Inventory Management Software

Optimize inventory levels, boost sales, and maximize customer satisfaction using dedicated Inventory Management Software

What is Inventory Management?

Inventory Management is the process of tracking, managing, and regulating the movement of stock from its procurement as raw materials till its conversion to finished goods to minimize inventory storage costs, improve customer experience, and prevent excess working capital from being tied up to the inventory.

Companies around the world strive for efficient inventory management using dedicated ERP software to reduce the instances of inventory shortages and excess stocks, both of which are detrimental to businesses. While excess inventory can lead to increased storage costs, deterioration, and waste, inventory shortage can result in lost revenue opportunities, reduced revenues, and customers turning to competitors.

What is an Inventory Management Software?

Inventory Management Software is a dedicated software that provides robust inventory tracking mechanisms, order forecasting capabilities, and concurrent monitoring of stock movements to improve inventory traceability, enhance core internal operations, promote faster decision-making, and support business growth.

Inventory Management System is widely used across businesses of all sizes and types. According to a report by Future Market Insights, the global Inventory Management Software market is sized at $2,191 Million as of 2024, and it is expected to grow at a CAGR of 13.1% till 2034. There are several factors believed to contribute to it, such as the compelling need for tools to track & forecast demand fluctuations and inventory levels.

Top 10 Best Inventory Management Software in India

1. Sage X3

Sage X3 is a versatile tool with exceptional capabilities and a powerful set of modules. It is based on an open and flexible architecture that helps you scale up your business operations. Whether you’re in the business of manufacturing, distribution, retail, food & beverage, or services, Sage X3 is an ideal solution.

Features

- Manage inbound, outbound, and intra-site stock movements

- Enhanced project visibility and streamlined collaboration

- New Inventory trends & patterns in intuitive charts, reports, and dashboards

- Filter inventory data and get detailed reports through intuitive charts & customizable dashboards

- Gain control over inventory operations and other critical business functions

- Multi-company, multi-language, and multi-currency

- Advanced quality control and sampling mechanisms

Limitations

- Customizing Sage X3 may require special knowledge, training, and support

- The implementation process may require additional time

2. Oracle NetSuite

Oracle NetSuite is a popular cloud-based ERP that offers amazing analytical capabilities, detailed insights into inventory levels and sales volume, and solid integration with other business functionalities.

Features

- Acts as the Central Source of Truth for all inventory-specific information.

- Flexible customization options to meet your growing business needs

- Identify gaps and discrepancies in the target vs actual inventory performance using KPIs

- Offers compatibility with a range of third-party applications, databases, and APIs

Limitations

- Your employees may need significant training to get hands over NetSuite

- Startups and small companies may not afford NetSuite due to higher cost

3. QuickBooks

QuickBooks is a complete solution for automating inventory management and regulating stock movement. It provides extensive stock tracking ability through serial number, Lot number, and other parameters. It keeps the inventory list up-to-date as the new stock comes in and the existing stock goes out.

Features

- Supports multi-level inventory categorization (categories and sub-categories)

- Track stock purchased from different suppliers to evaluate vendor performance

- Track near-expiring stocks and move them first to ensure timely order fulfillment & less waste

- Get automated stock alerts every time the stock reaches a certain threshold

Limitations

- It has a maximum cap on the number of active users who can simultaneously login to the system

- Handling a large transaction volume may be difficult

4. Zoho Inventory

Zoho Inventory is one of the popular GST-compliant inventory tools that helps you monitor stock flow across multiple sales channels, get a quick glimpse of the inventory, and add tax-specific information on the fly.

Features

- Group inventories into categories based on size, color, brand name, and type.

- Create Super Value Packs for your customers through creative product bundlings and manage bulk discount offers

- Generate Bill of Material (BoM) and Special Product Bundlings

- Easy inventory grouping, serial number tracking, batch inventory tracking, and product expiry tracking

Limitations

- Unlike other inventory tools, the integration options may be limited in nature

- It may offer limited scalability for some businesses

5. Sortly

Known for its simplistic interface and intuitive interface, Sortly provides a higher degree of customization than some other tools. Sortly has a mobile app too so that you can control your inventory at your fingertips.

Features

- Search & filter stock by different parameters such as Quantity, price, and additional notes

- Detailed categorization and tagging of inventory

- Multi-user access permissions to secure your organizational data against theft & data leaks

- Supports Barcode and QR Code scanning

Limitations

- Offers limited scalability as your business operations grow tremendously

- Integrating Sortly with your legacy tool can be a difficult experience

6. Sales Binder

Sales Binder is a Web-based system of inventory management that acts as the single system for organizing inventory across warehouses, retail stores, and office premises. It also offers other features such as generating Purchase Orders (POs) and getting inventory forecasts.

