What is ABC analysis?

Every item in the inventory doesn’t have an equal value. To analyse the value of each item in the inventory, ABC analysis is the right technique. It is one of the most significant techniques of inventory management used to determine the items that give the utmost worth to the business. It is also known as the ABC classification or selective inventory control(SIC). In this technique, items are categorized based on high demand, medium demand and risky.

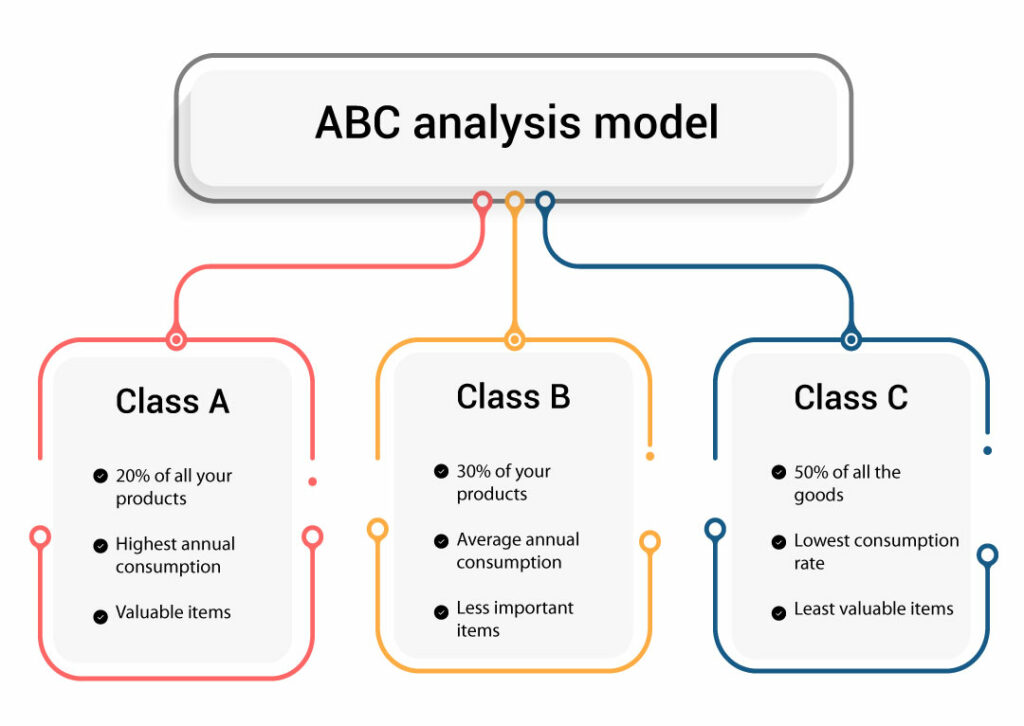

In simpler terms, the ABC classes items into A, B and C categories based on the value it gives the business. The items are segmented depending on the sales volume or profitability. Category A will have the highest value, category B will have the next important and Category C keeps the least valuable item. This will give businesses the data of the item that is giving maximum value and the list of items that is giving low value.

ABC inventory analysis is vital for the business to prioritize and optimise inventory to make insightful decisions for the business. Some companies will group their products into more groups(A-F).

How to perform ABC analysis?

To measure inventory, companies must follow certain steps.

Step 1: Multiply the price of the item and the consumption period during a certain period.

Inventory value = Item price * Consumption value

Step 2: Classify the inventory items from the highest to the lowest.

Step 3: Calculate the contributing value of each item in the percentage of the total inventory value.

Item % of the total inventory value = Item inventory value/ Total inventory values

Step 4: In the final step, add items based on the contribution to their entire inventory value. For example group them into categories A, B and C.

Example of ABC analysis

For example, a business is involved in the selling of backpacks in retail and the owner decides to expand by launching snow boots. Later the owner purchased 20 different backpacks instead of 8. And the owner realises that the demand for the product is only seasonal.

So he uses the ABC analysis to categorise the inventory into A, B and C groups based on the demand and the value.

