Best ERP for Food Industry in India

Optimize, grow & thrive your food business with robust Quality Control, Shelf-life, and Recipe Management features of ERP for Food Industry

F&B Industry Explained

What is ERP for Food Industry?

ERP for Food industry is a specialized software that provides industry-specific capabilities, such as formula management, shelf-life management, automated quality checks, food safety documentation, and comprehensive demand planning. It is a business-critical solution that enables the delivery of fresher & quality products to your customers, which is crucial in today’s highly competitive food industry.

ERP software automates and standardizes various aspects of your food business. It ensures consistency in the quality of your food products, while ensuring you meet a multitude of regulatory & compliance requirements. Food ERP enables decision-makers to exert greater control over their business operations, making their business highly responsive to changing market dynamics.

Decoding the Growth of India's Food Industry

India’s food manufacturing and processing industry is experiencing tremendous growth. According to a report by India Brand Equity Foundation, over the last seven years, India’s food industry grew at an Annual Average Growth Rate (AAGR) of 7.26% per annum, creating significant job opportunities and contributing to India’s economic growth. It is expected to continue growing at a CAGR of 8.8% until 2032.

The Indian Government has been actively promoting the food industry with various schemes such as Pradhan Mantri Kisan Sampada Yojana and various Production Linked Incentive (PLI) schemes. Furthermore, Indian food production & processing companies are deploying modern technological solutions such as Enterprise Resource Planning to reduce costs and minimize waste due to their game-changing benefits.

Why Your Food Industry Needs Sage ERP Software?

Sage ERP is a leader in India’s food manufacturing industry, known for fueling innovation, growth, and excellence. It empowers your business with advanced production planning & scheduling, powerful demand forecasting, predictive analytics, and financial automation. This best-in-class ERP for food industry enables decision-makers to monitor business activities, identify trends & patterns, and gain business-critical insights at their fingertips.

Here’s why leading food manufacturers across India prefer Sage X3:

- Automated alerts for food expiration, allergen tracking, and comprehensive recall management

- Gain an edge over your competitors with real-time reporting, predictive analytics, and data visualization

- Reduce online ordering complexities and provide a seamless customer experience with end-to-end e-commerce integration

- Streamline financial processes, avoid human errors, and stay compliant with regulatory requirements

- Build strategies to achieve sustainable growth in today’s increasingly complex and competitive environment

Common Challenges Faced by Food and Beverage Industry

The Food and Beverage industry faces numerous challenges that affect everything from supply chain logistics to customer satisfaction and regulatory compliance. Here are some of the key challenges:

1. Stringent Regulatory Compliance

Food safety regulations require F&B companies to adhere to strict standards concerning production, packaging, labeling, and distribution. Thankfully, the finance module in ERP helps you meet the latest financial & regulatory standards, ensure operational efficiency, and prevent non-compliance that can result in heavy fines, recalls, or even business closure.

2. Supply Chain Disruptions

Unpredictable supply chain issues, such as transportation delays, ingredient shortages, or logistical challenges, can significantly impact the availability of products. Managing a reliable supply chain that can handle fluctuations in demand and external disruptions, like pandemics or natural disasters, is an ongoing issue.

3. Fluctuating Raw Material Costs

The costs of ingredients like grains, meat, and dairy can vary widely due to factors like weather, political instability, and global demand. This volatility can impact product pricing and profitability, making it difficult to forecast costs accurately and maintain steady profit margins.

4. Waste Management and Sustainability

F&B companies produce significant waste, from raw materials to packaging. Managing waste disposal and adopting sustainable practices are not only crucial for environmental reasons but are increasingly demanded by consumers. Transitioning to eco-friendly practices can be costly and complex. Product life cycle management in ERP can do wonders in managing waste & improving environmental compliance.

5. Rising Competition and Market Saturation

The F&B market is highly competitive, with new brands and products constantly entering the market. Established brands must continually innovate to stay relevant, maintain market share, and appeal to ever-changing consumer preferences.

6. Inventory and Shelf Life Management

Managing inventory, especially for perishable goods, is challenging due to the limited shelf life of products. Ineffective inventory management can lead to increased waste, spoilage, and financial losses, emphasizing the need for accurate demand forecasting.

