SUMMARY- Product recalls can create a greater level of disturbance in a company that also might create legal, financial, as well as, safety issues for a company. But, when product recalls are managed precisely they can help you in achieving appreciation for effective and decisive actions. The supply chain tips can help you manage a product recall effectively.

Product recalls can create a greater level of disturbance in a company that also might create legal, financial, as well as, safety issues for a company. But, when product recalls are managed precisely they can help you in achieving appreciation for effective and decisive actions. On the other hand, having a lack of knowledge to effectively manage a product recall might give long-lasting impressions on the reputation and finances of a company.

In this post, let us learn more about supply chain tips and about managing a product recall more efficiently and effectively while raising the reputation of your business.

Start the recall process

In order to manage a product recall, you should first initiate it since it occurs in response to a defect. Most of the causes of product recalls are related to safety. There also exist some product recalls that occurred due to some other reasons. For instance, let’s take the example of Intel corporation. In 1995 the company recalled approximately 1 million computer chips that had defects that generated errors in the calculation. This recall is known for the mismanaged product recall process.

So, Intel offered replacement chips only to those customers who proved that they were affected by the defect. Then after analyzing and discovering the defect, Intel became less vulnerable to the pressure and started a product recall.

Stay updated with product safety regulations

We all know that product safety rules & regulations are quite complicated and are different for different countries. They also keep changing often while becoming more stringent each time. If your manufacturing business is about to expand footprints in other countries, naturally, compliance-related rules would grow along with the complexity and likelihood of the product recall.

However, having an excellent central regulatory will establish better compliance with the existing regulations as well as the new ones. This way, irrespective of wherever you have been operating, you will remain on the right side of the law while managing product recall effectively.

These queries include checking faulty product batches along with facing the raw materials that were involved in the air process. You should also check if contamination is a new concern or it is being repeated for quite a long time.

By getting the latest data about the product, it becomes easy to check the core problem and you can address it with full confidence while providing market reassurance and alternating or mitigating the recall cost.

For easy and simple data access in real-time, you should store data at a central database from where you can track it through production operations as well as from the users. As per the regulator, it is expected that businesses should connect customers as well as ingredients via complicated and mica production functions.

However, if these processes are not being followed timely then it can cause a massive recall that could be too dangerous for a company.

<< Also Read: 6 inventory management tips for the food production industry>>

Stay totally transparent

Customers can fetch product issue reports as soon as somebody publishes them. A poorly managed product recall can be hazardous to the business reputation and sometimes it may cause irreparable loss. Hence you should control the process. The excellent way to overcome this issue is to place flawless communication with approval that the situation is completely in control and you have the appropriate solutions to deploy.

So in order to not lose customers’ trust, it is highly recommended that you should not make any statements for which you are not completely sure, especially when there is the pressure during the product recall process. Hence it is very critical for your business to have sturdy visibility and transparency of the supply chain since it authenticates the potential level of concern while quickly rectifying the cause. It helps to protect the reputation on a broader aspect.

Take decisive actions

If your business finally recalls every product and repairs the defect via a warranty platform then your business should act decisively while penning down the decision to avoid the negative effect of product recalls.

Also, you should check the advantages and disadvantages of product recalls in order to take decisive action. Product recall risks my deal with different issues such as cost, financial effect, and negative publicity.

But on the other hand, there are major benefits of a product recall that includes reduced risk and optimistic publicity that can help highlight your business commitment.

Also using the right tools to manage product recall proves to be an effective decision. There are particular extensions as well as solutions that are offered by the top ERP software. Use them and get accurate results.

<< Also Read: The secret sauce for effective food traceability – Food & Beverage ERP>>

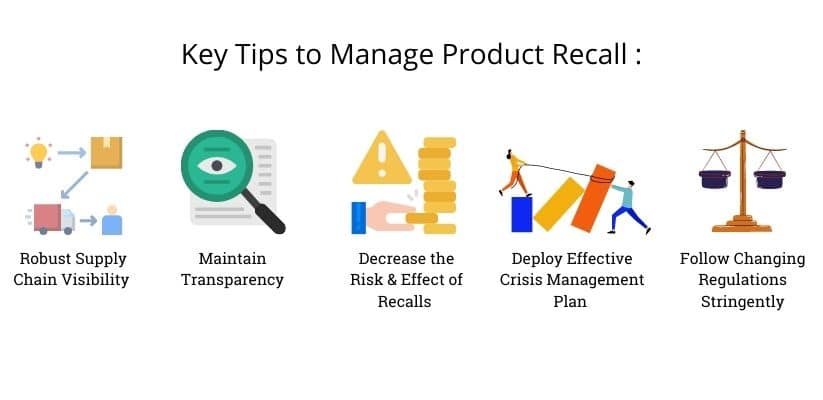

Minimize the risk and impact of a product recall

It is perfectly said that prevention is always better than cure and it is impossible to eradicate the chance of product recall. However, there are a few steps that can help you reduce its occurrence while mitigating the consequences-