Category A: The best-selling backpacks that are high in demand and generating maximum revenue are added to this category. And if snow boots are trending in the current season, add them to this group.

Category B: In this group, the backpacks that are selling well but not as much as A is added. And if their demand is moderately seasonal, it will remain in this category till the sales shoot up.

Category C: The goods which do not give the expected value are included in this category.

Also Read : What is FSN analysis in Inventory Management?

What are the benefits of ABC analysis?

Inventory control is a major part of the supply chain management system. ABC analysis is one of the effective inventory management methods. It will give clear data on the number of units sold, customer demand, annual consumption value and obsolete inventory. Let’s discuss its multiple benefits on how it lowers inventory inefficiencies.

ABC method helps in reducing inventory cost as each item is organised.

Organise and optimise inventory

ABC inventory is a well-managed inventory that helps businesses to clearly understand the products that are high performing and the products which are not up to expectations. And all these products are adequately stocked in the A, B and C categories.

Better inventory forecasting

Monitoring, establishing better inventory control and accurate inventory data will help in creating precise sales forecasts. These insights are used by the executives to prepare strategies, set inventory levels and fix costs to maximize revenue for the company.

Improves pricing

ABC inventory management technique helps in increasing the pricing of best-selling products reasonably. Suppose there is increased demand and sales for a particular product, gradually the price can be thoughtfully increased.

Supplier negotiations can be enhanced

If the company is sure about its high-value class A inventory items, it can come to better terms with the supplier regarding the pricing of raw materials. If the supplier isn’t ready to lower the price, convince them to provide a post-purchase service or reduction in the down payment or free shipping.

Accurate demand forecasting

ABC analysis technique can clearly inform the inventory planners about the demand for the product with the right data obtained from inventory optimization. It improves supply chain management effectively by minimising the carrying costs of obsolete goods.

Better allocation of resources

ABC analysis is a better strategy to allocate resources. The items should be frequently sorted and allocated based on the demand in each period. So if demand for a particular product lowers, it has to be reclassified and space for best-selling goods during that season should be given under class A.

Efficiently manage the product life cycle

Better insights can be obtained regarding the product life ( launch, progress, maturity or reduction). These insights are crucial for demand forecasting and accurate stock management resources in the inventory.

Improved customer support

Abc analysis can help in determining to provide better after-sales service to the products which are of high value and best selling. Service can be measured based on different parameters such as quantities sold, cost of the product and its revenue margins.

Lowers inventory storage expenses

ABC analysis for inventory management helps in maintaining the right proportion to lower inventory carrying costs.

Manage Supply Chain system seamlessly

ABC analysis for inventory control helps in making decisions about whether it’s the right time to consolidate suppliers or to move to a centralised base to lower carrying costs and ease operations. Inventory records help to understand demand and supply which contribute in the efficient function of the supply chain process.

Better control of high-priced goods

The Category A inventory is healthy for the company’s growth. With the data from the inventory and monitoring market demand for high-value goods, maintain a balanced inventory.

Disadvantages of ABC analysis

ABC analysis has multiple benefits to offer for accurate inventory management. Yet there are disadvantages to this technique. Let’s discuss a few here.

Regularly organize goods

Frequent ABC inventory analysis must be done to assess if the class A items are still on the high-priority list. If not, the resources will be wasted on these goods. If you don’t have good technology, data collection and inventory assessment will put a strain on the business.

No ample information

ABC analysis may generate inventory inefficiencies if it doesn’t extract accurate data or provide statistical information to take better strategic decisions.

Overstocking or stockouts issues

After putting more focus on high-priority goods, there is a chance that the low-value goods will run out of stock. Sometimes the low-order goods will exceed if the employee won’t review them continuously.

Risk of loss

Low-value goods should also be prioritized. Or if the goods are not monitored from time to time, they may be subjected to theft which will result in a loss for the company.

Works only if the goods are standardized

ABC analysis works only if the items are standardized, like on what basis it is named, stored and constantly rated and monitored.

Pareto principle

The Pareto principle is also known as the 80/20 rule. And ABC analysis is based on this principle. The rule means that the top 20% of the items represent 80% of the sales volume.

