What is Sugar ERP Software?

ERP for sugar is an integrated platform which automates the work in real time along different departments of sugar manufacturing business. It brings efficiency and productivity in the workflow of the organization.

Sugar ERP manages all the process right from procuring sugarcanes to making of sugar and looking after the sales & customer service.

It covers every aspect of business, like storing harvesting details, transporting details, sugar & cane billing, budgeting, cane procurement, cane pricing, cane inventory management, chemical lab reporting and equipment maintenance.

ERP for sugar industry has different modules of distribution network planning, Godown management, harvester billing & accounting, transporters billing & accounting, crop stock management system, quality management system, production analytics and reporting, Master Production Scheduling (MPS), Material Requirements Planning (MRP) etc.

Overview of Sugar Industry in India

India is one of the largest producers of sugar in the world which is the key ingredient in almost every household and also is the raw material for other businesses like food & beverage industry. Yearly around 359 LMT of sugar is produced in India.

In India sugar industry is divided into two categories i.e. organized sector and unorganized sector. Sugar factories belong to the organized sector and those who produce traditional sweeteners like Gur and Khandsari fall into unorganized sector.

Sugar Manufacturing Industry in India is important as it provides employment to around 5 lakh workers in sugar mill and livelihood to 50 million rural sugarcane farmers. Also, jobs are generated through ancillary activities like transport, trade servicing of machinery and supply of agriculture inputs.

Sugar manufacturing in India is labor-intensive, with many steps carried out manually, hence it is very much required for this industry to automate majority of the processes and meet the ever-increasing demand and supply methodology of sugar industry.

Major Processes involved in Sugar Manufacturing

Sugar ERP System is a sugar business management system which includes and manages all the process and operation of sugar manufacturing from plant harvesting to the delivery and supply chain of processed sugar which is ready for sale. Sugar manufacturing has a long process of crushing, clarification and crystallization, as defined below:

- Procurement and cleaning of sugarcanes or beets.

- Extracting juice by pressing sugarcane

- Obtaining crystals by boiling the juice.

- Spinning crystals in extractors and creating raw sugar.

- Process of filtering and washing the raw sugar and discarding the remaining elements and hue.

- Crystallizing, separating and drying of crystalized sugar.

- Packaging of the ready sugar

During the various process of manufacturing, many components and mixtures are used to extract and purify the sugar, so proper quality control measures are to be taken care of so that the final product meets industry standards.

A strong enterprise resource planning (ERP) with proper integrated cane management system will efficiently address the complex requirements in the sugar production process. Along with this an automated software will help in major activities of business process like procurement, supply chain, regulatory compliance, vendor details, production process, various reports, accounting, sales information, order tracking and customer requirements.

» Also Read:- What does Industry 4.0 Revolution mean for Indian Manufacturing Industry?

Major Challenges Faced by the Sugar Industry

Multiple challenges are faced by sugar industry for successful management of business including both internal and external challenges like dealing with farmers, local authorities, dock workers and shippers. It also deals with increasing industry challenges like changing weather, government policies, regulatory compliances, short crushing season, fluctuating production trends and high cost of production which makes the use of business management system a must.

To meet the challenges of a complicated Labor and process intensive industry such as Sugar, an ERP software is required which manages its internal and external resources optimally. Sage ERP has many industry specific modules which can be configured keeping in mind the practical challenges associated with the Sugar Industry. Some major challenges of sugar industry are discussed below:

→Machine Related Risk-

Sugar manufacturing is a heavy industry with occupational hazards and machine related risks. The timely maintenance of industrial equipment’s is a must to prevent downtimes. Also, material blockages, jams, adjustments or cleaning of systems with difficult access, can often cause work-related accidents. An ERP system with maintenance management software module can be useful to figure it out before time.

→High Production Cost-

Sugar production process poses heavy excise duty and high cost of manufacturing due to increased cost of sugarcane, inefficient technology and uneconomic process of production. Many sugar industry in India is operating at low level which finds difficult to manage the operations efficiently with the increasing costs.

→Low Yield of Sugarcane-

Although India is a large producer of sugar but the yield per hectare of sugar is very low as compared to other sugar producing countries in the world. This leads to short supply of sugarcane and low overall production, also the crushing season of sugar is short.

→Economies of Scale-

Many Indian sugar industries are small in capacity, so they lack economy of scale benefits. With the help of an ERP system companies can utilize and plan their resources up to the mark and gain efficiency.

How Sage ERP Software Can Help Sugar Industry?

Sage ERP for sugar industry helps in systematic farmer accounting, improved yields, better harvesting planning, cane cutting, significant fuel savings and reduction in casual labor. Sage Software Solutions helps the company in terms of making quick decision, optimizing inventory, bringing transparency and standardizing the process and production with 20+ years of implementation experience.

Sage provides Sage 300 and Sage X3 which are user-friendly integrated solution which cover all the process of sugar manufacturing from crop to sugar sale like financial controlling, budgeting, cane procurement, payments to growers, purchasing, cane pricing, inventory management system, fixed asset, cane management, chemical lab reporting and equipment maintenance.

It also stores details of allied industries like distillery, cogeneration, bio-products, etc. information of farmers/vendor, harvesting details, transporting details, quantity & quality of sugar and cane billing etc.

Further ERP Software can help you attain growth and increase your efficiency in following ways:

- It helps in proper and efficient management of by-products of sugar production and facilitates plant maintenance.

- Meet higher efficiency in reporting and decision making through data in graphs and chart formats.

- You can plan harvesting based on company’s cane crushing target and cane maturity detail.

