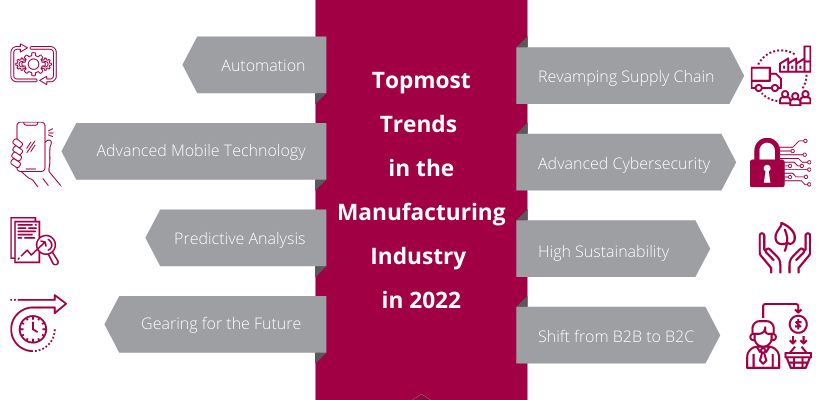

SUMMARY: 2021 has been a disruptive year for the manufacturing industry but it is going to bounce back in 2022. Since the covid-19 restrictions are easing and manufacturing activities are rebounding, the notable challenges remain the same including labor shortages, supply chain issues, inflation, and cybersecurity attacks. This article will shed light on the topmost manufacturing industry trends in 2022.

No doubt, 2021 has been a disruptive year for the manufacturing industry, and the coming year 2022 is definitely not going to slow down. Since the covid-19 restrictions are easing and manufacturing activities are rebounding, the important challenges remain the same including labor shortages, supply chain issues, as well as inflation. However, the recovery from the pandemic gained a fast pace in 2021 since the rollout of vaccinations.

The industrial production supplies capacity usage has elevated the pre-pandemic levels during mid of 2021. However, there might be a strong increase in new orders for different major sectors that are signaling continuing growth of manufacturing industries in 2021.

As the manufacturing leaders seek topmost solutions against disruptions and have been looking to strengthen their manufacturing business, we brought to you here the best trends that will shape the manufacturing industry in 2022.

Let us have a look at them.

Automating Manual Functions

The covid-19 pandemic has geared up the implementation of automation instead of manual tasks and processes. The pandemic has made manufacturing industry believe that they can leverage digital technologies to enhance their businesses.

Manual processes slow down the workflow of the business operations and it becomes very hard to manage everyday tasks with them. There are still a number of manufacturing companies that are using outdated systems due to which they could not see significant growth in the market.

But in the coming years, there will be a number of companies in the industry that will switch from manual systems to automated systems. The best benefit of an automated system is that it allows effective and agile operations that help make better business decisions.

Not only this but it also helps improve the overall quality control of the product while creating huge cost savings and delivering the desired product. Automation can be made possible with interactive robotic solutions through easy-to-use manufacturing process management systems and robot-human connections.

With the latest and advanced technologies in the industry, automation has given easy access to a number of manufacturers and is transforming the way companies have been operating. In short, automation for all would be the demanding platform in the manufacturing industry.

Speaking more clearly about automation in the manufacturing industry, industrial automation takes a very important role. With it, manufacturing businesses can attend greater accuracy and productivity. In the new generations, robotics in industrial automation is simple to program and easy to use, and possess the capacity to recognize image and voice to regenerate complicated human functions.

<<< Also Read: Top 6 Ways Furniture Manufacturing Industry Can Boost Productivity Using ERP Software With Enhanced Integration>>>

Improvised Mobile Technology

In today’s everyday business, mobile technology has become the most integrated part. However, in the coming days, we can expect various manufacturing industry to deploy mobile-friendly solutions at their workplaces. Since the manufacturing industry is continuing to evolve it is very important for professionals to adapt to the change and go with mobile technology.

