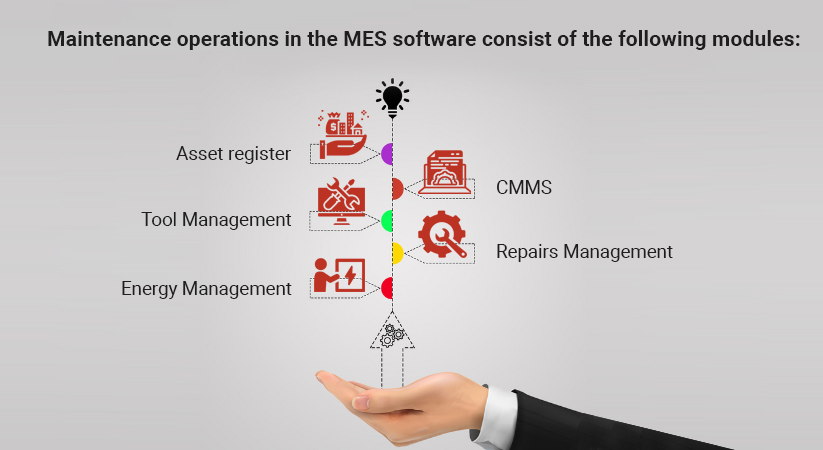

Summary: Manufacturing companies produce finished products in vast quantities that require repair and maintenance for protection against wear and tear. Fortunately, MES software has various modules that improve enterprise asset management, monitor tool life, optimize maintenance activities, record energy & resource consumption, and help reduce energy losses.

Let’s dive deep to get a 360-degree overview of how MES software helps perform repair and maintenance operations:

1. Asset Register

Companies find numerous challenges in managing the performance of diverse assets across the factory, such as production lines, tools, machines, sub-components, containers, measurement equipment, and much more. The asset register module of the MES software creates and updates the history of asset use and activity. They also manage plant equipment across the entire product life cycle, from purchase to decommissioning. You can also set the equipment status like ready, requires cleaning, and many more.

The features of the asset register module of the MES software:

- Capture asset data usage.

- Produce visually-rich reports that depict asset performance and history.

- Set a pre-defined set of rules that allow the machine to change from one to another conveniently.

- Restricts operators from using equipment that isn’t cleaned.

- Generate BOMs for secondary components and spare parts required for maintaining the plant equipment.

- The asset register allows operators to create an asset hierarchy. For example, Facility —> department —> line —> machines —> equipment —> components

The benefits of this module are:

- Better decision making: The MES software stores asset history records that allow operators to make informed decisions.

- Enhance efficiency: MES software records crucial asset data in a single repository accessible to relevant stakeholders from anywhere and at any time.

- Create efficient equipment workflows: Ensures that operators don’t use equipment that isn’t fit to be used or requires cleaning.

<<<Also Read: Asset Disposal Reversal in Sage X3>>>

2. Tool Management

Tools such as extrusion tools, press tools, jigs, moulds, and fixtures play a crucial role in the repair and maintenance jobs. The best part is that several tools produce multiple parts simultaneously. For example, dies and cavities. The tool management module monitors when and where different tools are being used and for how long. It also builds a tool asset library that stores crucial data about each tool and cavity, which helps identify the best tool to execute the desired function.

The features of the tool management module of the MES software are as follows:

- Different tools can be grouped into sets for performing functions that require a collection of tools.

- Track the exact location of each tool in the factory.

- Check the current status of each tool — usable, unusable, requires repairing.

- Get relevant insights into the current level of tool inventory.

- Trace the entire history of each tool.

- Identify when tools are loaded and unloaded during the process.

- Monitor and refer to the multi-cavity tool performance.

The benefits of this module are:

- Tool traceability: Track which tools were used to manufacture which products and when.

- Electronic records: Store tool-related details in a single repository that is accessible to everyone. Moreover, paperless records are highly secure and are difficult to steal, manipulate, and destroy.

- Enhance quality: Check tool/equipment degradation and record measurement based on cavity and tool, which eventually helps make better decisions.

