Summary: Maintaining high product quality is an essential aspect of manufacturing operations. In the information age we live in, customers take product quality seriously. If you offer sub-standard quality, then you might lose a significant proportion of your existing customer base. Low-quality goods are a major turn-off for customers, and they wouldn’t take much time to shift their loyalty towards your competitors. Moreover, people don’t hesitate to share lousy feedback and demeaning comments on social media sites and e-commerce portals. Hence, manufacturing the best quality products is necessary to build a loyal customer base that talks generously about your products.

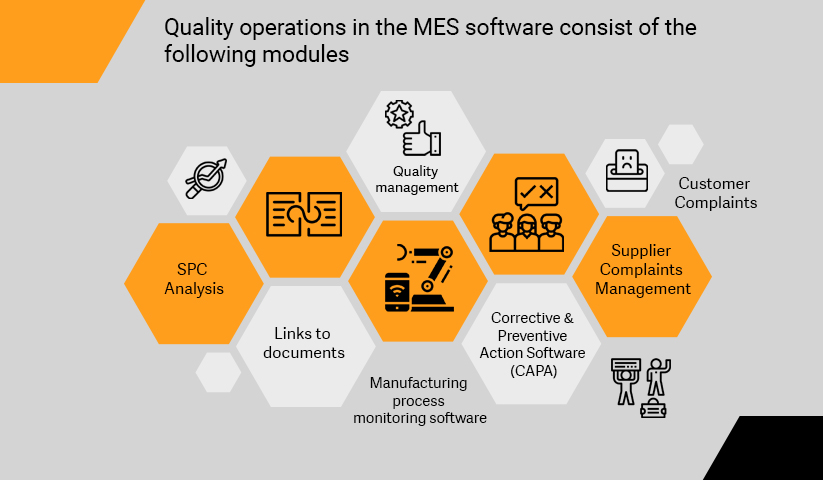

Manufacturing Execution System (MES) software is gradually becoming the focal point of manufacturing activities. It contains multiple features that take care of all the manufacturing-related activities — production, quality management, inventory, and maintenance. This article will talk about why MES software is crucial for carrying out product quality operations.

1. Quality Management

Manufacturing processes need stricter quality control to ensure the highest product quality to customers. But, on the other hand, a marginal fall in product quality can make you lose a considerable proportion of your customer base. Therefore, you need to focus on the following points:

a. How to boost product performance?

b. How to minimize the product manufacturing cost?

c. How to enhance customer experience?

d. How to ensure that the highest quality standards are met during the manufacturing process?

This module of the MES software will help you:

- Perform required quality checks across all manufacturing operations, from in-line inspections to the lab, define sample sizes, record variables, and set up attributes.

- Perform event-based checks for particular conditions, for example, out-of-spec reading.

- Describe variable specifications for single-sided tolerances.

- Records all version numbers — old and new.

- Grades attributes and variables across different levels, like minor, major, critical.

- Issues alert for issues whenever critical defects are found, or product attributes go out of control.

- The dashboard displays quality issues that allow quality analysts and inspectors to take rapid action.

The benefits of the quality management module are as follows:

- React faster and smarter: Get to know about all the issues and problems on the screen quickly. It will allow quality inspectors to identify the issues and work upon them.

- Single source of truth: All quality control plans are stored at a single location that allows relevant stakeholders to instantly access and share. You can also check whether the manufactured products are adhering to the control plan and find improvement areas.

- Increase customer confidence: Develop a relationship of trust by driving quality control plans rapidly.

- Save time: Manage exceptions quickly and get notified about various issues instantly.

- Continuous improvement: Create a database of quality data that allows quality analysts to make, measure, and sustain improvements over a long period.

>>>Also Read: Top Challenges in CRM Implementation<<<

2. Links to documents

Documents are essential for manufacturing companies as they provide crucial information related to the order, process, or work area. Moreover, they are also vital from a legal point of view.

This module of the MES software will help you:

- Eliminate paper documents from the ecosystem.

- Arrange documents based on the context, such as product specifications, Standard Operating Procedures (SOP), CAD drawings, inspection plans, and much more.

- Provide the latest version of the document, ensuring that the workforce is always working on the correct revision.

- Generate new libraries like best practice information, defect libraries.

- Supports multiple document browsers and software, namely Excel, Pdf, Word, Docs, Spreadsheets, and many more.

The benefits of the links to documents module are written below:

- Paper-free working environment: Bring down your printing and distribution costs by avoiding paper documents.

- Waste less time: Ensure that the relevant stakeholders get access to the correct document on time.

- Discard the wrong versions: Ensure that everyone is working on the latest version.

3. SPC analysis

Statistical Process Control (SPC) is a technique to track, monitor, and control manufacturing processes through statistical methods. You can check critical attributes like internal systems’ issues, analyze process behavior, and identify solutions to enhance the process.

The features of the SPC analysis module of the MES software are:

- Estimate how many non-conforming products are there in the inventory.