Features

- In-house currency conversion tools for buying and selling inventory

- Set access-based permissions to users

- Get personalized email alerts whenever the stock reaches a certain threshold

- Supports importing & exporting inventory

Limitations

- It may offer a limited feature set

- Some users reported minor technical glitches

7. Boxstorm

Are you concerned about unexpected demand spikes leading to stockouts? If so, you might want to try Boxstorm. Boxstorm helps you with a smoother and quicker order fulfillment process by maintaining a complete cloud-based inventory record. As your data is stored on the cloud, your employees can access it from the comfort of their homes, during daily commutes, or even while they are on vacation.

Features

- Manage Purchase Orders Sales Orders and inventory-specific reports

- Lower your inventory storage costs by organizing your inventory in an easy way

- Meticulously examine your inventory records using extensive auditing capabilities

- Scanning shipments and tracking inventory becomes an easier task

Limitations

- Additional training may be required to get familiar with the user interface

- The customization options available may be limited in nature

8. Odoo

Odoo is a complete solution for your unique inventory needs. It is compatible with major inventory handling methods such as First In First Out (FIFO), First Expired First Out (FEFO) and Last Expiry First Out (LEFO).

Features

- Define routes for returning, refurbishing, and re-stocking inventory

- Brings end-to-end traceability into the inventory and business operations

- Seamlessly track stock location and movement using Barcodes

- Get information about various events such as order picking, delivery, etc.

Limitations

- The reporting features may be limited compared to other rivals

- There may be minor performance issues while using Odoo

9. Square

Whether you want to automatically generate a Purchase Order (PO) every time your stock level reaches below a certain level, or you want to transfer inventory among different branches of the same company, Square has interesting features to offer.

Features

- Predict demand for inventory using Square’s forecasting capabilities

- You can create Barcodes in varying sizes and types and customize them further

- Minimize your inventory storage costs by syncing it with the market demand fluctuations

- Bulk manage & plan inventory through integration with third-party tools

Limitations

- Some advanced inventory features may not be available

- You may face some integration challenges with other apps

10. Xero

Xero is more than a basic inventory management tool. Besides keeping track of your current inventory needs, it goes further in differentiating best-selling and worst-selling inventory.

Features

- Get periodic reports about the inventory performance over a specific duration

- Supports multiple ways of inventory recording — barcode scanning, SKU numbers, Serial Numbers, RFID tags, QR Codes, and NFC tags, among others

- Add reusable text such as name field, description field, and sales tax field into invoices, quotes, and Purchase Orders (POs).

- Provides in-house tools to calculate Cost of Goods Sold (COGS) and perform Profitability Analysis

Limitations

- Supports tracking of only Finished Goods; and not Work-in-Progress and Raw Materials.

