Summary: The ERP in manufacturing industry revolves around the production, process, and preparation of raw materials into a finished product. According to a recent study, capacity utilization in India’s manufacturing sector stood at 72% in the second quarter of FY22, indicating a significant recovery in that sector. Some of the challenges faced in the manufacturing industry are distribution, finance, cybersecurity, supply chain management and many more. Advanced ERP software helps overcome manufacturing challenges and automates manual and repetitive manufacturing operations.

ERP or Enterprise resource planning has various features, including production, business intelligence, inventory & warehousing, quality control, finance & accounting, vendor relationship, and much more.

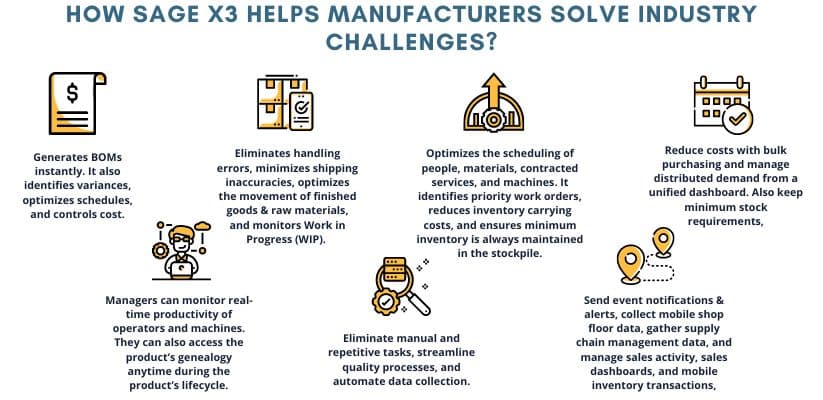

It assists the users to plan, manage, and execute manufacturing business operations, helping in:

- Cutting operational costs.

- Eliminating redundancy.

- Generating Bills of Materials (BOMs).

- Identifying obsolete machines with reduced efficiency.

- Automating shop floor control.

- Efficient quality control.

- Quick product recall.

Collecting real-time data from multiple sources and updating them across disparate data systems simultaneously is another crucial feature of ERP in manufacturing.

It saves employees’ time allowing them to focus on mission-critical tasks instead of performing repetitive functions that give rise to human-induced errors.

ERP in manufacturing is the backbone of a large-scale industry managing all intricate business functions efficiently.

Pain points of the Manufacturing Industry

A manufacturing company is filled with challenges like integrating disparate information systems spread across different departments, collaborating with vendors, suppliers, and distributors, real-time monitoring of inventory, reducing machine downtime, forecasting products customers are most likely to buy, and forging robust customer relationships.

1. Supply Chain disruption

- Increasing the cost of raw materials can impact the supply chain.

- Absence of end-to-end data transparency.

- Shortage of raw materials.

- Drop in product demand.

- Insufficient inventory data.

Here’s a comprehensive account of the challenges in each department:

2. Finance and Accounting

- An accounting executive faces challenges while tracking, planning and budgeting the financial data to reduce unprecedented expenses and maintain suitable profit margins.

- Maintaining multiple ledgers gives rise to human-induced errors and wastes employees’ time that they could have used for brainstorming strategies and achieving mission-critical tasks.

- Monitor cash flow — Calculating accounts payable and accounts receivable manually is a challenge. Sending emails and notifications to vendors who don’t pay on time and sharing reminders with the finance & accounting team to pay distributors on time is difficult if done manually.

- Estimating a competitive price for your product based on average market cost is challenging. It can reduce your gross profit margins in the long term.

- Better inventory management allows companies to maintain an appropriate quantity of raw materials in the inventory. Employees might find it challenging to monitor inventory in real-time, leading to stockouts or surplus stocks that drain a company’s profit.

Moreover, if done manually, identifying vendors that provide discounts and deliver products on time might take plenty of time.

- Next, plan to keep indirect expenses like people, utilities, rent, supplies and insurance at the minimum. Check if the purchased machinery and warehouse space are optimally utilised. Moreover, you can sell dysfunctional machines to reduce maintenance costs.

- The advanced business intelligence module allows decision makers to take the right financial decisions — cut operational costs and earn better profits — based on changing market conditions and customer preferences.

3. Shipping and logistics

Shipping and logistics are a significant part of the supply chain.

- Monitoring the inventory.

- Distribution of stored goods to the destination.

- Reversed logistics – Customer returning the goods to the supplier.

- Transportation of goods to the warehouses.

- Manage proper packaging of goods.

- Handling the product with care till it reaches the location.

