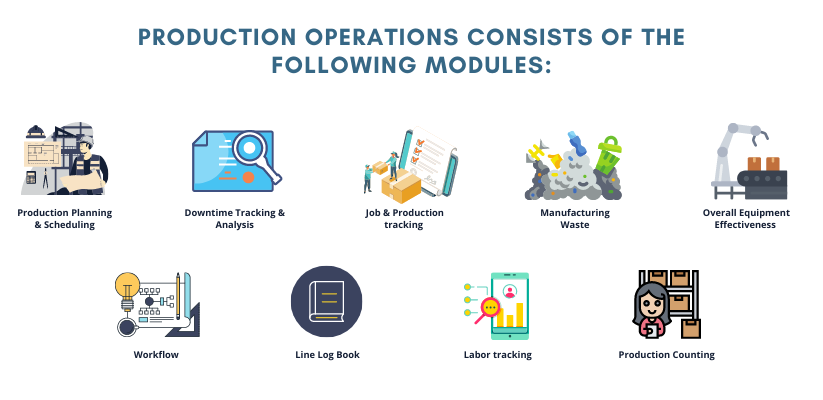

Summary: Production operations constitute the majority of manufacturing activities. It comprises planning & scheduling, tracking downtime, counting production units, recording manufacturing waste, calculating equipment effectiveness, enhancing communication between various teams, calculating wages by recording labor hours and monitoring the production activities’ sequence. MES software has 9 modules that play a critical role in managing production operations.

MES software can be divided into four areas, namely Production, Inventory & Logistics, Quality, and Maintenance operations. In this blog, we will discuss everything about the production operations in the MES software.

1. Production Planning & Scheduling

The production scheduling software allows users to visualize their plans in real-time, optimizing their capacity and resources accurately. The best part is that you can minimize (or eliminate) your dependency on spreadsheets.

This module of the MES software will help you:

- Share the production schedule with employees on the shop floor immediately.

- Create production orders manually or download them from the ERP system automatically.

- Receive real-time updates and feedback on the production schedule.

- Track tool handovers, machine changeovers, and material changes conveniently.

- Eliminate your dependence on a complicated and heavy capacity scheduling system.

- Recognize your ability to meet deadlines and get a 360-degree picture of your manufacturing capacity.

- Generate a sequence of the production orders that are going to be executed on the production line.

- Schedule the end and start dates of order quantity and cycle time based on master data.

The benefits of the Production Planning & Scheduling module are as follows:

- React smarter and faster: The plan is updated in real-time if the production line runs slow or stops.

- Communicate effectively: Exchange of critical business data between the production team and the planners is considerably improved.

- Become more agile: Significantly improve your ability to respond to unplanned events.

- Delivery management: Get 360-degree visibility about delivery dates.

- Get instant feedback: Receive real-time updates about the production plan — how much has been achieved and how much is yet to be achieved.

- Manage resources more effectively: Optimize resources and work at your full capacity.

>>>Also Read: 5 must-have components of Advanced Planning and Scheduling software<<<

2. Downtime Tracking & Analysis

Machine downtime is a significant challenge for many manufacturers as it limits their ability to reach their maximum capacity. Moreover, most companies use a pen and paper system to record all downtime events, making it challenging to examine the problem and improve.

This module of the MES software will help you:

- Monitor and track stoppages where there are no machine connections.

- Make improvements by critically examining equipment downtime and downtime losses.

- Automatically record downtime reason codes and start and stop events.

- Identify stops and decrease your response time dramatically.

- Record stoppage duration.

- Collect, analyze, and store data inside a single repository that acts as a single source of truth for all relevant stakeholders.

- Thanks to its dual mode of operation, you can gather some data automatically and the rest manually.

The benefits of the Downtime Tracking & Analysis module are as follows:

- React faster and smarter: Get your production process running at full speed after experiencing downtime.

- Reveals insights: Revealing the hidden costs related to short stops.

- Increases visibility: Access live dashboards that provide real-time data about machine downtime.

- Minimize losses: Take improvement decisions based on real-time data.

- Create a detailed account for downtime history: Identify loss-making machines that waste resources and don’t work at their full capacity.