- Limited manufacturers-specific functionality

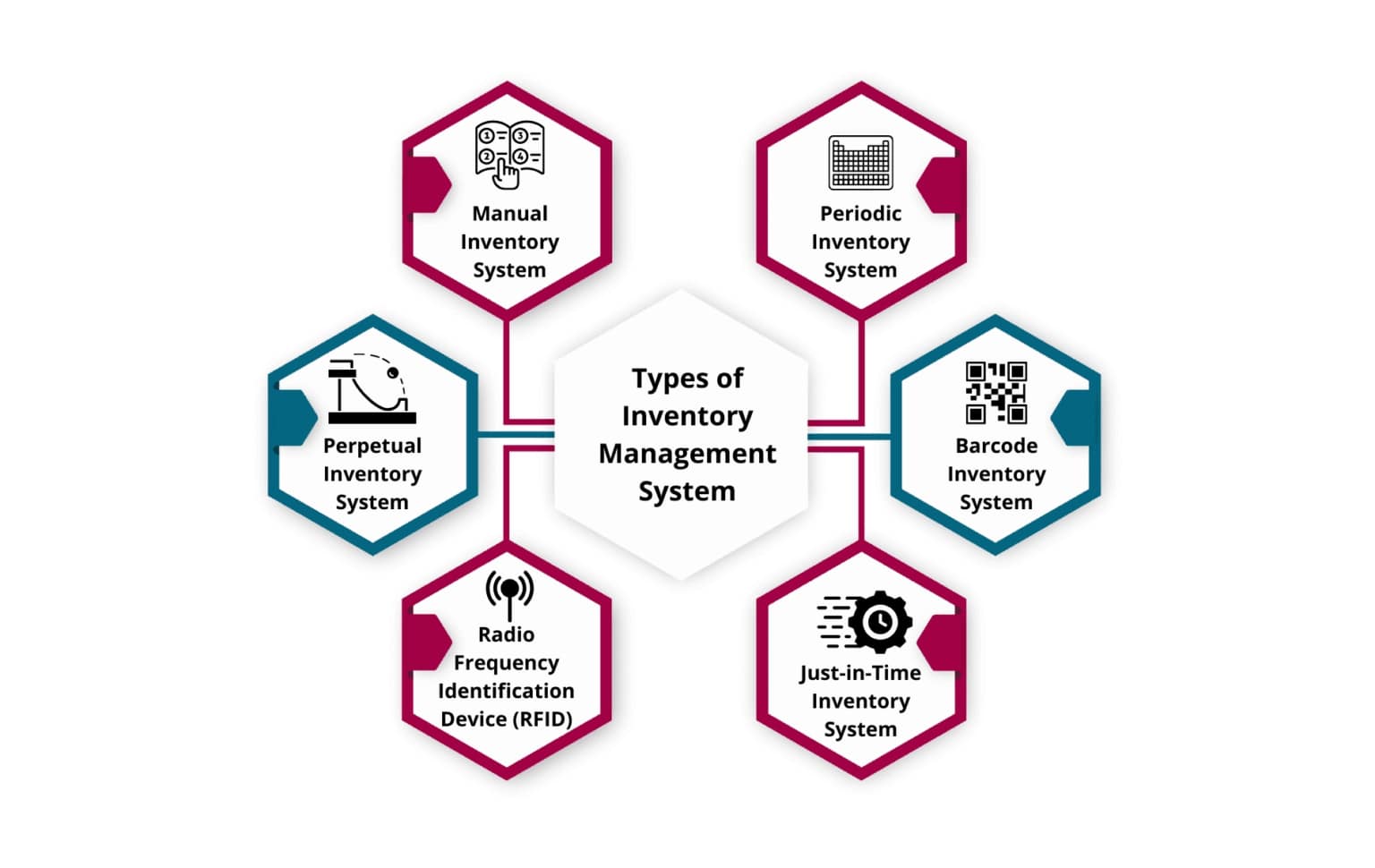

Types of Inventory Management System

The Inventory Management System can be categorized into the following types:

1. Manual Inventory System

Manual Inventory System is accomplished using spreadsheets. It is mostly popular among budget-conscious small businesses and sole proprietorships that sell one or fewer products and cannot invest in dedicated Inventory Management Software. As the new stock of inventory enters or an existing stock leaves the warehouse, your inventory management team manually updates the entries in their book or spreadsheet.

2. Periodic Inventory System

As the name describes, a Periodic Inventory System involves manually counting the stock of inventory periodically such as daily, weekly, monthly, quarterly, or yearly. The higher the frequency of counting, the better the inventory counting accuracy. Your inventory management staff uses a variety of Excel formulas to keep track of your inventory & aid decision-making.

3. Perpetual Inventory System

Perpetual Inventory System documents every purchase and sale of the stock automatically and instantaneously. This provides decision-makers with up-to-the-minute information about the current inventory levels, and changes in the inventory patterns, all without needing to re-count the inventory all the time. Besides, they can identify bottlenecks in the inventory management and take corrective measures.

4. Barcode Inventory System

Barcodes are incredibly helpful in inventory management. Companies are replacing the manual way of inventory counting with barcode scanning technology. Anyone can scan barcodes with a simple mobile or a specialized device. Barcodes bring speed & efficiency to inventory tracking and enable you to process your transactions speedily. Moreover, they reduce human errors during the entire process.

5. Radio Frequency Identification (RFID)

Radio Frequency Identification Device technology assigns an RFID Tag to each stock of inventory throughout the warehouse. Each RFID Tag can be read or rewritten using the microchips installed on it. A specialized RFID Scanner is used to track and communicate with the RFID tag-assigned stocks using radio waves.

6. Just-in-Time Inventory System

In this system of inventory management ERP, the company procures goods as and only when they are required. It aims to reduce inventory storage costs and lower the potential for human errors. While this may look like a simple approach, it requires thorough planning and analysis to identify the company’s ongoing requirements. Moreover, there is a potential risk of delaying current projects in the event of raw materials unavailability, supply chain disruptions, and adverse weather conditions.