- Identify issues and pinpoint anomalies as and when they arise.

- Include SPC data in the conformance certificates at a quick pace.

- Minimize material costs.

- Generate capability reports instantly.

- Produce visually appealing SPC charts with multiple views.

- Perform multi-headed analysis of processes, for example, multi-channel, multi-slicing, and multi-cavity tools.

The benefits of this module are mentioned below:

- Reduce the cost of quality: The MES software will set an appropriate sample regime that will help you collect only business-critical data, thereby allowing you to use your time effectively.

- Continual improvement: Track process capability over a period, effectively tracking and sustaining progress.

- Ensure customer requirements are met: Many customers expect companies to use SPC software to understand process variation. You can also provide easily understandable reports to depict that process parameters are under control.

- Minimize scrap: The SPC module sends alert reports that allow operators to act before scrap is produced.

- Enhance quality: You can avoid waste, reduce issues, and make process adjustments by managing and reducing variation with MES software.

4. Customer complaints

Customer satisfaction is one of the most important aspects of any business. Ample researches by behavior scientists have shown that higher customer satisfaction often translates to better customer retention and more sales. Do you know that it’s five times more expensive to acquire customers than to retain the existing ones?

The features of the Customer complaints module of the MES software are explained below:

- A 360-degree customer complaint management system that collects customer issues in a single repository.

- Significantly increase the speed of sending replies to customers.

- Service executives can identify recurring problems and send timely responses to the concerned customer.

- Automatically assigns ownership to the idol service executive.

- Handles the complaint and changes its status as it moves through the process.

- Traces the age of each complaint and stores all associated email threads securely.

- Identify the primary reason for the problems and create a library of such root causes.

- Tracks and claims amount.

The benefits of this module are:

- Continual improvement: Create a single repository to record events and root causes of problems.

- Run business processes smoothly: Create system guidelines that ensure business processes are running efficiently and are getting completed within the set deadlines.

- Enhance response rate: Respond to customer complaints more effectively.

5. Corrective and Preventive Action (CAPA) Software

Companies need to ensure that the concerns raised in the manufacturing process are solved quickly and efficiently, and the highest quality standards are always maintained.

The features of the CAPA module in the MES software are as follows:

- Avoid customers receiving defective products.

- Creates a platform to capture, track, manage, and resolve concerns on the go.

- Attach various types of documents such as pictures and videos while capturing the problem.

- Assign ownership to a particular employee for handling an issue/concern.

- Record the age of every complaint and send email alerts to escalate the issue.

- Support continual improvement activities by creating a history of concerns.

- Investigate whether a preventative action was successful?

- Notify groups/individuals about a concern instantly.

- Trace the progress of each concern and the associated actions taken to mitigate it.

- Create a workflow to manage concerns and to check their status as they move through the process.

The benefits of this module are:

- React smarter and faster: Automated notifications, real-time traceability, and escalations management resolve non-conformance-related issues conveniently.

- Continual improvement: Create a repository of events and root causes that help solve issues at lightning speed.

- Respond to adverse events conveniently: MES software will allow you to execute corrective and preventative actions efficiently.

>>>Also Read: Efficient Quality Management in Sage X3<<<

6. Supplier complaints management

Find the best suppliers, vendors, and distributors by checking their performance and efficiency against set benchmarks.

The features of the supplier complaint management module are as follows:

- Critically examine the suppliers’ performance over a particular duration.

- Check the status of the supplier issues using the complaint management module.

- Attach essential documents, including delivery notes, supplier certificates, and pictures showing defects in the supplier’s materials.

- Get a 360-degree picture of each supplier’s performance over a given period.

- Record supporting data such as date of the complaint, supplier, quantity affected and received, nature of the complaint.

- Trace complaint progress and associated actions.

The benefits of this module are written below:

- Create a single source of truth for all supplier-related issues.

- Use MES data to ensure that suppliers’ materials are of top-notch quality.

- Use data to measure incremental improvements in the supplier’s performance.

- Examine each supplier’s performance by recording their history of issues in a single repository.

7. Manufacturing process monitoring

With MES software you can monitor complicated manufacturing processes involve various parameters like pressure, temperature, cooling, flow rates, moisture, speeds, and environmental factors. The manufacturing process monitoring module captures these data points and ensures that the process runs well within defined limits. It also identifies issues by examining historical data and provides insights to resolve them.

The features of the manufacturing process monitoring module of the MES software are mentioned below:

- Records and displays key parameters to operators allowing them to know that the processes are running smoothly and efficiently.

- Examining and running historical reports, thereby revealing hidden insights.

- Records and alerts operators about process parameters like temperature, time, pressure, and speed, thereby allowing them to respond to technical issues rapidly.

- Allows operators to add new parameters conveniently.

- Alerts operators if the process parameters move into the danger zone.

- Gather and examine data across hundreds of parameters.

To learn about how Sage X3 can help improve your business, read the solutions capability guide.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.