ERP for Chemical Industry in India

Gain real-time bi-directional traceability, batch tracking, quality & compliance management, and information reporting at various levels with ERP for chemical industry

What is ERP for Chemical Industry?

Chemical ERP (Enterprise Resource Planning) software is an all-encompassing platform that reduces complexity in different chemical manufacturing operations such as formula management, regulatory compliance, vendor collaboration, production planning, and batch processing. It provides flexibility, customizability and a user-friendly interface to transform the traditional business processes, and adapt to the new reality.

Sage X3 is a ready-fit solution that equips modern-day chemical businesses with the cutting-edge technology & end-to-end visibility required to grow and excel in today’s highly competitive & complex business landscape. It is a multi-functional ERP Software that comes with powerful formula management tools, business intelligence tools, real-time inventory & warehouse management, compliance capability, and integrated project management functionality, among others.

Overview of India's Chemical Industry

According to a report by the International Trade Administration Department of the Government of the USA, the Indian chemical manufacturing industry is the sixth largest in the world. As of 2024, it was valued at $220 billion and is expected to reach $300 billion by 2026.

The growth in the Indian chemical industry is attributed to various factors such as the steady increase in India’s disposable income, increased focus on exports to Asian & Southeast Asian nations, and numerous Production-linked Incentives (PLIs) released by the government.

Why Your Chemical Business Needs Sage ERP Software?

Gain access to real-time strategic insights and cutting-edge technology to reshape the very fabric of your enterprise. Leverage the transformative power of business-critical modules in Sage X3 and data analytics to build superior data-driven strategies, mitigate potential risks, and propel your business towards unprecedented success.

⇒ Here’s why leading chemical companies across India choose Sage X3:

- Efficient and transparent procurement of raw materials

- Reduce operational bottlenecks and delays with a smooth order-to-cash cycle

- Complete batch tracking and improved traceability with the Batch Inventory Management System

- Improve cross-departmental collaboration with single-step data transfer

- Optimize plant efficiency and ensure continuity in the plant operations

- Measure operational performance at every level with real-time KPI metrics

What are the Major Challenges faced by the Chemical Industry?

Raw Materials

Easy access to the raw materials is quite hard since they are not available at an instant. Secondly, the costs of materials are very high in India as compared to that of the Middle East/ South Asian countries. This might occur due to the lack of skilled laborers or differences in manufacturing wages.

Poor Infrastructure

Limited or restricted access to depots, ports, poor infrastructure facilities and worst pipeline connectivity are prime issues for domestic chemical manufacturers. These issues prove to be huge obstacles in the flawless delivery of raw materials.

Also, the power supply is another major challenge that counts in the poor infrastructure. Due to a shortage of capital, small/medium-sized chemical plants cannot afford captive power plants.

Import Related Concerns

Today, chemicals are being imported from low-cost manufacturing hubs. After entering into the world trade organization, India has been facing a major reduction in importing tariffs on varied products.

To meet the growing demands of chemicals throughout the country, the government has banned tariffs which will ultimately increase the competition rate.

Issues Connected with Human Resources

The industry faces a huge shortage of skilled laborers that apparently affects the productivity of the business. However, the company has to undergo compromised product quality, reduced productivity, limited growth, and more.

Hence, companies require skilled laborers to enhance the productivity of the chemical manufacturing business which can only be achieved by having a better human resources department in the plant.

Low Working Capacities

Owing to the oversupplies of materials, the cost of petrochemicals has gone too down globally. Hence, the domestic business owners have been underutilizing their plants which is affecting the growth of the sector.

Top Features of ERP for Chemical Manufacturing

With the ascending challenges in the sector and growing demands, the only option we have is to convert these challenges into opportunities and see optimum outputs in the chemical business. These challenges can be solved by implementing the Sage Software’s business management software.

It requires a significant span of time for a company in performing research and development formulation. Through the ERP for chemical manufacturing our business can store all the relevant activities that are performed in your laboratory.

These activities might include various formulations as well as different restrictions of chemical which is intern produced.It is one of the best solutions that can also offer you the most expected cost of your recently built formulation which will be indeed based on the present cost of raw materials.You can track all new formulas as well as the manufacturing process of chemicals. Generate reports with the latest technology.

Today’s competitive world needs innovative ERP for chemical process manufacturing Industries through which they can manage all the samples and can provide regular quotations that will be based on the respective samples.