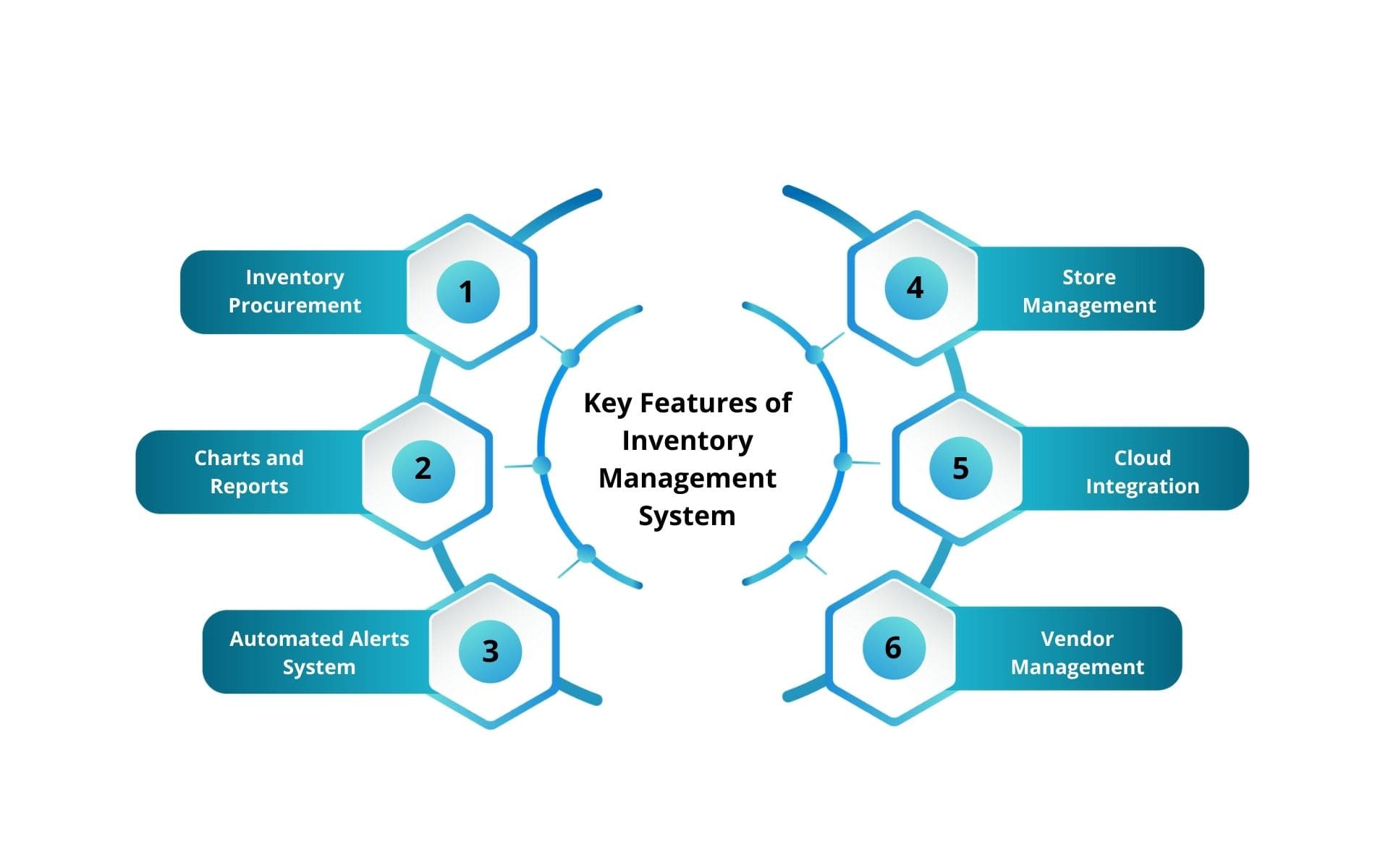

Key Features of ERP Inventory Management Software

Why are an increasing number of businesses implementing Best Inventory Management Software in India? Here are some distinct features that they offer:

1. Inventory Procurement

The procurement management system in your Inventory Management Software automates the purchase of raw materials, vendor management, vendor performance evaluation, and similar tasks. It also helps with the tracking of packages and shipments and ensures timely delivery of the orders.

2. Store Management

Do you have multiple stores located across different cities and states in India? If so, the best ERP software in India aids store management and reduces the operational complexities involved in the process.

3. Consolidated Reports

Inventory Management System provides insights into inventory handling and movement through consolidated reports, intuitive charts, and customized dashboards. This enables decision-makers to find areas requiring improvement and make strongly data-backed decisions.

4. Cloud Integration

In today’s age of information technology, the cloud has become almost synonymous with the Internet. Cloud ERP systems can be used on diverse hardware configurations. Employees and higher management can access data irrespective of where they are, and which device they use.

5. Automated Alerts System

Traditionally, inventory teams managed the company’s stock of products and performed manual supervision to ensure the company didn’t run out of stock. However, manual supervision is often prone to errors. Inventory Management System replaces it with an automated alert system that notifies the team whenever the stock reaches a certain threshold.