- Monitor tool change-overs: Receive notifications/alerts regarding tool repair & maintenance and respond accordingly.

- 360-degree visibility: Each employee working in the factory will know the current status of each tool and its present location.

3. CMMS

A Computerized Maintenance Management System (CMMS) software helps manage and optimize an organization’s crucial assets. As far as manufacturing setup is concerned, CMMS software keeps complete information about equipment, machinery, and much more. Other features of CMMS software are managing spare part inventory, enabling engineers to record maintenance activities using mobile devices, and helping to plan maintenance schedules based on equipment use.

The features of the CMMS software module of the MES software are mentioned below:

- Execute maintenance procedures over a wide range — from conducting simple checks by line operatives to complicated jobs.

- Execute production counts that are triggered on counts like parts produced or machine cycles.

- Monitor and update the maintenance calendar.

- Plan spare parts and workforce requirements.

- Allow engineers and other technical staff members to collect data through mobile devices while working from the factory floor.

- 360-degree reports display each aspect of the maintenance work: asset history, workload, schedule, workforce hours, and equipment used.

- Use RFID and built-in scanners to search for assets and used parts across the factory floor.

- Allow factory and shop floor workers to check their worklist from anywhere and at any time.

- Create user-defined shutdown calendars.

- Check for how many hours equipment is running.

The benefits of this module are:

- Efficiently manage resources: Plan better to manage resources efficiently.

- Enhanced planning: Forecast labor and spare part requirements, plan maintenance activities, and conveniently check related work.

- Reduce maintenance cost: Instead of arranging schedules based on fixed calendar intervals, you can also arrange them based on usage.

- Improve visibility: Each stakeholder can check who has been assigned which work, who is idle, and for what reason?

4. Energy Management

You must know how and where you are losing money to control costs. The energy monitoring module of the MES software allows observing various energy sources like water, electricity, inert gases, steam, wastewater, etc. It also enables calculating cost per unit in real-time from meters installed across the facility. Moreover, MES software also allows manufacturing facilities to undertake critical sustainability initiatives such as 6 Sigma and Lean manufacturing by dealing with energy waste.

The features of the energy management module of the MES software are as follows:

- Capture and store critical data from PLCs automatically.

- Create reports based on numerous parameters like area, source, process, and equipment.

- Upload energy costs to appropriate cost centers in the ERP system automatically.

- Automatically sends alerts/notifications through email when the threshold exceeds.

- Record peak demand and search for new trends.

- Easy-to-use dashboards that show energy demand and consumption in a visual format.

The benefits of this module are:

- Respond smarter and faster: React to notifications and alarms at lightning-fast speeds.

- Enhance visibility: Getting complete data regarding energy consumption allows taking effective measures quickly.

- Reduce operational costs: Identify energy leaks and minimize energy waste while you aren’t actively producing.

- Control costs in a better way: Allocate energy costs across cost centers effectively.

<<<Also Read: ERP for Energy Industry>>>

5. Repairs Management

Equipment maintenance and breakdowns need to be prioritized efficiently and solved at the earliest. The repairs management module allows operators to capture the problem at the workplace in real-time. It also allows users to raise and prioritize work orders and track response times conveniently.

The features of the repairs management module of the MES software are mentioned below:

- Flag plant equipment, components, and machines that need repair.

- Assign repair work to engineers at the click of a button.

- Capture spare parts used and the person-hours required for solving an issue.

- Track results of each step in the manufacturing process simultaneously.

- Record repair time.

- Create and share work instructions with each stakeholder.

- View and assign repair requests automatically.

The benefits of this module are:

- Maintain electronic records: Improve mobility of maintenance teams using a mobile application instead of sharing manual updates.

- Enhance visibility: Each stakeholder can monitor the repair & maintenance status from anywhere and at any time.

- Create a single source of truth: Relevant stakeholders can access crucial business information from a single repository from anywhere and at any time.

- Improve accountability: Record repair and response times.

- Increase effectiveness: Get email alerts and mobile notifications, ensuring that non-core jobs aren’t missed.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.