4. Monitoring systems ineffective

In manufacturing companies, there are a lot of critical business functions that need to be tracked. Operations like distribution, finance, production, front-to-back office management and customer relationship management are to be checked to maintain workflow.

Automation is the key to managing all these crucial functions. Installing an ERP system helps integrate all the operations into a single database.

5. Frequently changing regulations

Manufacturing companies must be aware of the changes in regulations imposed on versatile industries.

In India, FSSAI(Food Safety and Standards Authority of India), ASCI( Advertising standards council of India), Pharmacy Council of India and many more are examples of regulatory bodies.

<<<Also read: ERP for Manufacturing Industry in India>>>

The Significance of Enterprise resource planning ERP for Manufacturing industries

1. Inventory management

- An ERP system gives accurate data on the quantity of the stocks left in the inventory. If the stocks are less, the software will send a reminder to the executive in charge of the inventory.

- ERP software gives precise data on product status, finished products and purchase order tracking.

- Track the amount of raw materials used for the production process to reduce wastage. Sometimes the use of excessive raw materials can affect profit margin.

- Monitor all the operations of the inventory.

- Aids in exact Materials Requirement Planning(MRP).

2. Compliance and risk management

- The information stored in an ERP software database is highly secure.

- ERP system gives updates on the changes in the regulatory standards by sending alert notifications.

- ERP software ensures that manufacturing companies adhere to human resource regulations.

3. Quality Control

ERP system ensures that the manufactured product meets the highest quality standards by tracking and monitoring its development throughout its manufacturing stages.

The quality of the product is improved by continuous testing and examination. All the data are later registered in the ERP database.

4. Process Automation

ERP in manufacturing is a highly automated software that integrates sales, purchases, records, stock and human resources processes.

Automation saves time, and executives can focus on more value-added tasks. The users can access real-time data to monitor and control business operations.

5. Raw materials Management

- Manufacturing ERP software aids in tracking raw materials to prevent wastage.

- ERP system helps in planning to reduce excessive wastage to lower production costs.

6. Financial Accounting

Manufacturing ERP systems manage the business functions from the top floor to the shop floor. The finance and accounting module is a significant function of the company.

ERP in manufacturing maintains an accurate record of the financial reports helping the senior management make the right business decisions in the future.

7. Access to data to improve Customer Service

An ERP system allows continuous distribution of information accessible to all the internal teams. The coordination of front office to warehouse management is a crucial aspect of ERP in manufacturing industries.

Real-time information is accessible even for non-IT users helping them to have accurate data to answer all customer-asked queries. Better customer service helps a business to grow.

8. Supply Chain and distribution

Enterprise resource planning (ERP) is vital in the supply and distribution module. Accurate on-premise data on packages, warehousing, logistics, point of sales, vendors and suppliers are recorded in an ERP software database.

Continuous flow in the supply chain function enhances the production of goods for manufacturing industries. Let’s look at the benefits of ERP for supply chain and distribution modules.

- Faster delivery of the product to the customer.

- Enhance productivity.

- Monitor inventory control.

- Navigate product location.

- Well-organised shipping operations.

<<<Lets study in detail: How can Manufacturing ERP help businesses function smoothly?>>>

Types of ERP in Manufacturing

There are three types of ERP in manufacturing industries. Let’s learn more about these types.

Cloud ERP

- Cloud or SaaS services are delivered via an offsite cloud system.

- It can be accessed via a desktop or a browser.

- Cloud solutions are subscription based. Monthly plans or annual plans are the payment modes.

- Data and configuration are done by the vendors providing the services.

On-premise ERP

An on-premise manufacturing ERP system can be accessed only in an office location or any specific business location. It is an all-in-house software that can be accessed only by executives in the company. The data is stored in a private cloud system without any cyber security risks. The updates and the application is managed by the company.

Hybrid ERP systems

- Hybrid ERP is also known as a two-tier ERP system.

- It is a combination of cloud ERP systems and an on-premise ERP system.

- The sensitive workload can be stored in the private cloud and general data can be stored in the public cloud.

ERP in manufacturing industries is essential to manage all business processes. An industry is an intricate sector with multiple business functions. It has to be managed efficiently without any confusion or blockage. Plus, it is a rat race among industries to stay on top. ERP in manufacturing is the solution for monitoring and controlling this huge business effectively. Investing in top manufacturing ERP systems will assuredly increase profit margins.

About 88% of the companies succeeded in managing their business upon ERP software implementation. Undoubtedly ERP in manufacturing solutions is the best software to leverage the company’s growth for manufacturing companies.