6. Vendor Management

Vendor Management helps your business estimate vendor performance, understand vendor capabilities, and reduce the time it takes to select an appropriate vendor and procure the right quantity of quality raw materials. Moreover, your company will benefit from reduced delays and miscommunication in the procurement process.

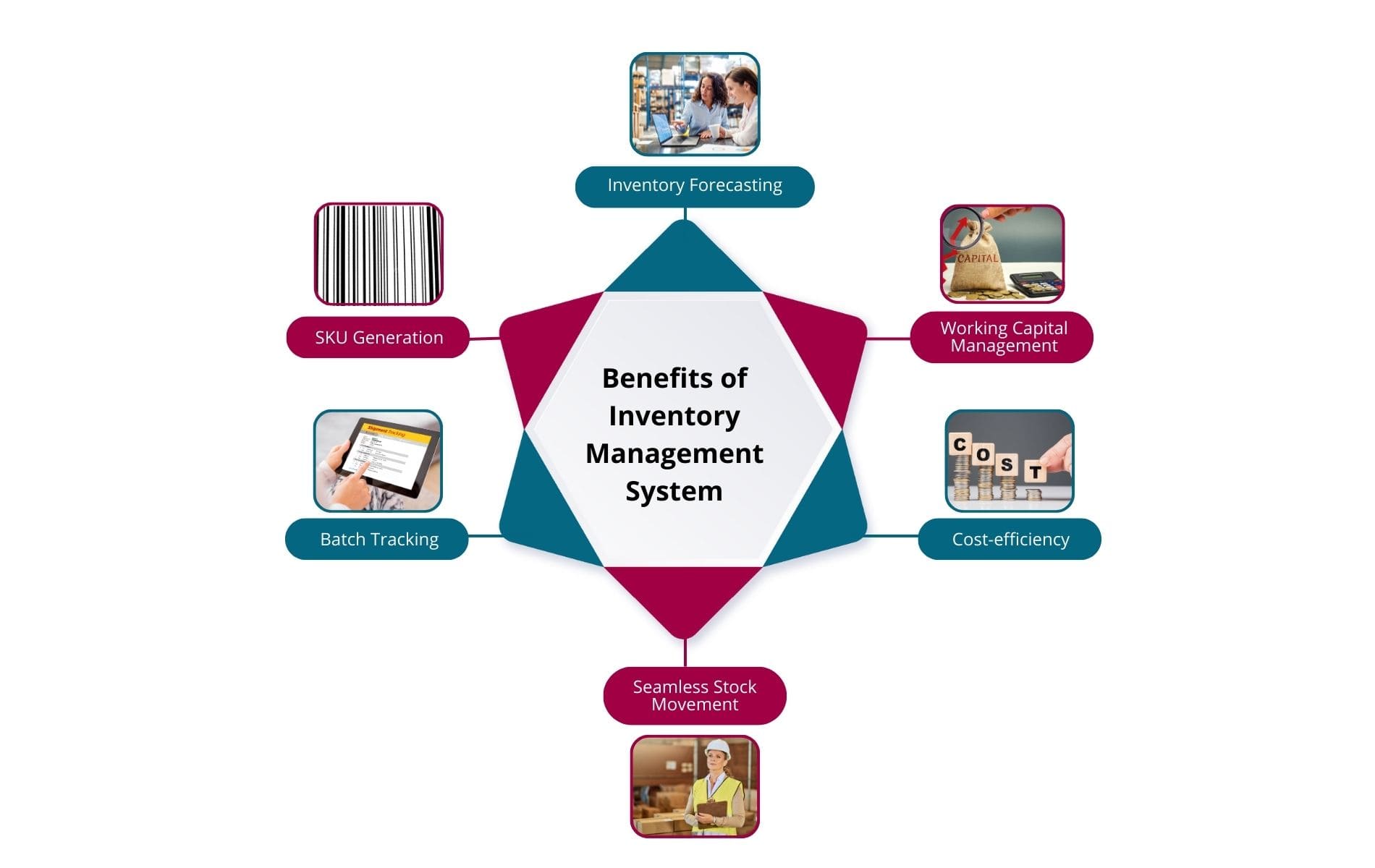

Benefits of Inventory Management System

Now, let us discuss the advantages of Inventory Management System one by one:

1. Inventory Forecasting

Inventory Management System allows better planning of inventory to prepare for sudden market changes and demand fluctuations. Accurate inventory forecasting maintains adequate inventory flow and reduces the instances of under-stocking and over-stocking.

2. SKU Generation

SKU Generation is a common process in inventory management where businesses assign a stock keeping unit to each item in the inventory, along with multiple variations of items grouped by their color, material, model, and packaging. Inventory Management System generates an array of SKUs for single products as well as batches of products to save time & improve efficiency.