However, these samples are completely based on the fluctuations designed specifically for the raw material off the market.

With the help of ERP Implementation for chemical industry, we can generate databases of different samples and send them to the client along with the courier details.

ERP for the chemical industry integrates all business activities into a unified platform. Its record-keeping procedures bring end-to-end traceability into the system. Your business gains from increased visibility into all of its operations, and it can effectively face real-world challenges that are unique to your industry.

ERP for chemical manufacturing reduces complexities in the business operations. It streamlines everyday business operations such as generating a Bill of Materials (BOM), performing Quality Assurance (QA), and procurement of raw materials. Gain a 360-degree overview of your business operations through various charts, reports, and customized dashboards for better & informed decision-making.

The software involves various modules of supply chain execution and planning. The features look after the concerns of chemical manufacturing processes like steep transportation, inventory costs, rising costs, increased waste, and more.

The feature also helps companies to enhance cycle time with the supply chain visibility while also delivering a quick order-to-cash cycle with more accurate planning. It lets you check the total view of purchases, and check vendor performance. The supply chain feature also obtains a clear view of all evaluations, and purchases while also managing strategic reduces

Sage X3 software enables agility and helps detect the source of the problem in the case of a product recall. The software helps keep an up-to-date record of every piece of information from the operating processes. This helps chemical manufacturers stay updated with the information and aids to prepare for any major product recalls.

Moreover, the recall management feature helps chemical companies manage product sustainability, recalls, expiry management, labelling, and more critical issues for the manufacturing business.

Sage X3 Transforming Businesses Globally!