7. Quality Control and Consistency

Maintaining consistent quality across batches and locations is essential but can be challenging, especially in large-scale production. Inconsistencies can arise from differences in ingredient quality, processing conditions, or human error. A Total Quality Management solution should help address this issue.

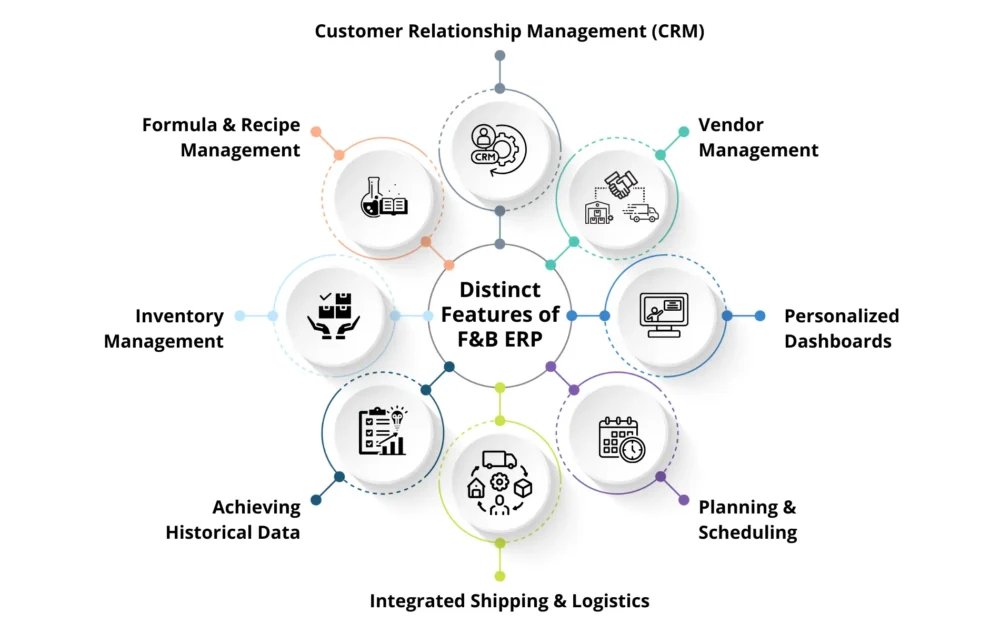

Key Features of Food ERP Software

1. Customer Relationship Management (CRM)

Sage X3 is the best ERP for food industry. It has an inbuilt Customer Relationship Management (CRM) module that serves every need of activities including lead management, prospect management, tasks management, and more.

With this ERP for food and beverage Industry, you can develop strong relationships with external partners to enhance productivity as well as responsiveness. This finally results in enhanced customer satisfaction.

2. Formula & Recipe Management

Sage X3 ERP software for food industry has brilliant features like easy operations management, product configurator, and BOM. They provide well-managed recipe and formula systems through integrated manufacturing modules.

Also, an enterprise resource planning system for food offers real-time data to customers with increased productivity and high efficiency of production activities.

ERP for food and beverage is a highly configurable system that enables tight quality controls, and consistency in the taste and quality of the food at all times.

3. Inventory Management

Sage X3 food ERP software assists in carrying out essential functionalities for inventory management. The food beverage ERP software helps with maximizing cost-effectiveness, reducing waste, efficacious warehouse management, supply chain management, and aiding businesses to gain optimum productivity. Maintaining optimum inventory levels is crucial to ensure sufficient working capital and prevent excess capital from being tied up unnecessarily. Your business can maintain a positive cash flow, and avoid stockouts & excessive stock.

4. Achieving Historical Data

Archiving and tracking historical data of the business helps attain clear and realistic information about the business partners, sales patterns, marketing strategies, and product pricing strategies.

Sage X3 software for food and beverage industry is the most comprehensive platform that offers tools that fulfill these needs appropriately.

5. Logistics Management

Sage X3 for food beverages has an excellent shipping management module. The food industry ERP software offers real-time data about freight and carrier details, preparation lists, packaging, route information, and more

With a beverage ERP, your business gains operational fluency in the cumbersome task of shipping and logistics. Not just that, ERP for food processing industry empowers businesses with automated billing & invoice generations, optimizing the physical movement of food products to save time, and money and yield higher Return on Investment (ROI).