Let us have a look at the important steps-

- Arrange mock product recalls

- To test for any defects take some samples from product batches

- Maintain flawless communication with every person in the supply chain department

- Constantly rectify and enhance supply chain functions to reduce risk

- Check customer feedback constantly including social media platforms through which you can identify the defects instantly

- Manage a completely dedicated crisis management team for outstanding results

- Minimize batch quantities in order to make it easy to give faulty products aside

Get a proactive crisis management plan

Time plays a crucial role in food and beverage product safety. It is highly advised to get a predetermined crisis management plan in order to make sure you are thoroughly crisis-ready. Inaccurate food and beverage crisis management plan includes some vital functions such as-

- Checking the severity of the risk

- Rectifying the level of contamination while isolating affected batches of the products

- Send notification to the distributors as well as retailers as soon as possible about the product defect

- Deploy stringent product recalls procedures in action

- Publish transparent data to customers on the product recall

- Reporting the product concerns to the respective authority team

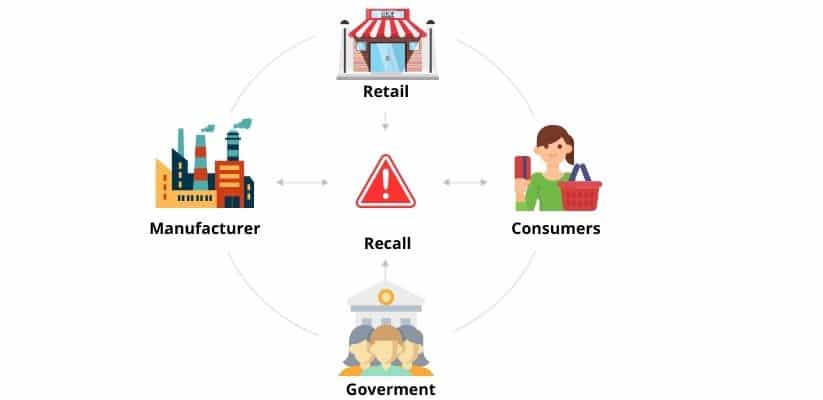

Secure chain of command

Product recalls mean your businesss’ reputation is obviously at risk and hence to protect the total integrity of the brand, different retailers as well as manufacturers should ensure that the customers confronting communication should put the brand in a positive way.

Hence, it is quite important to manage the topmost quality standards as well as a document through every step of this process which might deal with transporting as well as storing products with a secure chain of command. It might also deal with managing product testing as well as product recalls with respect to regulatory compliance.

Improve effectiveness

Usually, product recalls occur without any warning and hence it becomes tough for businesses to get prepared in advance. Through a complicated supply and distributed change, it might be very difficult financially to get full-time team members that can manage a product recall while putting the internal resources into the procedure.

But you should remember that this may cause hazardous for your business since shifting your current staff from their normal work might interrupt the routine business operations which can apparently delay the retrieval process of the product and will surely cause high expense. Hence, getting a third-party solution provider who can help emphasize retrievals would be the best option and the most effective method of deploying a product record.

<< Also Read: Meet chemical regulations through integrated traceability data>>

Proper documentation

One of the best supply chain tips is to have proper documentation. Whenever it comes to shifting complex relations it becomes quite important to oo take care of all products while maintaining their integrity of them for additional analysis as well as testing. This clearly indicates that the product of the journey should be accurately documented not just for any legal issues but also to maintain customer trust in the brand.

Proper documentation requires greater attention to reverse logistics and you need a stringent chain of custody that can help you document execute as well as complete the returnable event in a systematic manner. Since it is highly advisable that companies should not forget about documenting the entire product recall process.

With these ingenious supply chain tips, you can effectively manage product recall and maintain the reputation of your business!

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.