Summary:

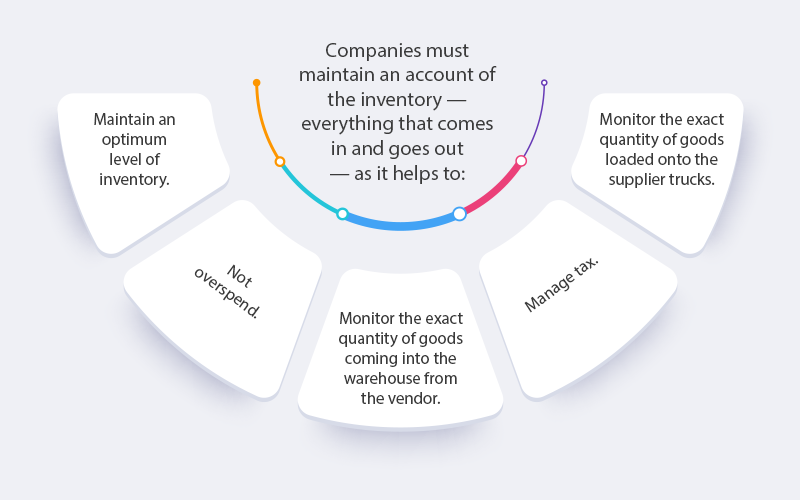

Discrete manufacturers must purchase and manage inventory responsibly. By having a dedicated manager looking after the inventory, you can monitor what materials are stored in the warehouse, what is being moved on to the service trucks, and the number of raw materials required to maintain an optimum inventory level.

Discrete manufacturers produce finished goods like toys, smartphones, automobiles, airplanes, or other tangible products that consumers use in everyday life.

But many discrete manufacturers don’t have a dedicated inventory manager and inventory management software that impacts customer relations and decreases profitability.

Customers don’t prefer dealing with companies that delay projects because of the lack of required materials or because they are unaware of the tools and equipment they have in the inventory management.

Some companies use manual spreadsheets to maintain records, which is a time-consuming process and leads to human-induced errors. The worst part is that some companies aren’t tracking their inventory at all.

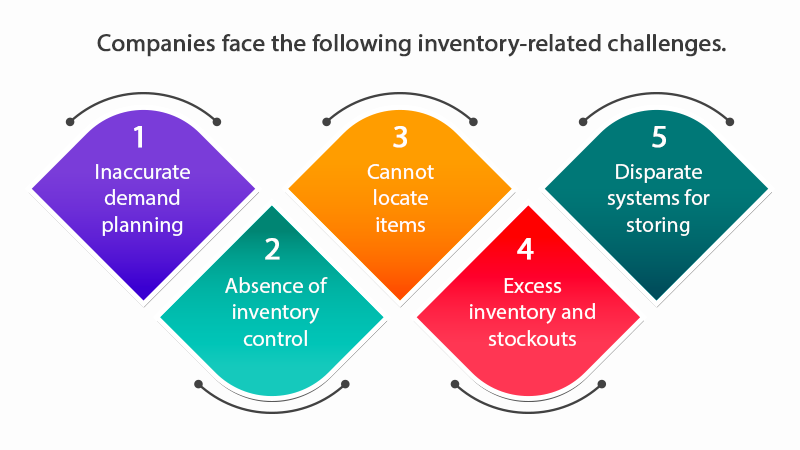

1. Inaccurate demand planning.

It’s challenging to predict the optimal quantity of materials and equipment you may require in the future if you don’t have records to analyze how much you have used in the past.

2. Absence of inventory control

Without an efficient inventory control process to monitor what is coming in and going out of the inventory and the location of items in the warehouse, it’s difficult to predict future needs.

3. Cannot locate items

The required item is often present in the inventory, but it’s challenging to locate their exact location. This may happen because of two reasons:

a. Absence of a designated storage location.

b. Multiple storage locations for the same item.

4. Excess inventory and stockouts

Remember that inventory is a liability in the balance sheet. So if you have more than the required inventory, you are making net losses. Numerous companies purchase excess inventory that sits on the shelf without being actively used in any project. As a result, a lot of cash is tied up that could have been used to carry out other productive projects.

On the other hand, sometimes companies suffer from stockouts where they don’t have the minimum level of inventory required to carry out daily operations. It leads to emergency purchases and delays in delivering products to the end-user, which might deteriorate the customer experience.

5. Disparate systems for storing accounting and inventory details

A substantial amount of companies store accounting and inventory-related details in different systems. It has several demerits like unnecessary manual work, increased human-induced errors, and a mismatch in data. Another thing to consider is that the inventory levels are constantly fluctuating, which means that manually maintained inventory records will be inaccurate.

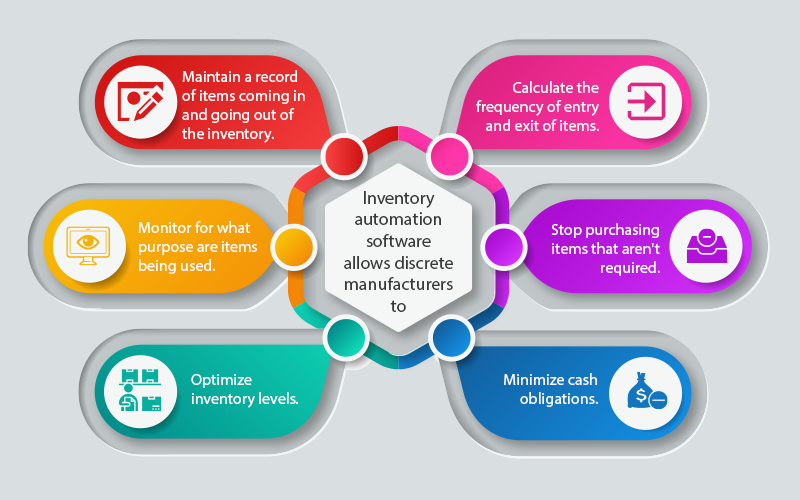

Here’s how inventory management software will help you:

1. Improve inventory visibility

You will gain significant control over critical parameters like average lead time, the exact location of inventory in the warehouse, historical purchasing patterns, managing reorders, and maintaining optimal inventory management levels.

2. Enhance inventory control

You can monitor and manage the entire inventory lifecycle and control costs. Moreover, the software tracks inventory usage and sends notifications to dedicated managers if the inventory levels go below the set threshold.

3. Accurate system of records

All the information — location, production date, expiry date, cost, lot number, and quantity — about each item, equipment, and material is safely stored inside secure servers accessible to relevant stakeholders from any place and any time. Also, information is updated instantly in real-time, eliminating errors, and saves employees’ time who can focus more on mission-critical tasks.

4. Creating accounting efficiencies

Disparate information systems are the root cause of organizational inefficiency. Inventory management software bridges the gap between different ERP systems and updates data in real-time, which helps to maintain error-free records.

5. No excess inventory and stockouts

Real-time inventory information will allow you to purchase only so much inventory that can be used actively to carry out daily operations. First, in this way, you can save a lot of money that would have otherwise been spent on purchasing unwanted tools and equipment. And secondly, you will never face stockouts because you will always have a minimum inventory management level to execute productive projects.

Conclusion

Maintaining an adequate level of inventory is essential for business across all sectors. It helps you save costs, boost profit, and have emergency stocks. Inventory management software provides these benefits to discrete manufacturers to retain their market competence and provide an excellent customer experience.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.