6. Planning & Scheduling

Sage X3 ERP system offers MPS (Master Production Schedule) as well as MRP tools in order to address the requirements for labor, raw materials, and resources.

The ERP software for food distributors offers accurate results that are critical to lowering waste, reducing production time, and assisting the management in making dynamic decisions. Food manufacturing ERP provides crucial tools for determining warehouse needs, demand patterns, sales forecasting, staffing, and budgeting.

Also, forecasting offers historical data and Sage X3 assists in forecasting lead times, maintaining accuracy in purchasing calendars, enhancing scheduling, reducing losses, predicting inventory information for every department, etc.

7. Personalized Dashboards

Sage X3 food beverage ERP offers brilliant features of dashboards as well as process visuals that offer similar summaries and essential information to higher management.

The best ERP software for food manufacturing helps them make quick and effective decisions. With access to the right tools, your business gains a competitive advantage in the market.

8. Vendor Management

Vendor Management empowers your company with the ability to manage vendors, track vendor performance, and automate the Purchase Order (PO) generation. It helps you maintain good relationships with your vendors and ensure a continuous supply of raw materials for smooth production activity.

With a dedicated Vendor Management module, you will be able to get a better risk assessment of your vendors based on their previous performance and build their up-to-date risk profile. Your company will benefit from a continuous supply of high-quality goods.

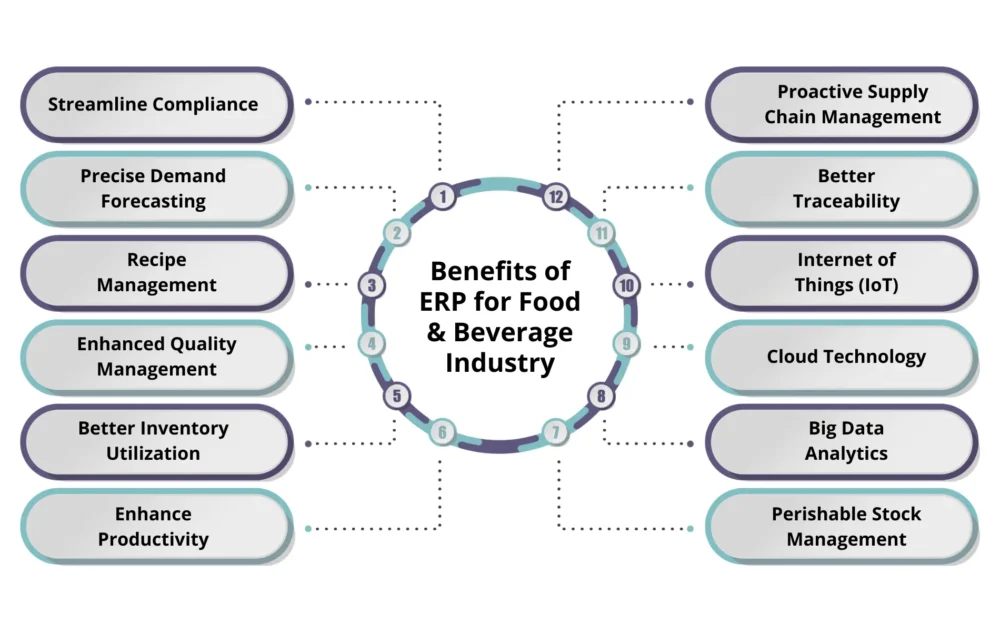

Core Benefits of ERP for Food and Beverage Industry

1. Streamline Compliance

Sage X3 enterprise resource planning is the ERP for food and beverage Industry that assists in faster compliance to help you grow your company.

The ERP food software has robust functionality that aids companies in streamlining their compliance while reducing inefficiency. It is the biggest plus point over other basic ERPs.

2. Precisely Forecast Demand

With Sage X3 ERP software, you can accurately prodigy the seasonal changes in supply and demand. This way, you can stock up as well as sell out products/services as per the needs. Sage X3, an enterprise resource planning software, offers you the ultimate intelligence in a customizable and simple interface.

3. Recipe Management

Optimize and predict varied outputs of the production job by comparing planned inputs and outputs. Use these values in the formula or recipe to start the production job through the food & beverage manufacturing ERP software.

