What is Maintenance, Repair and Overhaul (MRO)?

Manage high-value physical assets, enhance their efficiency & longevity, and prevent critical machine breakdown with regular Maintenance, Repair, and Overhaul.

Manage high-value physical assets, enhance their efficiency & longevity, and prevent critical machine breakdown with regular Maintenance, Repair, and Overhaul.

Maintenance Repair and Overhaul (MRO) encompasses various activities that plan, execute, and document organizational assets, machinery, and equipment to improve machine lifespan, and performance, and reduce defects, downtimes & business disruptions.

The MRO is a type of preventive machine maintenance intended to achieve long-term organizational goals and objectives. With an effective MR&O strategy, businesses can ensure that assets are running at their peaks and contributing to the growth of the organization. MR&O includes:

Maintenance: This includes all preventive activities intended to minimize machine downtimes and disruptions, and their potential impact on the regular business activities. These activities are usually carried out when the machinery is in a healthy state.

Repair: This includes all reactive activities intended to repair problems with the machinery after they are discovered. These activities aim to un-done existing damage or performance issues with the machinery.

Overhaul: The overhaul concept includes all those activities in the repair. Moreover, it involves other additional sets of activities such as machine disassembling, cleaning, and restoring the machine’s health, and performance.

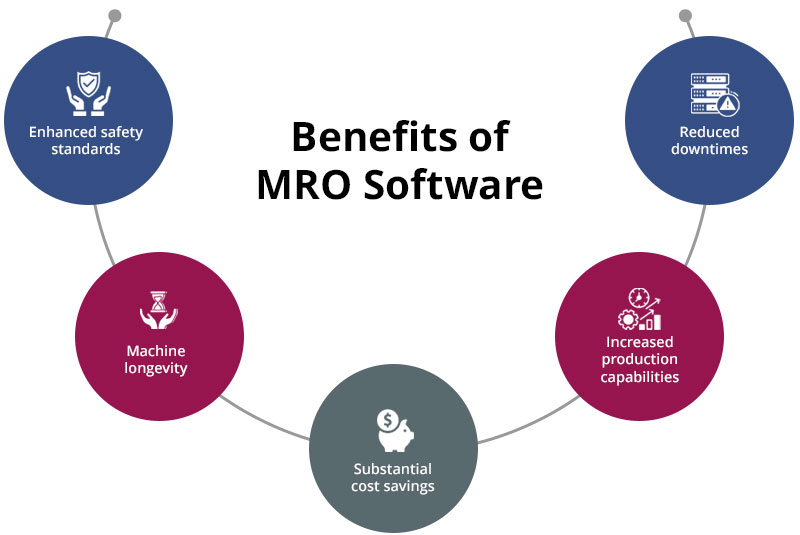

Maintenance Repair and Overhaul play a crucial importance in the modern business landscape. By adopting it, your business can benefit in several ways.

Improved Traceability: MR&O helps aviation companies around the world by improving security and traceability and streamlining the maintenance process. Overall, it helps improve the safety, transparency, and efficiency of aircraft maintenance.

Machine Safety: Periodic maintenance and repair activities not only improve the lifespan of an asset but also ensure the machine is running in a safe working condition. This helps lower the chances of accidents, potential fire & hazard situations.

Predictive Analysis: Machine faults can occur at any time and disrupt regular business activities. With an effective Maintenance Repair and Overhaul strategy, businesses can ensure continuity in production and minimize the losses incurred due to such disruptions.

Cost Savings: Downtimes not only halt business operations but also lead to the loss of potential revenue opportunities, and the trust & loyalty of the customers. With Maintenance Repair and Overhaul, businesses experience lower downtimes, leading to improved cost savings.

Anticipate Maintenance: Businesses can anticipate machine maintenance and repair in advance, and become well-prepared to take appropriate measures to minimize the potential impact on its activities and consumer expectations.

The following are the key components of Maintenance, Repair and Overhaul:

There are primarily four main types of Maintenance Repair and Overhaul. They are as follows:

Infrastructure Repair and Maintenance

Serious malfunctions and defects in the electrical system, lighting system, or drainage system of the business premises, can not only impact the business activities but also cause bodily harm to the employees or loss of life. This type specifically deals with the repair and maintenance of the infrastructure of the business premises and maintaining its integrity. It involves a wide variety of activities such as inspecting the roofing of the premises for damages and water leaks, checking the ventilation and air-conditioning system, and inspecting the integrity of the electrical system.

Production Equipment Repair and Maintenance

Production Equipment Repair and Maintenance is a type of MRO that deals with the repair and maintenance of production-specific equipment, such as bending machines, broaching machines, mixers, and so on. The goal of this MR&O is to run production equipment at optimal speed, increase production capabilities, extend the lifespan of the machinery, increase the resale value of the equipment, and lower the instances of accidents & fatalities.