3. Batch Tracking

Manufacturers often group inventory in batches by their types, models, colors, ingredients, and similar parameters. ERP Inventory Management software facilitates batch tracking of inventory using the lot number. This unique identification number is assigned to each group to reduce the complexities in the inventory recall process.

4. Seamless Movement of Stocks

One of the key benefits of ERP is that it enables the smooth movement of stock across different stores and branches to ensure timely order fulfillment. It promotes smooth communication and coordination between different teams across different branches for seamless movement of stocks.

5. Cost-efficiency

Best Inventory Management Software in India reduces manual labor work with automation, leading to a higher accuracy rate and fewer chances of errors. The increased reliance on automation saves businesses from costly stockouts.

6. Efficiently Manage Working Capital

Much like inadequate stock, excess stock can also be harmful to businesses. For example, holding a significant excess stock can lead to wastage as a portion of the working capital will be trapped in unsold stock. This money could have been used for other productive operations.

Limitations of Inventory Management System

Inventory Management System are incredibly useful to organize your inventory and bring efficiency. However, they have a few limitations.

1. Compatibility Issues

If your ERP isn’t compatible with other systems, you may miss out on many features & capabilities such as automated data synchronization, and real-time reports, among others.

2. Limited Scalability

Make sure that your new Inventory Management Software is capable of handling increasing data loads to ensure it doesn’t negatively affect your day-to-day inventory operations.

3. Limited Customizability

Does your ERP Inventory Management Software offer customizability? If not, you may not be able to fine-tune it to meet your specific business needs.

4. Higher Upfront Costs

Small businesses may not afford higher ERP cost associated with traditional On-premise solutions. However, this shouldn’t be a concern anymore with modern subscription-based cloud ERPs.

Which Industries Commonly Adopt ERP Inventory Management Software?

The inventory module in ERP is commonly used in different industries across the world. Here are some industries that are benefitting the most from ERP implementation.

1. Manufacturing Industry

The manufacturing industry heavily relies on manufacturing ERP software. It improves the level of coordination between different units and optimizes the inventory planning & management functionalities.

- Track raw materials, work-in-progress, and finished goods

- In-house inventory reporting and monitoring tools

- Schedule and optimize production activities

- Reduce waste and increase profit margins

- Ensure your company complies with the GST standards

2. Retail Industry

After manufacturing, the retail industry benefits the most from Inventory Management ERP. It’s BI Tools help retailers gain 360-degree visibility into inventory operations so that they have an adequate stock of high-demand products.

- Monitor the movement of stock across different branches and retail outlets

- Automatically monitor your inventory performance and turnover

- Ensure your inventory never reaches the minimum inventory threshold

- Forecast demand for your products & build proactive strategies to mitigate demand fluctuation risks

- Streamline payment collection and reduce cash crunch using accounts receivable automation

3. E-commerce Industry

Inventory Management System provides a deep integration with the logistics and supplier partners to facilitate better coordination, reduce complexities, and increase the business’s agility to respond to new changes.

- Faster order fulfillment and better customer satisfaction

- Automatically inform managers when the stock of a product reaches a certain level

- Harness readily available historical data to drive sales & uncover new opportunities using a sales management system

- Improve user experience and make the checkout process fast & simple

- Help decision-makers with financial planning and analysis

4. Automotive Industry

Automotive ERP eases the complexities in the automotive industry that require higher service efficiency and lower downtime.

- Track supplier orders and increase efficiency in the procurement processes

- Get a Single Source of Truth about the stock and stock movement across all channels

- Proactively adjust production plans to meet changing market dynamics

- Ensure material availability and improve the efficiency of the production cycle

- Route the orders from the fastest location to enhance customer order fulfillment

5. FMCG Industry

ERP plays a critical role in the FMCG Industry in managing perishable goods and ensuring the movement of goods across all distributions and channels.

- Track products through the expiry dates and avoid financial loss from unsold inventory

- Leverage automation and technology to transform the key business processes

- Ensure peak of supply chain efficiency using powerful supply chain management in ERP

