Summary: A product recall can affect a company’s business processes. The food and beverage industry faces pressure to follow the regulations imposed by food regulatory bodies to curb health risks. In the year 2021, FDA identified 414 product recalls in the food and beverage industry. Anytime this industry should be equipped with the right plan and decisions to effectively manage ahead of a product recall.

A product recall can have drastic effects on a company. It is a process of removal of a product from the market following an issue. A product is recalled instantly if it’s defective or found unsafe for the consumer to utilise the product. The faulty goods are checked later, corrected or obliterated. The company takes responsibility for withdrawing its products from the shelf by alerting the public, retailers, distributors and manufacturing partners.

For example, a few years ago, a renowned food and beverage company instantly recalled tons of noodle packets for violating the regulatory standards of FSSAI.

A company must take immediate responsibility to avoid causing severe legal, financial and safety issues. If the business takes on the challenge appropriately, it will receive praise for its practical and prompt action. However, the company should have a plan of action in case of a product recall.

Effects of a Product Recall

A product recall can put a company at risk if the right action plan is not executed. A company recalling a product will have to go through legal and financial issues, damaged reputation and sometimes the business dies. Consumers majorly face a health risk if the products are not removed. Let’s look at the effects of withdrawing a product from the market.

1. Lost Customer Loyalty

A company may lose loyal customers if they fail to own the mistake of the defective product. Taking prompt action to retrieve the products from the marketplace can set things right with the customers. Offering them compensation for the damages can change their perspective.

2. Brand Reputation

Product recalls can have a significant impact on a brand. It can diminish or end the reputation of the brand. According to a survey, 55 percent of the customers switch the brand for a similar product after a product recall. Nowadays, customers can quickly respond through social media, significantly dampening the brand’s reputation.

3. Expensive Legal actions

Companies incur heavy financial burdens during a product recall. They have to pay financial penalties to the regulatory bodies for violating the standards. Plus, they have to pay a hefty amount to the inflicted customer. Legal action costs a great deal.

4. Positive Brand Image

Your brand’s image may change the way you recall your product. It reflects the commitment you have toward customer safety and product quality. Your prompt actions and decisions impact your business in this critical time.

Reasons for a Product Recall

A product is retrieved from the market to prevent consumer health risks and to save the brand’s reputation. Let’s look at the factors resulting in a product recall.

- Poor maintenance of manufacturing facilities and equipment.

- Manufactured products not complying with the standard regulatory boards.

- Product not in compliance with the company’s regulatory standards.

- Failing to monitor the manufacturing process.

- Using low-quality raw materials.

- Issue detected on product during spot check.

- Tracking issues of the product in the supply chain.

<<<Also Read: 9 Supply Chain Tips to Effectively Manage a Product Recall>>>

Effective measures to manage a Product Recall

Before a product recall occurs, a company should be equipped with a plan to face this issue. They should possess all the requisites to tackle the problem without destroying its reputation. A well-curated game plan for product recall can enhance the communication between the company and the customer. It displays the company’s core values of commitment, honesty and responsibility. So how can you manage the product recall situation?

- Strategies to manage a product recall will differ depending on the product type. For example, a batch of noodles adulterated with some chemical will be recalled differently than microprocessors. So based on the product a company manufactures, each company should own a policy to combat a product recall.

- Do extensive academic research and develop a policy to manage a product recall.

- Maintain database of the product and customer information. Give serial numbers for all the manufactured products so it would be easy to identify them during a recall. Also, keep a record of the customer information to track them easily.

- Delays reflect a negative image of the company. Plus, it can increase the damage and penalties. Note that shareholders, regulators and customers evaluate your actions during lawsuits.

- A product recall impacts legal, financial, engineering and customer service departments. All these departments will have to coordinate and deal with the problem. Appoint a manager to integrate and perform functions without any confusion. It improves transparency which helps to solve the issue efficiently.

How Product Recall plays a vital role in the F&B Industry?

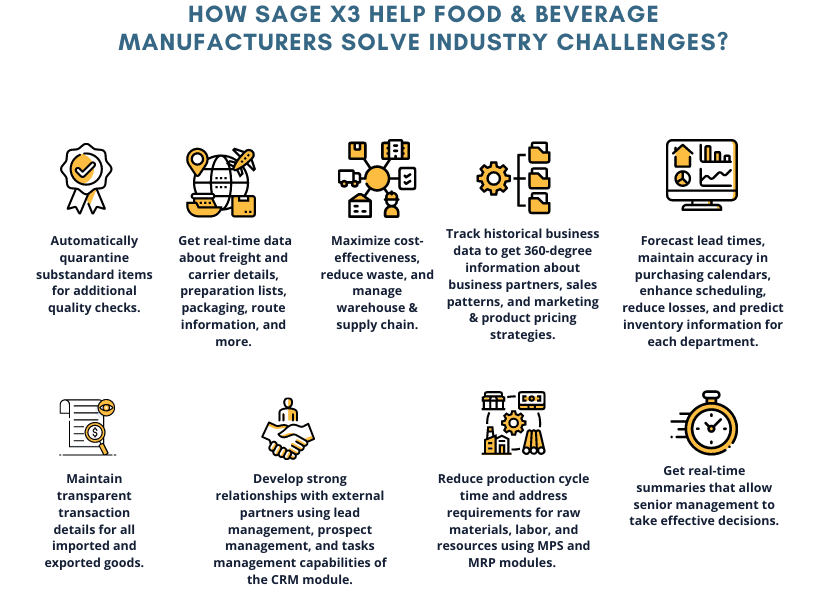

ERP Systems are widely used in companies to balance the workflow and perform day-to-day business activities efficiently. It integrates all the business operations under a single database for clarity and increased productivity. Organizations that installed fully automated ERP software have seen tremendous growth in profit margins.

ERP system plays a crucial role during a product recall. The information repositories in the ERP software give data on the defective product and the customer information. The manufacturer can track the development and retrieve all the faulty goods.

In the food and beverage manufacturing industry, hygiene is a significant criterion. The food and beverage industry is constantly under pressure to comply with the high standards of regulatory bodies. Manufacturers must adhere to all the specific regulations to prevent cross contaminations, remove allergens, and prevent accidental mixtures of toxic chemicals.

Significance of ERP software on Product Recall in the Food and Beverage Industry

ERP system is essential in the course of a product recall. The company’s timely response and cautious action may put its organization in a positive light.

- An ERP system can aid in tracing batches of defective goods immediately. Each product is registered in the ERP repository with a serial and batch number, making the traceability effortless.

- ERP system alerts the manufacturing executives to comply with the regulatory standards by sending notifications and reminders.

- As all the data is registered in an ERP system, it will be easier to identify the root cause of the defective commodities.

- Amidst a product recall, an ERP system helps in maintaining effective communication between suppliers, stakeholders and customers.

- Real-time reporting is a vital feature of ERP software systems in assisting the authorities in making quick and meaningful decisions during a product recall.

ERP solutions are robust, user-friendly software for preventing and overcoming a product recall. Its multiple features help the food and beverage industry follow all substantial safety standards to avoid mishappenings. It is an incredible system that gives accurate product information, the ingredients used, and the formula followed. All this information helps eliminate human errors and terminates misinformation. In a single database, it integrates all the functions from finance to recipe management.