4. Enhanced Quality Management

Food production ERP provides robust quality control mechanisms to assess the quality of your products using a plethora of information. Manage and monitor quality specifications while also testing results for raw materials, finished goods, and intermediates at different stages in the life cycle with the ERP for food and beverage Industry.

5. Better Inventory Utilization

Remove inefficiencies and manage inventory levels with incessant integration of your warehouse management. Also, reduce the inventory write-offs ( use-by-date, expiration date, etc).

6. Enhance Productivity

With Sage X3 cloud based ERP system you can compare loads on different work centers created by existing as well as proposed work orders. Also, monitor the load capacity of every work center to improve inventory levels and customer service for your business with the food processing ERP software.

7. Proactive Supply Chain Management

Sage X3 ERP software has an allergens function while allowing tracking of manufactured products. You can improve food safety along with sturdy traceability. This makes sure that you understand the ingredients’ source along with the pressures that might impact suppliers during changes in the food supply.

8. Better Traceability

There exist a number of advanced technologies that will allow your food and beverage companies to log in product and transactional information. However, the data that comes out of this information lies at the heart of traceability. Let us learn different ways to gain traceability for food beverage as a business goal.

9. Internet of Things (IoT)

With the Internet of Things, devices can get connected at any time and anywhere. Through the latest labeling technology like RFID and QR codes, accessing data becomes convenient. The data can help track the complete journey of products via the supply chain. With the ERP system, anything can be tracked and recorded right from the temperature during the transport of the products to the main resource of ingredients.

10. Cloud Technology

Today, with the advancement in technology, food and beverage companies can leverage cloud technologies. Cloud technology has varied managing aspects such as operating systems, databases, applications, and system infrastructure.

The cloud-based ERP saves a huge time and cost for your company while allowing you to focus more on crucial operations.

11. Big Data Analytics

Big data analytics helps to identify the issue in the process while stopping it from getting spread in the supply chain. In the case of potential rises, and unplanned events like contaminated products found in the supply chain, you can track and identify everything to get accurate solutions.

12. Perishable Stock Management

The inability to manage perishable food products can lead to wastage and additional production & storage costs. ERP for food industry comes to the rescue of food vendors who always struggle to keep their food fresh & eatable by providing them with superior Predictive Stock Management capabilities. They can leverage Batch Tracking, First-in-First-out (FIFO method), Last-In-First-Outand (LIFO method), and various other technologies.

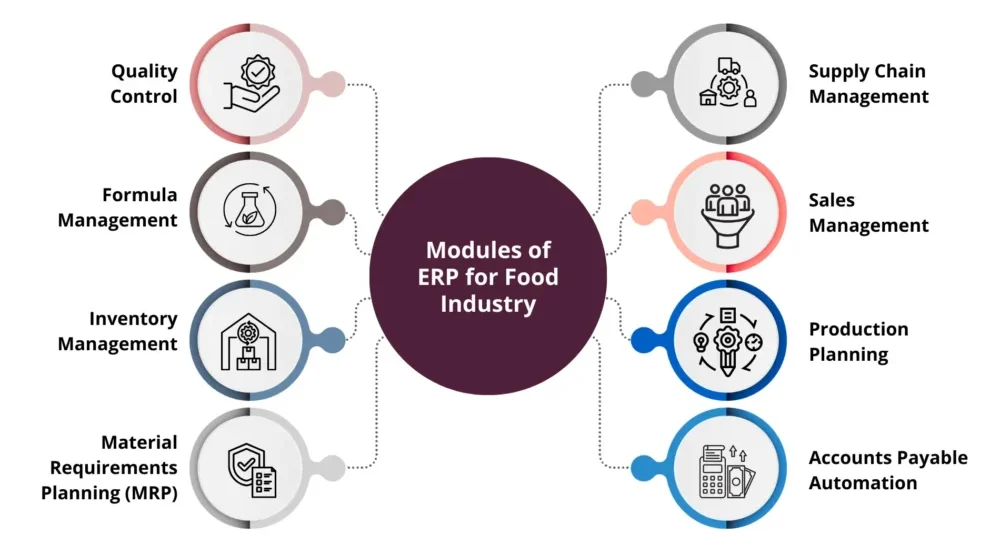

Must-have Modules of ERP for Food Industry

1. Quality Control

Food companies have to comply with various safety standards to ensure that food products are safe for human consumption. The Quality Control module provides robust quality control across different areas of the manufacturing process and generates automated alerts whenever ingredients are near their expiry dates.