- Analyze market trends & patterns to derive meaningful conclusions

- Adopt a quality control system throughout the manufacturing process

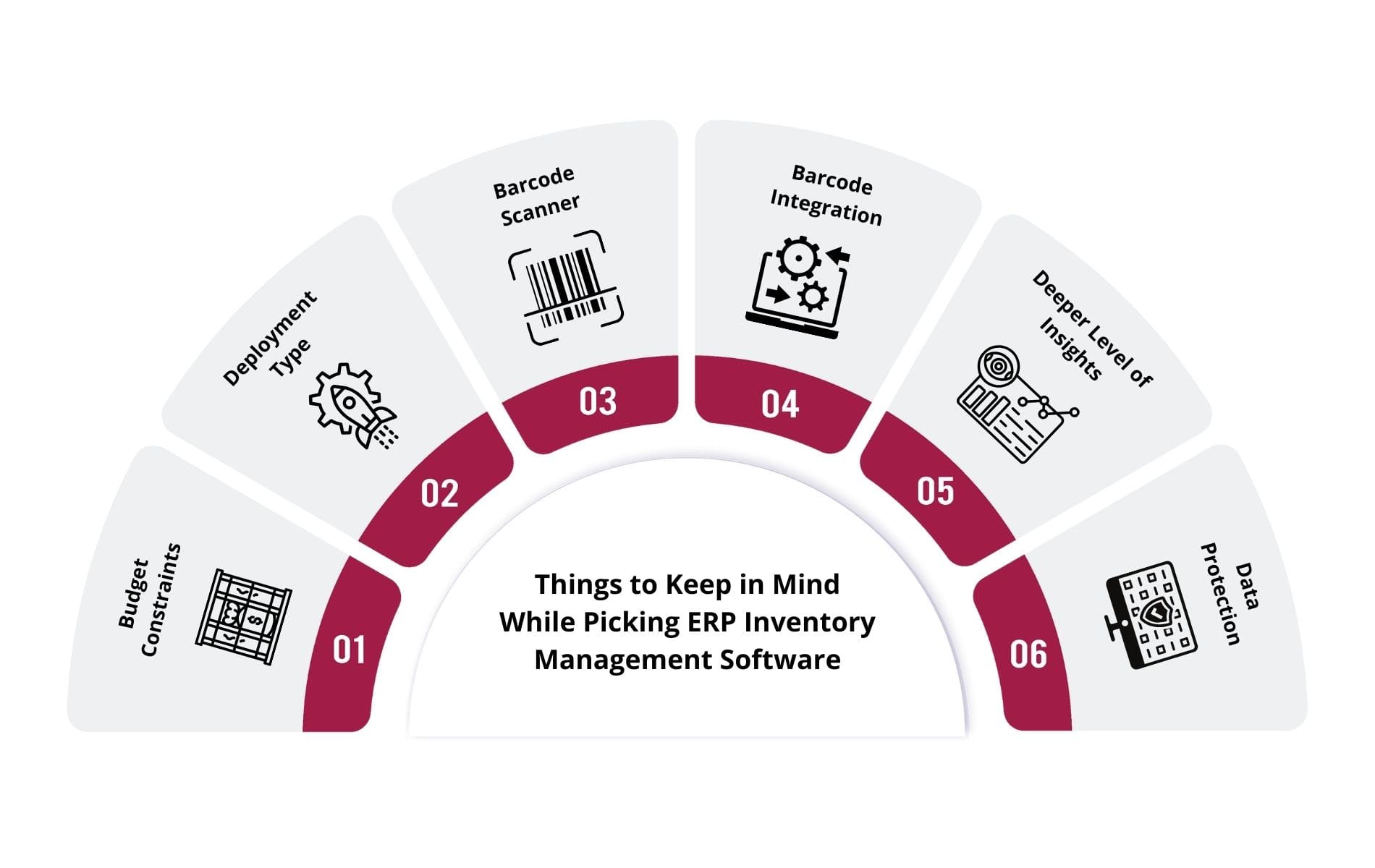

Things to Keep in Mind While Picking Inventory Management System

Inventory Management Software is a long-term investment. Here are some important factors to consider while picking the right software:

1. Budget Constraints

Every Inventory Management System varies in features and capabilities. As such, the cost of each software may differ. Make sure that your new Inventory Management System aligns with your organization’s budget. As your company expands in size, so should your Inventory Management System. It should be capable enough to support the increasing business operations and growth without data handling issues.

2. Deployment Type

Inventory Management System can be deployed in three ways — on-premise, cloud, or hybrid. Each of these types has its advantages and disadvantages. For example, in the cloud type of ERP, your vendor is responsible for maintenance & upgrade so that you don’t have to manually look after those processes. However, it may not offer as much customization as On-premise does.

3. Barcode Scanner Integration

Do you use a barcode scanner or a similar technology for inventory tracking? If so, make sure that your Inventory Management System supports integration with a barcode scanner or similar technology to ensure you will continue to maintain precise accuracy and eliminate data entry & human errors.

4. Deeper Level of Insights

Inventory Management System processes large, complex data across the organization, and converts it into simple, easy-to-understand, and intuitive charts & reports. Choose an Inventory Management System that provides a deeper level of insights to stay focused on your goals and promote strategic decision-making.

