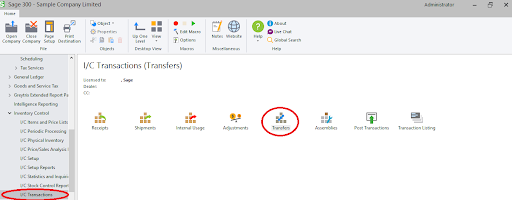

In this blog, we are going to discuss about “Inventory Control” Module and specifically about “I/C Transfers.” (can be accessed from I/C Transactions).

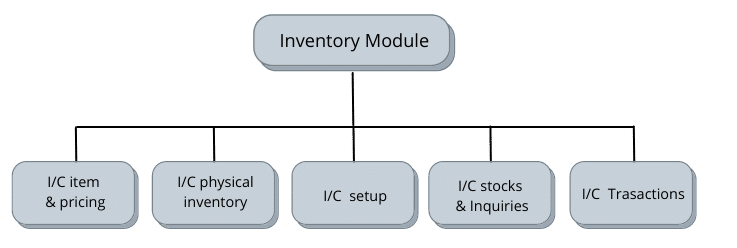

The Inventory Module has different type of sub-modules.

i)I/C items and pricing module is use to set the prices of the item, create new items

ii) I/C setup helps to set the functionality according to the choice of the user.

iii) I/C stocks and inquires basically generates report of the inventory present in the warehouse/location.

Use I/C Transfers screen to:

1) Enter and post stock transfers between physical inventory locations if you store items at more than one locations/warehouse. This will save the time and can help to improve the efficiency.

2)Sage 300 is so user friendly that a user can import transactions from other Sage 300 databases or from non-Sage 300 programs.

3) Import/Export transfer transactions from Sage 300 to Microsoft Excel.

4) Assigning Serial/Lot Numbers to Transfers, if you use Serialized Inventory and Lot Tracking.

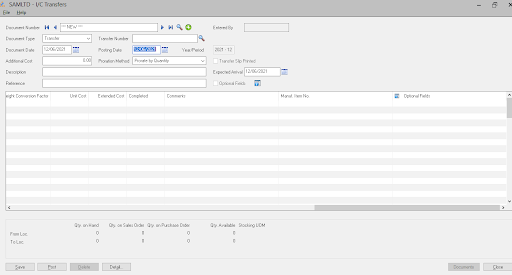

Here’s, how I/C transfer Screen looks like:

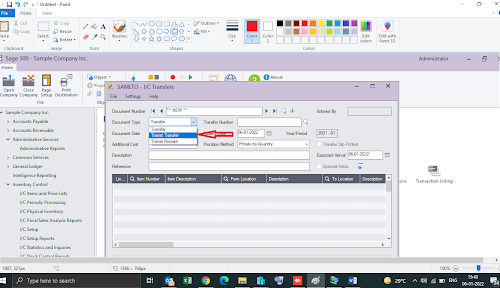

In this blog we are talking specifically about “Transit Transfer”.

Transit transfer is done by the sender; whereas transit receipt is done by the receiver

For example, if a company has two warehouses and they are transferring the goods form one location to another they will use “Transit Transfer” and once the goods are received at another location we will use “Transit Receipt”

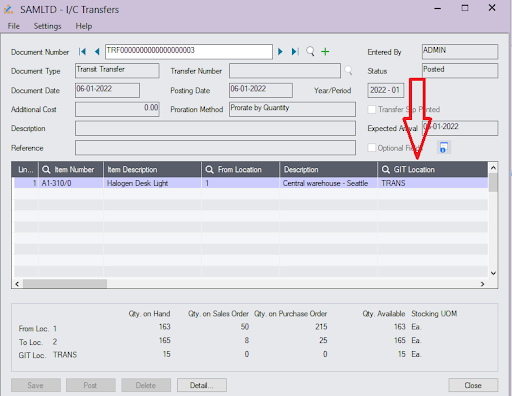

In between when the goods are being transferred from one location to another Sage 300 ERP has a feature where the goods are considered to be in Goods in Transit (GIT), because the goods are not at any of either warehouses.

Let us understand how Inventory flows in Sage 300 ERP. (For Transit transfer)

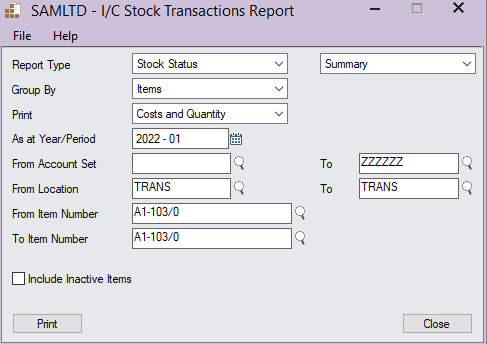

Sage 300 ERP also have a specific report for Goods in Transit, to know how much quantity we have in GIT, navigate to

Inventory Control 🡪 I/C Stock Control Report 🡪 Stock Transactions 🡪 Select Stock Status (Report type) 🡪 In Location select “TRANS”

{Fill the account set, location, item number asper your requirement}

With the help of this report an organization can identify the number of quantities that are still in Transit.