Effortlessly Streamline Processes And Achieve Unparalleled Business Growth

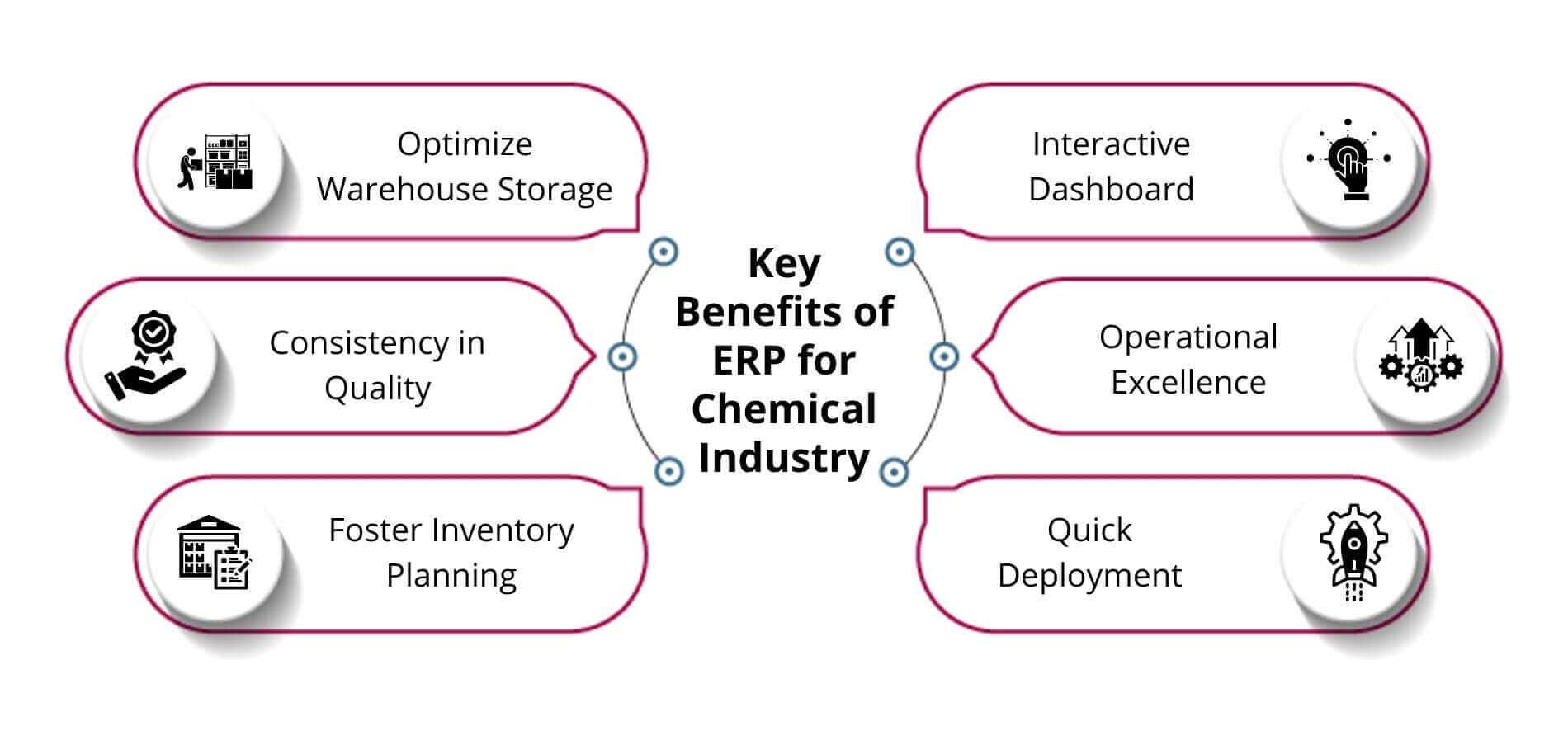

Key Benefits of ERP for Chemical Industry

An ERP provides better control over the company’s operations and empowers it with quality control, innovation, supply chain resiliency, and various other ways. Let’s deep dive into the benefits of ERP:

1. Optimize Warehouse Storage

In today’s times, warehouse costs are ever-increasing due to supply chain modernization and e-commerce booms. As the warehouse costs directly affect the company’s profitability, businesses need to proactively confront this challenge.

Bring efficiency into your warehouse operations, and transform manual workflow with automation. Make the best of modern technology and innovation to save warehouse storage, adopt best warehousing practices, fix mismanagement, and reduce costs.

2. Consistency in Quality

In today’s highly-competitive business landscape, businesses have to consistently focus on quality to meet stringent regulatory requirements, and heightened customer expectations.

Adopt the best quality control practices, and maintain consistency in the quality across the production-line. Automate quality inspections, and generation of non-conformance reports, to comply with the best industry standards.

3. Foster Inventory Planning

With ERP, you don’t need to purchase a third-party tool to plan and manage your inventory. It automates everything from order quantity calculations, stock replenishments, and real-time stock notifications to inventory reporting.

With the help of this Sage 300 ERP for chemical industry, you can choose the right inventory depending on certifications, expiry dates, as well as status while making manufacturing and distribution simpler. With a robust Inventory Management System, you can easily optimize the inventory levels with procurement and automated planning schedules for better supply chain management.

4. Interactive Dashboard

Much like how Pharma ERP Software streamlines pharmaceutical operations, the ERP for chemical manufacturing optimizes the core chemical manufacturing, distribution, human resource, and other activities.

ERP Chemical Software offers a single intuitive platform or dashboard with which you get to extract, view and assess crucial business data with a few clicks, thus offering you improved business insights. Also, you can browse through critical customer data, suppliers/vendor records and all other vital data from a unified and easy-to-use dashboard with Sage X3.

5. Operational Excellence

For a business in the chemical industry, keeping control over costs whilst meeting production needs is the key to operational excellence and Sage X3 ERP software for chemical industry helps you achieve that in a streamlined and efficient way. Operational efficiency is of utmost importance when it comes to addressing all aspects of a business to help curb costs, improve relationships with customers, etc.

Also, optimizing various operations across your entire organisation is extremely easy with Sage X3 ERP, as it offers a unified and single platform bridging together all your critical operations. Being affordable and budget-friendly, Sage X3 ERP for chemical industry is perfect for small and mid-sized businesses operating in this sector.

6. Quick Deployment

Designed to suit the specific requisites of the chemical industry, the implementation is hassle-free and quick irrespective of the size of the business. Further, all the modules of Sage X3 for chemical industry are finely integrated to allow a seamless flow of data and streamline manufacturing, production and shipping processes.

It ensures full compliance with statutory and regulatory requirements. What’s more, it also addresses excise and outsourcing processes in a seamless manner.