2. Formula Management

In today’s era when businesses offer a diverse range of products catering to different customer segments, manually managing food formulas can be a time-consuming and complex task. ERP takes care of everything from ingredient measurement, formula sizing, and formula approval, among others.

3. Inventory Management

The Inventory Management System in ERP makes it easier to manage perishable food products with limited shelf value. It automatically checks the inventory threshold, and ensures you never run out of stock. Eventually, it helps you save inventory storage costs, and gain agility in the business operations.

4. Material Requirements Planning (MRP)

The Material Requirements Planning (MRP) module plays an important role in ensuring continuity in production operations, prioritizing & scheduling production processes, optimizing production resources, and ensuring timely delivery to the customers.

5. Supply Chain Management

In today’s era, when businesses have to adhere to strong regulatory standards, Supply Chain Management in ERP plays an important role. It provides end-to-end traceability into the production process right from the procurement of raw materials to their delivery to the final consumer. Higher transparency in the movement of goods also aids product recall operations.

6. Sales Management

The Sales Management System in your ERP provides your organization with complete control over the sales operations from maintaining extensive records of sales operations, and generating invoices & quotes, to tracking leads.

7. Production Planning

ERP equips your company with powerful production planning & scheduling features that result in continuous production activity, reduced downtimes, and improve your ability to meet market expectations.

8. Accounts Payable Automation

As your business grows in size, you will need a flexible AP Automation system that will automate invoice routing, data extracting, and data validating. Automating accounts payable will allow you to benefit from better fraud protection, collaborate with global teams, and make timely payments to your suppliers.

Who Benefits Most from Food ERP Software?

Different business segments within the food industry benefit from the Food ERP 2.0. Here are the examples:

1. Food Manufacturers and Processors

The food and beverage ERP solutions allow dairy processors, bakery product manufacturers, and meat processors to manage their day-to-day activities, track raw materials, optimize production schedules, and ensure adherence to quality standards.

2. Food Distributors and Wholesalers

Wholesale distributors of fruits, vegetables, seafood, and packaged goods use ERP for food industry to manage orders efficiently, integrate with multiple distribution channels, and track inventory.

3. Restaurants and Food Service Chains

Fast-food chains, fine dining restaurants, and catering services use the food ERP system to track costs, manage procurement, forecast demand for their products, and maintain consistency in the quality.

4. Packaged Food and Beverage Producers

Manufacturers of snacks, frozen foods, bottled beverages, ready-to-eat meals, and canned goods use the food ERP system to track production batches, manage food expiration, and streamline distribution.

5. Organic and Specialty Food Producers

Organic food producers, health-focused snack companies, and artisanal food brands use food and beverage ERP solutions for comprehensive ingredient tracking, quality parameter monitoring, and meeting customers’ high expectations.

6. Exporters of Food Products

Leading exporters of spices, tea, coffee, grains, and processed foods use food and beverage ERP software to improve traceability, comply with global food safety & security standards, handle currency variations, and reduce business complexities.

7. Frozen and Perishable Goods Suppliers

Food and beverage ERP systems are increasingly used by suppliers of frozen vegetables, dairy products, seafood, and poultry to manage temperature-controlled storage, fast logistics, and inventory rotation. They aim to reduce spoilage & wastage.

8. Nutritional Supplement Producers

Producers of protein powders, vitamins, and health supplements use a food and beverage ERP software for formulation management, batch tracking, quality testing, and regulatory compliance.

9. Agri-food Companies

Producers and suppliers of grains, spices, oils, and farm-fresh produce use an ERP for comprehensive demand planning, quality assurance, and streamlining their distribution networks.

10. E-commerce Food Retailers

Online grocery stores and direct-to-consumer snack brands use an ERP for smooth order fulfilment, automated inventory replenishment, and providing a seamless experience to customers.