The businesses that have already deployed the latest mobile technology into the workplaces have noticed numerous benefits. They are-

- Significant communication

- Developed efficacy

- Minimal errors

- Accurate connection of different teams

- Simple integration with accounting operations

Moreover, mobile technology has brought notable transformations in faster order and invoice processing operations.

Predictive Analysis

Today a number of manufacturing professionals are integrating business management systems into their workflows in order to gain best-in-class customer and competitor insights. However, manufacturers are also lettering predictive analytics to prepare well for the transforming future. With predictive analytics, manufacturers can get improvised access to real-time data while the industry will easily identify the changes in the inventory and can make respective decisions whenever planning for the projects in the coming time.

With predictive maintenance technology, they can automate the complete process of investigating and predicting the floors as well as problems occurring during the manufacturing process.

The excellent output of this analytics is-

- Low downtime

- Higher cost efficacy

No doubt predictive maintenance and analysis will prove to be a boon for manufacturing industries that can help meet customer demands and embrace the digital transformation.

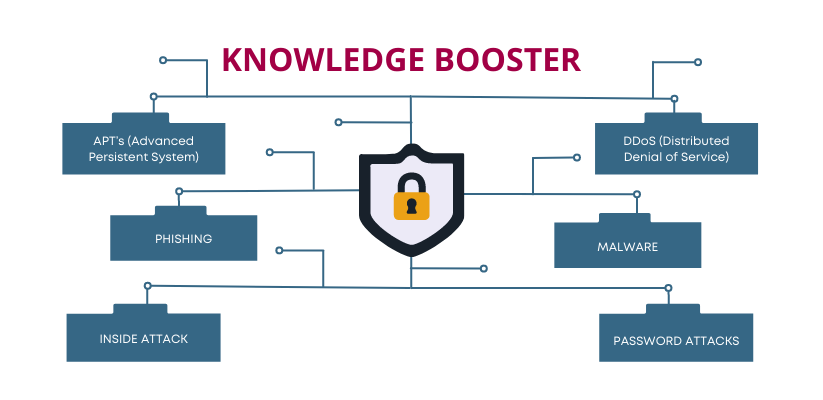

Developing High Cybersecurity

High-level cyber-attacks throughout industries in the recent past have escalated cyber security issues as a part of risk management to stop the increasing threads during the covid-19 pandemic has added to the business risk for manufacturing professionals.

Since the attack has been expanding from the sensitive connections of operational technology, external networks, and information technology are requiring advanced controls. However, legacy technology and systems proved to be a loss for the current network challenges. Also, remote work dangers are more prone to data breaches for manufacturing professionals.

To resolve these issues manufacturers should look for advanced cyber defenses but should also bring high-level flexibility to their business in the wake of cyberattacks. Cybercriminals have been causing huge damage to the intellectual property of the manufacturing business along with creating great financial losses through malware. In the case of critical infrastructures, they can also consolidate a regulation patchwork of various industries.

Gearing for Future Work

As per the recent reports recording huge and field jobs would likely limit the higher productivity of manufacturing businesses in 2022. In order to retain and employ talent in the business, manufacturers are required to make strategies including reskilling of employees and recasting their employment brand.

To meet the hiring requirements in 2022 manufacturers should make jobs more appealing and desirable. To achieve this they can-

- Engage with a brilliant talent acquisition system to reach skilled talent pools

- Easily compensate for the wave of different voluntary and retirement positions

What else could they do to gear up for the future would remain the question of primary concern. Broadly, manufacturers should keep a good balance between innovation culture and retention to reach desired goals. Since flexibility at the workplace is becoming more prevalent in the offices they should also search for ways to give more flexibility to their workers so that the workers will be retained and will be attracted as well.

However, manufacturers can also set up a discussion panel with the IT department in order to create a strategic plan that will help them access the required budget to set for the next 10 years and can assist your organization to establish an expanded workforce.

Revamping Supply Chain

At present, supply chain challenges are still critical and obviously, manufacturers are facing continuous obstructions causing huge costs and testing incapacities. They are dealing with distribution delays especially for international supply chain connections which are costing huge expenses. There is a shortage of containers as well as components which is why their cost has been increasing drastically.