- Eliminate downtime losses: Downtime has a considerable impact on the Overall Equipment Effectiveness. By making tiny improvements in the up-time, you can substantially improve your bottom line.

3. Job & Production tracking

This module will help you transition to a paperless system and significantly improve work order progress visibility.

Other features of this module of the MES software include:

- Monitors the progress of the routing process.

- Tracks and records the beginning and end of each production run

- Keeps track of the sign-offs across each production stage.

- Stores the history of each production order in a single repository.

- Monitors and tracks the progress of each production order across the factory.

- Shares the progress report with the ERP system that relevant stakeholders can access at any time and from any place.

The benefits of the Job & Production tracking are written below:

- Go paperless: Save data electronically instead of hand-written records that are prone to theft and manipulation. Also, reduce your operational cost by discarding the use of pen and paper.

- Enhanced traceability: Track varying parameters regarding different production orders such as materials consumed, quality checks, lots created, and much more.

- Real-time work status: Get real-time work order status about each production order running throughout the factory.

4. Manufacturing Waste

Scrap and rework can negatively impact a company’s energy and resource utilization, production capacity, and manufacturing processes.

The manufacturing waste module of the MES software will enable you to:

- Examine the waste produced across each production run, process, shift, and product.

- Monitor the in-line and end-of-line manufacturing waste.

- Track the waste, scrap, and spoilage across every stage of the production process.

- Assign user-defined reasons for rework that can be tailored across each production stage.

- Examine manufacturing waste trends on a daily, weekly, monthly, semi-annually, and annual basis.

- Capture crucial KPIs like First Time Through Quality (FTTQ) and First Pass Yield (also known as Quality Rate)

- Trigger alarms and automatically send emails and notifications to concerned authorities.

- Critically examine manufacturing waste based on various parameters — department, process, crew, shift, reason, machine, and product.

The benefits of the manufacturing waste module are mentioned below:

- All-round effectiveness: Minimize the operator’s time by tracking the shop floor data.

- React quickly and effectively: Access a broad range of visualization tools to solve issues rapidly.

- Minimize scrap and rework: Bring down losses in production capacity, including workforce, energy, and material utilization.

- Improve continuously: Strengthen first pass yield and support lean management.

>>>Also Read: ERP for waste management firms<<<

5. Line Log Book

Many businesses still rely on paper-line logbooks for storing crucial business data. However, the major disadvantage of using them is that they give rise to information silos, which impede the free flow of data between different teams.

The line books module of the MES software will allow you to:

- Adopt an electronic way of storing data and ditching the more unreliable and time-consuming pen and paper system.

- Generate shift records by tracking all the processes and functions and distributing them to relevant stakeholders.

- Records each shift event, including tool changes, set up conditions, process adjustments, and material changes.

- Improve inter-department communication and enhance visibility across all processes.

- Each data point is time-stamped and related to the manufactured product, production run, equipment, and process.

The benefits of the Line Log Book module are written below:

- Eliminate mistakes: Access the logbook anytime to sift through all the recorded issues and examine their cause.

- Track issues faster: Trace issues more quickly across all shifts in the production record.

- Bring down operational costs: File and handle paper records in an inexpensive way.

- Gain valuable insights: Get a complete overview of the challenges faced in your last production runs.

- Enhance efficiency: Save everyone’s time by enabling them to access the log file quickly and effectively.

6. Workflow

Work instructions describe how activities should be executed in a batch process like raising the temperature, mixing the ingredients, duration of the mixture, acquiring samples for testing, and much more.

The workflow module of the MES software will allow you to:

- Generate an electronic batch record.

- Collect all process parameters, including process temperature achieved and material lots recorded during process execution.

- Checks whether the operators are following the process steps.

- Prepare a workflow quickly and efficiently while defining the manufacturing process in the MES system.

- Show instructions to the operator via the screen.

- Navigate the workflow using process parameters.

- Collect lot numbers for tracing business processes.

- Execute numerous ready-made shop-floor operations to execute actions.

The benefits of the workflow module are as follows:

- Manage the process: Make sure that all business processes are correctly executed.

- Enhance effectiveness: Ensure the product release process is smoothly executed.

- Keep away from customizations: Generate complicated custom logic without customizing the codes in the MES software.