Your Regular Food ERP vs Sage Food ERP 2.0

Here’s what you gain by migrating from your ordinary Food ERP software to Sage Food ERP 2.0:

| Feature | Regular Food ERP | Sage Food ERP 2.0 |

|---|---|---|

| Implementation | Primarily, On-premise | Cloud-first solution |

| Third-party Integration | Limited integration | Supports deep integration with your existing legacy tools, e-commerce platforms, and more. |

| Costs | Higher upfront costs (license fees & hardware upgradation) | SaaS pricing model (Saves high upfront license & upgradation costs) |

| User Experience | Complex (Requires longer training & focus) | Smart, easy & intuitive |

| Business Intelligence | Descriptive | Predictive |

| Traceability | Bi-directional Lot Traceability | Hyper-traceability |

| Data Flow | Syncing of data across different departments occurs in batches at the end of the day, leading to potential delays | Real-time data syncing ensures access to the up-to-the-minute & most accurate information |

Explore more about Food & Beverage Industry

Top Industries Leveraging ERP Software

Food & Beverage

Alcohol

Pharmaceuticals

Advertising

IT Services

Furniture

Manufacturing

Auto Ancillary

Pharma Trading

Packaging

Medical Device

Chemical

Plastic

Brewery

Logistics

Automotive

Food & Beverage Industry FAQs

What is the ERP system in the food industry?

ERP for food industry is a single integrated solution that allows food manufacturers to manage various aspects of their business, such as food formulas, quality checks, expiration alerts, and food safety & compliance.

What is ERP in the beverage industry?

ERP for beverage industry is tailor-made software that provides end-to-end control over your business operations to capture endless opportunities, support faster decision-making, and achieve rapid business growth.

Why is Sage X3 preferred in the F&B industry?

Sage X3 is the most commonly preferred tool in the F&B industry. It is a strategic solution that transforms your traditional business processes so that you can reduce costs, deliver food faster, and improve customer relations. It provides a comprehensive set of features to gain lot & serial traceability, manage product recalls efficiently, minimize food wastage, and prevent supply chain issues.

How to choose the right Food ERP?

Here are some tips and tricks to choose the right ERP for food and beverage Industry:

- Robust formula/ recipe management functionality

- End-to-end compliance management and nutritional labeling

- Batch tracking capability for streamlined production activity

- Complete control over production, distribution, and sales operations

- Integrated cost tracking functionality for better cost control

How Does Sage X3 Transform the Functioning of Food Companies?

Sage X3 is a next-gen food ERP 2.0 that addresses unique challenges faced by the food industry. From tackling food wastage, managing organizational resources, and ensuring quality checks at every level, to financial automation, it is a complete solution to transform your traditional food manufacturing processes.

What are the core features of ERP Software for food and beverage industry?

Here are the core features of the best ERP Software for food and beverage industry:

- Recipe & formula management

- Bi-directional tracking and Lot traceability

- Regulatory compliance and nutritional labelling

- Integrated quality control

- Material Requirements Planning (MRP)

- Master production planning and scheduling

What are the Examples of Food ERP Software ?

Here are the examples of the most popular food ERP software:

- Sage X3: Stay ahead of your competitors with better control over operations, industry-tailored features, quality assurance, intelligent demand planning, and extensive customization.

- BatchMaster: Offers integrated tools for recipe management, nutritional labelling, and bi-directional traceability

- Plex ERP: Manage complex food production processes, improve supply chain, and overwrite disconnected systems.

- Infor ERP: Better manage food safety, manage product recalls, and get cloud integration.

- Microsoft Dynamics 365: Automate core business processes, and ensure quality, consistency & strict adherence to FDA, HACCP, and FSMA standards.

What are the best practices for the Successful Implementation of Food ERP Software?

Here are some best practices to get the best out of your food ERP software and maximize your ROI:

- Coordinate with different teams and assign roles & responsibility

- Develop an implementation roadmap and allocate sufficient budget

- Get access to a range of features by choosing the best ERP software in India

- Don’t go live without thorough planning and testing

- Customize the food ERP software for your unique business requirements

- Collect employee feedback regularly to ensure reliable performance & effcieincy

- Evaluate your performance with the Key Performance Indicators (KPIs)

How does Food ERP improve food traceability & compliance?

Food ERP offers superior batch tracking capabilities, end-to-end documentation, and automated compliance to ensure full regulatory adherence and minimize potential fines & penalties. It helps your business adhere to all the food quality & safety standards with automated quality checks and backward & forward tracing of your produce.