Material Handling Equipment Maintenance

This involves planning and maintenance of all organizational-wide assets except the production ones. Although it is ignored by many companies, it still holds significant importance. For example, it may include various activities such as diagnosing problems regarding the shipment of materials to your plant, which is crucial for continuity in the production and delivery of the final shipment. Material Handling Equipment Maintenance helps you build robust Supply Chain Management in ERP and brings continuity to your business operations.

Tooling and Consumables

Much like the Material Handling Equipment Maintenace, the Tooling and Consumables are not directly linked to the production. It includes maintenance of seemingly minor pieces, yet crucial equipment such as masks, gloves, helmets, and eyewear. To boost the productivity and efficiency of the business operations, maintenance of the tooling and consumables holds importance.

Empower your team and elevate your results with ERP Software

The Maintenance, Repair and Overhaul Software allows your business to remain profitable and compliant, and identify & fix potential problems before they start impacting the business operations:

Prevent Safety Hazards

In an organization where large equipment and machines are used for production and other activities, malfunctions and defects can occur. Such defects in the machine can result in electric shocks, release of chemicals, or explosion, which can result in serious harm to human life. Maintenance, Repair and Overhaul (MRO) help prevent such safety hazards by using dedicated software.

Reduced Breakdowns

Not only are regular maintenance activities cost-effective, but also they boost business efficiency and productivity. In contrast, the lack of regular maintenance can degrade the overall health, performance, and lifespan of the equipment, resulting in a sooner breakdown. Such breakdowns can cost more money than periodic maintenance.

Reduce Downtimes

Downtimes can have a significant impact on businesses, including financial, consumer experience, and trust. Reducing downtimes with ERP Software helps in the continuity of business operations, and improves productivity & efficiency.

Productivity Enhancement

Regular maintenance enables businesses to fix small problems in the machine before they grow and adversely impact the machine’s health and life. A well-maintained machine results in optimal performance and productivity enhancements, both of which are necessary for the growth of the organization.

Streamline Work Orders

MRO Software helps businesses benefit from automation in various activities such as process maintenance requests, job prioritization, and managing work orders. This frees up employees from manual labor tasks and they can focus on more productive activities.

Now, let us discuss the maintenance strategies and which MRO materials they use.

Preventive Maintenance

Preventive Maintenance is a type of regular maintenance intended to lower material breakdowns & defects and maintain consistency in the material’s performance, efficiency, and safety. MRO Software helps lower unexpected repair costs and maintain consistency in the material’s performance and efficiency.

Predictive Maintenance

Predictive Maintenance is also called Condition Monitoring. It involves asset monitoring, data collection, and predicting the equipment defects or breakdowns that may occur in the future. This approach uses Industry 4.0 technologies such as Internet of Things (IoT) sensors, Machine Learning (ML), and Artificial Intelligence (AI), alongside Business Intelligence Tools.

Corrective Maintenance

It is performed whenever equipment suffers from defects, malfunctions, or damages. While Corrective Maintenance is typically unplanned, there are times when it may be planned. For example: Repairing defects with equipment that has not caused total breakdown, yet is important enough.

There are different types of Maintenance Repair and Overhaul (MRO) based on the nature of the industry of the business operations:

Oil & Gas

Given the critical nature and risks of safety hazards, oil and Gas companies have to conduct a series of safety and maintenance measures with ERP for oil and gas industry that include regular pipeline audits, and maintenance and repair of the infrastructure, to prevent fire and explosion, and ensure the safety and reliability of their infrastructure.

Healthcare

The healthcare industry uses various high-end critical medical equipment such as Computed Tomography (CT) Scanners, Magnetic Resonance Imaging (MRI) Machines, ventilators, and patient monitoring systems. They are required to regularly inspect and monitor the functioning of these critical systems.

Aviation

Aviation companies are required to regularly inspect components, maintain airworthiness, fix overheating and chemical contamination. It is only possible with aviation ERP software. According to Maintenance, Repair and Overhaul (MRO) Fundamentals and Strategies, “Most major aircraft maintenance and repair work is provided by repair shops, which carry out MRO operations for the aircraft operators. According to Pipame, 80% of MRO repair shops are small and medium enterprises.“

Manufacturing

The manufacturing businesses are periodically required to perform regular maintenance on assembly line machines. This involves planning various activities such as changing the worn-out bearings, replacing nonconforming product components, and fixing pump & valve issues using manufacturing ERP software.

Facilities Management

This involves monitoring the various electrical appliances and plumbing equipment used in the business premises. This includes inspecting the elevators, electrical wiring systems, fire safety equipment, and plumbing systems.

The Maintenance, Repair and Overhaul (MRO) products can be further divided into small categories based on their nature.

Industrial Machinery

A significant portion of maintenance repair and operations supplies fall under this category. It includes the equipment used in the manufacturing process, along with its components and spare parts. The components include motors, gearboxes, pumps, valves, and gaskets, among others.

Consumables

Consumables are part of the faculty’s inventory management system, which includes various products such as the PPE kits used in the hospitals, safety gear used in the manufacturing companies, in addition to fire alarms and gas detectors, greases, and cleaning items.