Buying manager reports have become even more complicated and the increasing costs of raw materials along with freight and low deliveries have been the cause of major concerns globally. While these challenges are on the verge customer expectations are as high as ever which is why manufacturers should develop round-the-clock services to cope with them.

Also, the transportation challenges may continue in 2022 that will include driver shortages and various congestion at container ports. Since the demand is increasing for the supply, increased costs will more likely to pass on the customers.

However, having efficacious communication strategies can mitigate the supply chain disruption effects. Effective communication at workplaces makes sure that everyone is working on the same front and has the same goal.

To cope with increasing needs and higher costs, the supply chain in 2022 should be multi-level while digital networks, as well as data analytics, can help make powerful, flexible, and multilevel decisions at manufacturing workplaces.

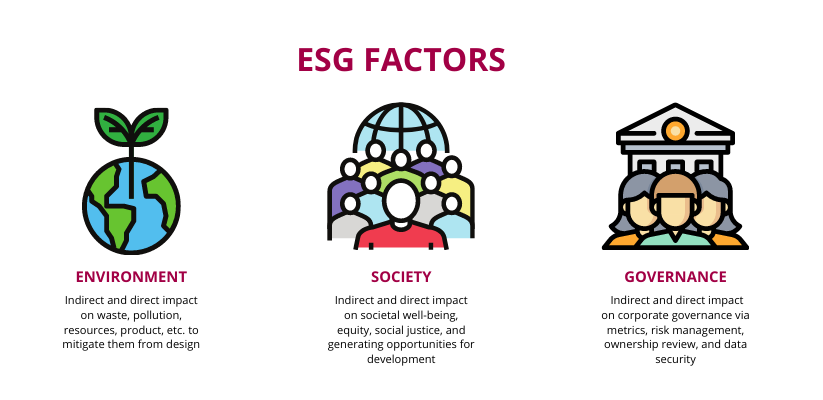

Advanced Sustainability

The rising demand for ESG (environmental, social, governance) factors is a sustainability concern in manufacturing and this could not be observed so strongly in the past. The total cost of capital can be shown as per the ratings on ESG while making it a high priority for manufacturing business financial health. Managing manufacturing industry operations in a completely sustainable and environmentally friendly manner is quite significant.

This is one of the most significant manufacturing industry trends to watch in the coming years. The cost of energy, as well as materials, have been rising and regulations have been tightened consumers, as well as investors, are gravitating towards sustainable brands as well as business practices. A number of manufacturers in the industry are already into creating environmentally and economically sustainable business practices for unprecedented growth in the manufacturing domain. They have also been focusing on developing and delivering carbon-neutral goals and are dedicated to getting quantifying efforts.

Since a number of manufacturers are connecting the equations between profits and sustainability this could be the most demanding trend of the manufacturing industry in 2022.

As per Gartner’s report, it has been estimated that by 2024, manufacturing businesses would often outperform their competitors by around 70% in satisfying their customers through ecosystem partnerships.

B2B to B2C Transformations

Manufacturing industry have been constantly transforming their focus on B2B to B2C due to numerous factors including higher margins, brand control, and more. Hence, it has become mandatory for them to enhance their operations to deliver quality customer services. Also, they should start supporting e-commerce businesses for varied business operations. However, among the highest priorities, secure payments, quick delivery, online customer services, and digital marketing will stay at the top.

Down The Line

So, these were the best manufacturing industry trends in the manufacturing industry in 2022.

To cope with the constantly changing market and customer demands, manufacturing businesses should focus more on retaining talented employees despite the declining labor force. In terms of efficacious supply chain management, the disruptions should go for workarounds through effective communication internally. In order to build higher flexibility, organizations should diversify the workforce since automation and robotics would become more prevalent.

Concluding on building eco-friendly manufacturing, professionals would be emphasizing achieving carbon neutrality. Also, businesses would make additional efforts to deliver continuous development and learning platforms to the workers while attracting and retaining them.

As per the Gartner predictions, around 20-25% of industrial manufacturers would be in support of EaaS (Equipment as a Service) along with IoT capabilities.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.