Summary: Inventory management techniques is one of the most important factors of supply chain management. It is the process of tracking stock standards as well as movements of goods. In this post we will have a glance at the most trending inventory management techniques that SMEs must follow to grow their business.

What is inventory management?

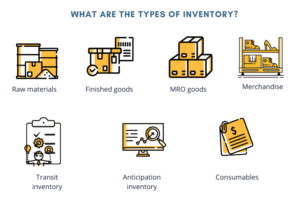

Inventory management is tracking your products and ordering them before they get stock out. It also includes accounting for the products available in a warehouse and raw materials needed to keep the business running. But, inventory management is a pivotal platform that is more than just accounting and revolves around predicting the business conditions to ensure the proper availability of products, supplies, and raw materials. Efficient inventory management techniques can help organizations save time and money while maximizing sales ratios.

So, let us learn some unique inventory management techniques that SMEs must follow to grow their business.

Choose your inventory method wisely

Efficient inventory management techniques varies with the business you own. Suppose you own a food business, then perishable products would be involved in selling the inventory on the FIFO basis (First in, First out) method. It clearly shows that the old products will be depleted first. Today, organizations have been deploying the FIFO strategy extensively since it helps gain a better impact on the bottom line.

<<Also Read: 10 Inventory Management Trends to Watch for in 2023>>

Precise forecast demand

One of inventory management techniques is accurate forecasting. Usually, inventory executives depend totally on the data to track utilization, including records of past sales, seasonality, market trends, and top-notch technologies like the predictive analysis. These elements make data-informed and quick decisions. Moreover, to get precise forecasts, inventory executives should also consider some additional factors such as economic health, weather, demand shifts, and much more. Accurate forecast demand help increases sales opportunities to a great extent.

Track stock standards

Tracking specific items already used in product development or representing goods to customers for sales helps executives maintain order processes accurately. It is one of inventory management tactics. However, a well-established document and continuous inventory cycle counting help reduce errors that might impact the overall availability and product access. Also, you need to create automatic reminders in your inventory management software so that inventory executives would get alerts when a few items are stocked out. Not least, tracking stock levels helps manage product demand.

In order to track stock standards, SMEs can also leverage ABC analysis which helps optimize inventory turnover rate while lowering the obsolete inventory to a greater extent.

Audit stock needs regularly

The inventory management of SMEs should be precise enough. To ensure enhanced accuracy, you should always get the right software and the appropriate policies and practices. Experts have been suggesting that the more you match your requirements and the management software, the better your inventory management techniques will be.

However, the inventory standards should always be affected by different factors, from the shortage of stocks to their unsafety. Consistent auditing of stocks helps find many data entry issues and other inventory problems. The best-in-class inventory management techniques can always pave the path to tremendous success in business.

Also Read: What is ABC Analysis in Inventory Management System?

Get focused on quality control

Unlike other management processes, inventory management also needs a higher focus on quality control, which is undoubtedly critical. This is why companies should be highly focused on deploying quality inspections during the product lifecycle. It helps minimize waste while meeting business standards. Accurate documentation, invoice matching, precise ordering, and implementation of quality control in every facet of inventory have the utmost importance. Also, it is essential that every executive understands the process well and makes it in the place.

Maintaining and creating a work culture that would focus solely on improving quality at every step of the inventory process is quintessential. To bring standard quality control policies across all levels of the company culture, SMEs should get reviews from their employees regarding the quality control check process.

Then, once a primary line for the overall survey is placed, you can set goals for improvement through customer feedback, other inventory returns, and more factors. To get better results SMEs should look into individual sectors and your company’s criteria and share their achievements so far received.

Drop-ship

With constant drop shipping, suppliers should ship products directly from their warehouses to the customers. It eliminates the need to place the product on hand and might attract concerned inventory costs. Despite manipulating every element of the product lifecycle, the most critical factor for SMEs would be the sales and marketing of products. Once you cut down the warehousing and fulfilment expense, your profit would come from the difference between marketing costs and selling/ wholesale price. However, it is equally important to build a healthy bond with a drop-ship partner that guarantees product quality and appropriate inventory management software.

Drop-shipping offers a number of inventory benefits including low business cost, low inventory cost, selling products with less risk, and more. For better results, SMEs can also deploy economic order quantity model which helps companies focus more on analyzing how much inventory needs to be ordered and when. The economic order quantity EOQ model helps managers to reorder inventory when it reaches its minimum level.

<<Also Read: The Impact of Poor Inventory Management in Discrete Manufacturing>>

Establish a POS

It is one of the brilliant inventory management techniques SMEs should leverage. POS helps SMEs track stock as well as inventory in sharp real-time. Whenever items are being sold, the software should update inventory levels and the cost of goods. POS technology is usually made at the point of sale and is used mainly in the manufacturing process to keep a precise track of raw materials and supplies.

SMEs should have a fully integrated POS software with their inventory software to get accessible ongoing and ongoing inventory. With this high-tech solution, you can easily eradicate errors from the data entry and generate highly responsive reporting capacities. For instance, you can also create dashboards with crucial data.

Get barcode system

Barcode means some alphanumeric characters and some black bars. Here, every data is firmly embedded which makes quick, easy, and more accurate inventory management. In warehouses, the barcode helps identify data about the details, location, color, or size. Also, they offer more visibility to the products and help you utilize inventory even more efficiently.

The barcode system stands among the most trending inventory management techniques that also help quick inventory count and fulfill all orders fastest. In the case of retail businesses, the barcode can easily specify product names and costs. Now, turning to the life of the barcodes, they can easily live with the lifecycle of products right from the manufacturing to their service.