- Handle exceptions: Record and report anomalies in the process quickly and easily.

7. Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is an indicator of manufacturing performance. For example, an OEE score of 100% indicates that all manufactured goods achieve 100% of the quality requirements. Moreover, it also goes on to show that goods are produced as quickly as possible without any downtime. OEE score is calculated by multiplying three attributes, namely performance, availability, and quality.

The features of the OEE module of the MES software are mentioned below:

- Generates OEE score for all production processes within seconds.

- Enhances production capacity without installing new production lines.

- Creates benchmark plants in multi-site manufacturing groups that provide an anchor to measure the productivity and effectiveness of associated plants.

- Improves efficiency that helps bring down operational costs, such as overtime and the number of shifts & production lines.

- Displays your production team’s performance in real-time through the OEE dashboard.

Please find the benefits of the OEE module in the points mentioned below:

- Enhance your bottom line: OEE will help you make incremental gains that significantly enhance manufacturing performance in the long run.

- Anchoring: Create a benchmark to set targets for measuring production line effectiveness.

- Continual improvement: Recognize the best production runs to set better goals for the future.

- Improve visibility: OEE dashboards provide real-time visibility about the production process by generating reports.

- Enhance effectiveness: Perform accurate OEE analysis without running multiple data sets on spreadsheet software.

8. Labor tracking

Labor costs are an essential part of the overall manufacturing expenses, and therefore it’s crucial to manage them. Generally, a company decides the headcount per shift during the planning phase. But it’s challenging to track the deployment of labor per shift throughout the manufacturing facility. This is where the labor tracking module comes into play.

The features of the labor tracking module are as follows:

- Track details of people working across all the production processes.

- Record person-hours across each shift by order and line.

- Trace how many hours are spent on non-production activities like cleaning.

- Decide how much workforce do you require across each production activity.

- Collect workforce data and send it to ERP for calculating wages.

- Compare actual hours and planned hours.

The benefits of the labor tracking module of the MES software are as follows:

- Tracking: Trace which module has been assigned to each person and their progress rate.

- Cost control: Minimize labor cost by tracking labor hours per order.

- Effectiveness: Monitor reports to check where the labor costs deviate from planned costs and how much.

9. Production Counting

Counting the number of finished products during high-speed processes is challenging. As a result, companies often don’t know when to halt the production process that wastes a lot of money, workforce, and time.

The production counting module in the MES software help:

- Calculate the accurate cycle times.

- Handle the production speed appropriately.

- Generate real-time production statistics for each production process.

- Record counts in varying units of measures, such as Kg, cycles, meters, and much more from multiple machines in the process.

- Calculate efficient KPIs like Actual Cycle Time and Production Efficiency.

The benefits of the production counting module in the MES software are:

- React smarter and faster: React to factory challenges in a more agile way.

- Greater visibility: Trace order progress during the production activity.

- Continuous enhancement: Figure out actual cycle times and find production efficiency across the plant.

- Enhance effectiveness: Save the operator’s time by minimizing errors and automatically gathering data.

To learn about how Sage X3 can help improve your business, read the following solutions capability guide.

FAQs

1. What Is Manufacturing Execution System (MES) Software?

Manufacturing Execution System (MES) is a centralized production software system for managing all production-related activities, including planning and scheduling orders, calculating equipment effectiveness, tracking cycle time, labour hours and downtime.

2. What does MES do in manufacturing?

The purpose of the Manufacturing Execution System (MES) software is to make sure that all production processes are fully synchronized and executed as planned to improve production efficiency and quality control while reducing downtime.

3. How Does MES Improve Production Efficiency?

MES improves production efficiency by centralizing all production-related data and monitoring the entire production workflow. Centralized data records offer a complete view a production while allowing effortless adjustments in production parameters to quickly respond to changing market demand.

4. What Key Modules In An MES Help Manage Production Operations?

MES consists of 9 key modules that help in managing production operations. They are 1. Production Planning & Scheduling; 2. Downtime Tracking & Analysis; 3. Job & Production tracking; 4. Manufacturing Waste; 5. Line Log Book; 6. Workflow; 7. Overall Equipment Effectiveness; 8. Labour tracking; 9. Production Counting.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.