Servicing Tools

This type of Maintenance Repair and Overhaul includes all accessories used by the employees for performing their maintenance duties. It includes screwdrivers, hammers, drills, and power tools, along with any material used for landscaping purposes.

Safety Equipment

This Maintenance Repair and Overhaul includes all the safety equipment such as head & neck protection, safety glasses, hearing protection, face shield, gloves, and safety shoes, among others. These safety equipment should never be overlooked as the lack of safety measures can endanger the lives of workers, and lead to criminal legal proceedings.

Do you want to make the Maintenance Repair and Overhaul process more efficient? Besides using the best ERP software in india, here are other tips and tricks that could help:

Optimize MRO Procurement

MR&O involves a lot of materials of different sizes and categories. As a result, the standard procurement process can be costlier. Optimizing the MR&O procurement process enables the business to prioritize them by their necessity, and procure them at a reduced cost.

Vendor-managed Inventory

In Vendor-managed Inventory, the vendor is responsible for managing the company’s stock or inventory. Whenever the stock reaches a certain threshold, the vendor supplies new materials. This enables the company to focus on other operations while the vendor takes care of the inventory.

MRO Workflow Improvement

Unplanned or poorly planned Maintenance, Repair and Overhaul can lead to a waste of time & resources and increased costs. A planned Maintenance Repair and Overhaul will offer fixed assets management software that provide a comprehensive list of all organizational assets, including machinery, and equipment, and facilitate clear communication.

There is no one-size-fits-all answer. Different industries have different requirements. As such, the amount of stock of MR&O parts to hold may differ from industry to industry and company to company. However, here are some general guidelines that might be helpful:

MRO Value as Percent of PRAV

The first parameter is to compare the MR&O Value with the Plant Replacement Asset Value (PRAV). Although this method ignores the raw materials and finished goods, it gives a general idea of the value your company is spending on inventory.

Economic Order Quantity

Economic Order Quantity allows businesses to reduce inventory-specific costs (such as inventory storage costs) and find an ideal quantity of inventory to procure. This method can be used for only a specific set of your Maintenance Repair and Overhaul Materials, and not all.

Many businesses incur a substantial cost on maintenance repair and operations materials. Reducing the amount of money being spent on maintenance repair and operations can help them reduce costs and increase profit margin.

Higher Holding Costs

Having more MR&O materials in stock can result in higher holding costs. Holding costs include all types of inventory-specific costs such as the storage cost, insurance premium, and the cost of spoiled or damaged stocks.

Over-buying

Over-buying occurs when a business purchases more raw materials than it can process and sell in the market. Incorrect demand forecasting and a lack of credible information about consumer preferences can lead to over-optimism and over-buying.

Stockouts

A Stockout is said to occur when the customer’s orders for a product exceed the stock inventory, resulting in the unavailability of products for sale. Stockouts negatively affect the business through loss of revenue opportunity, poor customer experience, and negative perception of the brand.

MRO Software is a computer application that enables predictive analysis and maintenance of machinery and equipment for timely identification of faults, defects, and malfunctions, and facilitates corrective measures.

Faults, malfunctions, and defects in the machinery and equipment can lead to bodily injury, loss of human life, fire, explosion, chemical contamination, and other serious fatalities. MRO Software is a part of Computerized Maintenance Management Systems (CMMS) which centralizes maintenance information and provides one platform for centralized management.

Here are the key features that ERP implementation offers:

Generate a comprehensive maintenance schedule for each asset

Build a list of all resources required to perform the on-time maintenance

Manage service information such as pending tasks, and the serviceman assigned for each task

Automate generation of Bills of Materials (BOMs)

Get rid of data redundancy

Better manage pre-planned and ad hoc (repair) maintenance services

Manage service documents

Easily monitor KPIs and trends

Maintenance, Repair, and Overhaul (MRO) is a critical business framework intended to maximize the efficiency, functioning, and longevity of the organization’s machinery and equipment.

The repair process focuses on repairing specific machine defects for instant and cost-effective resolution (such as replacing the faulty or malfunctioning parts of the machinery). In contrast, the overhaul is a comprehensive process that restores the entire machine state to an earlier point in time (such as an optimal condition).

While MRO stand for Maintenance Repair and Overhaul, MR&O Procurement refers to the purchase of all those materials essential to maintain the machinery, equipment, and tools used for production and day-to-day business functioning. These materials are not directly used for the production activity. However, they are essential to maintain the integrity of the production machinery, equipment, and tools, and ensure continuity in the business operations.

The meaning of MRO is Maintenance, Repair, and Overhaul, which is a business strategy intended to improve the operational life and longevity of the company’s machinery and equipment. The purpose of MRO is to prevent a critical breakdown of the company’s high-value physical assets and ensure ongoing production activity at maximal efficiency.

Schedule Product Tour

"*" indicates required fields

Fill in the details below and we would be glad to help you.