So the class A items are lesser in comparison to class B in which the items are a little higher and C goods have the majority of items.

It is stated that the Pareto principle is accurate but analysis shows that it is possible for the valuable items to bend towards an 80/20 distribution.

ABC analysis- Best practices

ABC analysis is the best practice to control inventory. Technology is one of the best remedies to have end-to-end management of the inventory as it needs to be consistently monitored and reviewed.

Here are some of the best practices to apply abc analysis technique effectively.

Classify the inventory in a simplified manner

Group the products depending on how quickly it moves out of the enterprise. Classify them into three categories based on their value or profit margin. Group A includes expensive items, group B involves average-priced goods and Category C has the lowest consumption value goods.

Entrust labour simultaneously for each categories task

The service levels should be assigned based on the class the item belongs. Category A has the highest target and at the last category C has the lowest target.

For example, assign employees to review 100 goods for 10 hours for the items whose annual consumption value is high and at the same time, assign employees for 10 hours to review 10,000 goods for the low-value items.

Category-wise set KPIs

Create KPIs for each category, separate dashboards for each and corresponding reports. Such accurate records can support good sales forecasting.

Conduct performance reviews

Review inventory during maintenance and check how it is performing after applying abc analysis technique.

Manage and maintain multi-segmented inventory

Most enterprises have many stock-keeping units(SKUs), so supply chain executives need to efficiently manage these across different locations. A good warehouse management software like an ERP system can help to manage multi-segmented inventory better.

Measure inventory even during transit

Sometimes stocks have to be moved in between locations. When that happens, ensure that you track the number of units, stock levels and time between the shipment date and the receipt date. All this information keeps inventory in order and make sure to record any damage or loss incurred.

Consider sales and inventory in conjunction

Sales and inventory go hand in hand. As the sales increase, the inventory also should be assessed and restocked. Suppose there is a downturn in the market, the item classes have to be evaluated again, and the promotional strategies and pricing have to be assessed.

Leverage the benefits of technology to conduct ABC analysis effectively

Employees in charge of the inventory can use an automated technology like an ERP system to apply and manage ABC analysis efficiently. It can recognize trends in the market, solve fulfilment issues, and leverage data to manage basic demand patterns and lead times.

Application of ABC analysis across industries

The ABC analysis technique is implemented across industries as it is an effective inventory categorization method. Let’s learn more about how ABC analysis and the 80/20 rule is applied in a different industry.

Automotive industry

In this sector, abc analysis introspects the efficiency of line workers, information about resource employment, and identifying the highest performing equipment. Optimized inventory will give insights about raw materials and helps in negotiating with suppliers.

Manufacturing

ABC analysis for the manufacturing sector is applied by segregating 20% of goods by dividing it based on revenue, it will help the industry to increase profit margins.

Retail

ABC analysis enables retailers to identify the items that are more profitable to the business. Later this data can be used for promoting the item across retail locations and to keep adequate stock levels in the inventory.

Warehousing

ABC analysis is applied to establish control and manage high-value inventory. It is vital to manage the right amount of stocks to prevent any stockouts.

Also read : 10 Inventory Management Trends to Watch for in 2023

How to implement ABC inventory management?

First research and assess if the ABC analysis technique is suitable to manage the inventory of your business. Eliminate assumptions and make decisions based on your current inventory insights. For smoother execution, make the required preparations.

Prepare a set of questionnaires regarding inventory control and assess if the technique can be deployed for your inventory. Find out the goal of executing this technique for your business. Decide on proceeding only if it is suitable for the inventory or else it will cost your business and consume a lot of time.

Conclusion

ABC analysis is a crucial inventory management tool which helps the business in identifying the most valuable products of the business. By grouping the items into three categories based on value, businesses can optimise inventory, reduce costs and maximize profits. The Pareto principle’s 80/20 idea is the key point of ABC analysis. Through this analysis, companies can spend most of their resources on high-value items.

This technique is highly worthwhile to invest in businesses with a large inventory to establish control and efficiency. Use ABC analysis technique and manage your inventory item efficiently.