Fetch inventory precisely

Some best inventory management techniques of inventory also include fetching inventory precisely. Once the merchandise is received, it must be compared and reviewed, keeping in mind the purchase order, which will ensure accuracy. However, it is essential to check that you have received the perfect item in the required quantities.

It is essential to get an accurate inventory count while receiving inventory. Also, team members should be well-trained and understand every step. SMEs advised that they should be accurate on outsets since the inventory management process would begin on a solid platform.

Keep stockroom organized

Managing the stockroom is one of the best inventory management techniques since it has a specific impact on SMEs’ efficiency of supply chain management. It would be a complete waste of time if you failed to find the appropriate inventory. Besides storing, receiving, and accessing inventory, the supply chain management should also consider rest inventory management challenges like customized services for fragile or perishable product stock.

Remember that the warehouse storage area is essential for efficient inventory. If SMEs can manage warehouse space well, they can store extra inventory while taking total warehouse leverage. This all results in controlling the expense of the business and shooting sales.

Invest in an effective inventory management software

Today, many SMEs have been using inventory management software to optimize and manage supply chains efficiently. Inventory management software aids small businesses to make they have enough of the inventory available at accurate locations while ensuring that other manufacturing activities are carried out well. It is the best inventory management technique.

After investing in software, SMEs can easily manage limited resources while ensuring greater accuracy in supply chain decisions. It is one of the dynamic inventory management techniques.

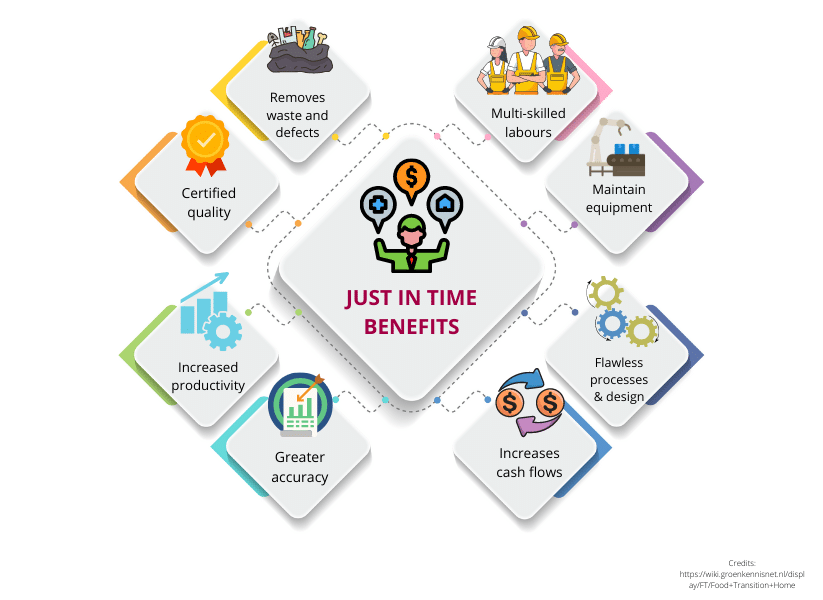

Just-in-time shipping

It is one of the efficient inventory management techniques that keep effectiveness at the topmost priority. Here, a delivery vehicle might unload items directly at the facility and ship sales to the customers at the right time. It will help eradicate the need to get new things in the storage space while making the whole inventory management process improved. If you are considering a ”Just in time” inventory shipping pattern then you can reply on cross-docking since here every item goes out for shipping once you have it in your storage.

Standardize inventory processes

The advanced technology can make inventory management processes more effective by offering data to make purchases, manufacture, and make informed sales decisions. Once you formalize and standardize the processes, it can lower human errors, and your processes will work much faster than ever before. Standardizing the inventory processes stands among the best inventory management processes in the industry.

Check low-turn stock

Checking low turn stock aids inventory managers with raw material orders during the supply chain process. The process is carried out by adjusting production results and matching products that may have no demand in the coming time. Suppose your inventory management system rectifies a languishing product on the shelf, indicating that its market has declined. It also suggests that additional efforts may need to improve its awareness. You may run promotions or shift the stock to another location where it may get sold at a better price.

<< Also Read: What is Inventory Management System >>

Utilize purchase orders

Usually, organizations make use of purchase orders to track placed orders and vendors and suppliers. Purchase orders are nothing but documents with details of the purchase, such as its quantity and price. This inventory management technique is essential to implement for SMEs to keep track of purchased stocks along with the amount of stock levels.

Make data-driven decisions

One of the best advantages of a robust inventory system is the real-time data which helps you make data-driven decisions. The inventory management software must provide every minute information on supply products and levels, stock cost products, and maximum time to restock particular items. With the help of precise data, SMEs can also predict future sales based on past purchase histories and track vendor performance. Data-driven decisions stand for the art of inventory management with critical data factors to help minimize expenses and increase business revenue.

Down the line

SMEs can save time and money with the best inventory techniques. An inventory management software can help automate the process, which reduces costs while tracking outgoing/ incoming goods. It provides real-time information required to purchase and product development decisions. So, to elevate business SMEs must implement inventory as mentioned above management strategies and experience flawless business operations.

STAY UPDATED

Subscribe To Our Newsletter

At Sage Software Solutions (P) Ltd., we are home to world-class ERP software and CRM software that will solidify your business tech support fundamentals and enable you to build a customer-centric organization. You can also write to us at sales@sagesoftware.co.in.

Disclaimer: All the information, views, and opinions expressed in this blog are those of the authors and their respective web sources and in no way reflect the principles, views, or objectives of Sage Software Solutions (P) Ltd.