Key Features of Sugar ERP Software

1. Streamline Financial Transactions

- Automate payment receivables and payables with AP Automation and AR Automation modules

- Streamline financial planning, budgeting, and analysis for greater accuracy

2. Real-time Data Insights

- Empowers you with powerful Business Intelligence Tools that provide real-time reports, charts, and dashboards for better decision-making

- Improve crop yields, better align your resources, and improve sustainability with access to the right information at the right time

3. Supply Chain Management

- Maximize asset lifespan with automation in the asset maintenance and repair using the Asset Management module

- Real-time vehicle and fuel tracking for better route planning and reducing fuel costs

4. Sales Management

- Efficiently manage your sales orders and close deals faster with an integrated Sales Management System

- Gain insight into real-time sales data and perform historical analysis for better decision-making

5. Streamlined Procurement

- Focus on strategic sourcing of raw materials such as Sugarcane & sugar beets with the Online Procurement Management System

- Efficiently collaborate with suppliers and benefit from cost-efficiency and better negotiation power

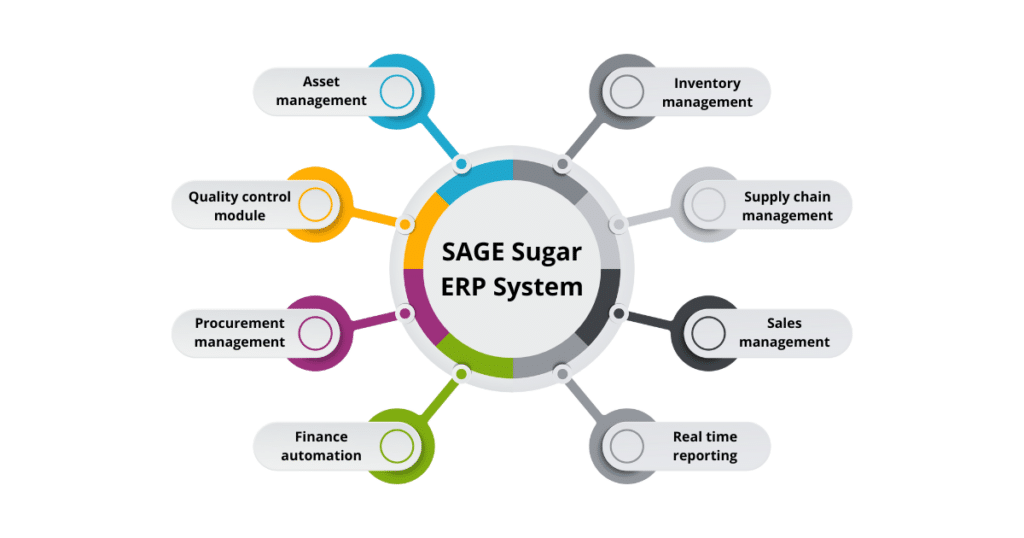

Strategic Benefits of Sugar ERP system

→Real time Reporting-

SAGE provides real time reporting for day-to-day operations like MIS reports and financial reports which are crucial for effective decision making. It also facilitates real time updates through integrated modules among different departments. You can get your real time reports as per your needs whenever required.

→Asset Management-

It’s fixed asset management software module helps in better maintenance planning of shopfloor to reduce mechanical break-down during peak crushing season and prevents downtime making work in a more organized way.

→Inventory Management-

It helps in identifying, tracking, labelling, monitoring, and controlling your business’ stock. You can keep full track of your inventory & stocks and take decisions based on it. It also provides you detail on which stock is unused and which is utilizing more.

→Integrated Modules-

Sage ERP provides integrated modules among different departments which provides transparency across working of entire organization. It leads to robust integrated data and security, further enhancing productivity.

→Quality Control-

Special module dedicated to quality control is provided to keep a keen eye on quality of goods from raw material to final finished sugar. Also, regulations and statutory compliance are taken care of.

→Supply Chain Management-

Supply chain management software monitors the entire supply chain network ensuring timely delivery of sugarcane and other raw materials. And enables real time tracking of goods.

→Procurement Management-

Sage sugar ERP helps companies automate their complete source-to-pay cycle, including purchase invoices and vendor management through automated process.

→Finance Automation-

Finance automation eliminates manual tasks, reduce human intervention and automates invoice and cash flow. Thus achieve your financial goals through financial accounting system.

→Sales Management-

Sales management system aids in managing subcontractor and contractor details and expenses. Helps meet you sales target and track sales conversions. One can also receive sales notifications.

→Fluctuating Production Trends-

Sugarcane has to compete with other food crops like cotton, oil seeds, rice, etc. Thus, it affects the supply of sugarcane to mills causing fluctuating production. Also, the introduction of other sugar substitutes in the market leads to fluctuate the trends.

Also Read:– 6 inventory management tips in the food production industry

Unleash Profitable Growth with Sage X3 Sugar ERP System

Sage X3 is a one-stop solution that helps you optimize & standardize business operations, reduce manufacturing costs, improve quality control, and meet the growing needs of your business. Streamline every aspect of your business, simplify complex business operations, and improve regulatory compliance with this highly-flexible and customizable solution tailored for your unique needs.

- Improve cost control.

- Enables Growth.

- Meet customer demand and satisfaction.

- Save time and money with automated ERP system.

- Make quicker and apt decision.

- Achieve improved production cycle.

- Gain capacity utilization

- Improved productivity

- More efficient cash collection

- Better monitoring of inventory, receivables and improved cost management due to the availability of accurate and timely on-line information

Take a step forward towards profitability. Know more about implementation of Sage Software for your sugar company. You can also write to us at sales@sagesoftware.co.in for a free consultation.