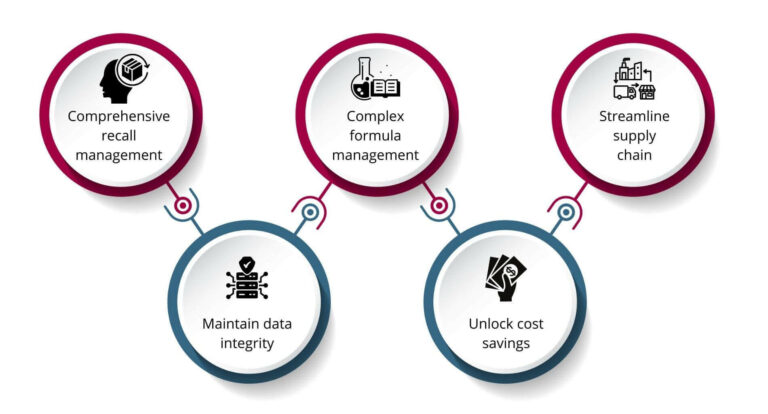

How Does an ERP for Chemical Manufacturing Work?

Curious how would an ERP deliver transformative changes and unlock future growth opportunities? Here’s how it works:

1. Maintain Data Integrity

Businesses often suffer from data silos, data quality, reliability & integrity issues. The data is often scattered across different spreadsheets, or it is incomplete or unstructured. Locate your data easily, restructure it in an orderly manner, and gain a competitive edge through ERP’s powerful data consolidation capabilities.

2. Comprehensive Recall Management

ERP supports comprehensive recall management in the event of a threat to public health or violation of the country’s laws. Maintain end-to-end traceability throughout the chemical manufacturing process, perform batch tracking and timely quality audits to protect public health and your brand’s reputation.

3. Complex Formula Management

Redefine your chemical manufacturing process, gain efficiency in your operations, and make rapid transformative changes with access to exceptional tools and strong formula management features.

4. Unlock Cost Savings

Many people perceive ERP as an expensive investment due to higher ERP cost. However, it offers substantial cost-saving benefits and increased profit opportunities in the long term. By streamlining business processes, eliminating operational inefficiencies, minimizing data redundancy, and enabling faster collections of payments, you will benefit from better financial stability in the long run.

5. Streamline Supply Chain

Increase the efficiency of your logistical and transportation operations, and make significant savings on the transportation of goods. Build contingency plans, and gain end-to-end visibility into the movement of goods as they move throughout the supply chain operations.

Unleash Efficiency & Maximize Productivity with Sage X3

Sage X3 is the central hub for managing every aspect of your chemical manufacturing business. Plan and schedule your production runs, track supplier performance, automate management of complex chemical formulas, and manage quality control data at your fingertips with this highly customizable and scalable solution.

Here’s what our industry-first Chemical ERP offers:

- Get bi-directional material traceability

- Comprehensive quality and compliance management

- Track market prices and plan your budgets more efficiently

- End-to-end compliance with industry standards

- Inventory planning, expiration date tracking, and equipment management

Explore more about Chemical Industry

Chemical Industry FAQs

What is ERP in Chemical Industry?

ERP in Chemical Industry is a sophisticated Business Management Software that streamlines the core processes of a chemical manufacturing company from procurement, manufacturing, sales, supply chain, and human resources to financial management. Moreover, it seamlessly integrates with your legacy tools for real-time data exchange.

What are the Benefits of Chemical ERP Software?

Chemical ERP Software is an all-encompassing solution that simplifies various aspects of the chemical businesses from production, formula management, and sales to financial operations. It keeps detailed audit records and compliance documentation to ensure end-to-end regulatory compliance and minimizing the risk of penalties. It enables chemical businesses to get in-depth control over their inventory, manage equipment repair & maintenance, and enhance responsiveness to changing market dynamics.

Which Software is Used in the Chemical Industry?

Sage X3 is the widely used software in the chemical industry in India and across the globe. It is a one-stop solution for all your business needs to bring efficiency to your business operations, track costs, manage resources efficiently, and ensure the availability of materials at the right time and the right location.

What does ERP stand for in chemical industry?

ERP in the chemical industry stands for Enterprise Resource Planning. It is a single platform that allows chemical manufacturers to gain visibility across their resources, adapt to new market changes, bring swiftness in the movement of inventory, and foster smooth collaboration across different departments.

What is the Role of AI in Chemical Process Designing?

Artificial Intelligence (AI) allows chemical manufacturing companies to analyze large datasets, perform batch analysis, find new trends & patterns through predictive analysis, reduce waste, and improve productivity. AI’s ability to integrate with IoT sensors reduces unexpected machine failures and prevents mishaps.

Schedule Product Tour

"*" indicates required fields