5. Data Protection

Thanks to growing consciousness about privacy and data protection, an increasing number of consumers are expecting businesses to follow the best security practices and take the lead to ensure their personal & confidential data is safe. Cloud-based Inventory Management ERP enables adherence to strict regulatory standards to ensure consumer data is safe and secure.

Latest Trends in Inventory Management Software

Here are some latest trends in Inventory Management:

1. Artificial Intelligence

Artificial Intelligence (AI) plays a key role in inventory management by properly reorganizing unstructured & fragmented data to derive meaningful insights and conclusions. With AI, businesses gain a better understanding of the latest market trends & inventory patterns to fine-tune their marketing strategy.

2. Virtual Repository

The use of a virtual repository has been a game-changer in not only inventory management but also other activities. Traditionally, businesses invested in on-premise ERP that came with major drawbacks such as hardware upgradation and huge upfront costs. The virtual repository enables businesses to rip the benefits of the cloud with a subscription-based pricing model.

3. IoT Integration

Internet of Things (IoT) devices are interconnected with each other through the medium of the Internet. The primary purpose of these devices is to gather data using their smart sensors, transmit it in real-time, and promote predictive analytics. Businesses have considerably reduced the amount of erroneous data and stockouts using IoT integration.

5 Proactive Strategies for Better Inventory Management

Now, let us discuss some of the proactive strategies for better inventory planning and management.

1. Periodic Inventory Audits

Perform manual inventory audits on a periodic basis to have a second look at the inventory levels, and examine your inventory for theft, damage, expiration, spoilage, or shrinkage. Such manual audits might take additional time, but they are essential to ensure a higher accuracy in the inventory levels.

2. Adoption of Technological Innovations

Embracing new technology and innovative strategies can help ease inventory planning and management. For example, companies across the world are adopting ERP application to automate inventory tracking, gain accuracy, and become agile to changing consumer needs.

3. Lean Manufacturing Principles

In the Traditional Manufacturing Strategy, the assembly line is perpetually on, and the stock of raw materials is available on an ongoing basis. Businesses that adopt lean manufacturing Principles in the Traditional Manufacturing Strategy are more likely to benefit from better inventory management.

4. Regular Employee Training

Employee training is one of the most important; yet often neglected strategies. Conducting regular training sessions and workshops helps your employees become well-versed and aligned toward a common objective. Ultimately, it results in higher productivity & increased profitability.

5. Risk-based Approach

Businesses suffer financial risks such as cash flow issues due to mismanaged inventory. Such risks could be avoided by increasing the business reliance on data analytics, real-time data sharing, and strongly data-backed decision-making using a dedicated warehouse management system.

Maximize Your Inventory Accuracy Using Sage X3

Inventory Management Software is a boon for various industries operating across the world. In today’s risk-riddled business world where there is a need for operational excellence and rapid sales turnover, the need for Inventory Management Software has only intensified over the years.

Sage X3 equips modern businesses with pioneering tools and unconventional capabilities to forecast & maintain optimum inventory levels, adapt to changing consumer requirements, and harness the power of data analytics & business intelligence. It will help you cut costs, stay abreast of consumer expectations, identify growth opportunities, and unlock new levels of success.

Top Industries Leveraging ERP Software

Food & Beverage

Alcohol

Pharmaceuticals

Advertising

IT Services

Furniture

Manufacturing

Auto Ancillary

Pharma Trading

Packaging

Medical Device

Chemical

Plastic

Brewery

Logistics

Automotive

Frequently Asked Questions

1. What are the Consequences of Poor Inventory Management?

Poor inventory management can affect businesses in various ways from increased cost, inefficiency, and losing market share to financial troubles. Here’s how:

Higher Storage Costs: Over-stocking inventory can lead to a more visible and immediate impact — higher inventory holding costs.

Spoil Perishable Items: Products such as fish & food with limited shelf life may risk expiration, spoiling, and deterioration, leading to lost revenues, and increased disposal costs.

Negative Brand Image: When you don’t have sufficient stock of inventory to meet customer needs, you let them down and they turn to your competitors.

Cash Flow Issues: Increased inventory costs lead to less availability of working capital. In short, the business doesn’t have enough capital to keep up its regular activities.

Less Agility: Poor inventory management makes it difficult for businesses to prepare themselves for sudden demand fluctuations & market trends.

2. What are the Use Cases of ERP Inventory Management?

Here are the common use cases of the inventory module in ERP:

E-commerce Store Management: In today’s age of digital commerce, businesses can track and manage customer orders through integration with inventory and e-commerce solutions.

Inventory Replenishment: The Inventory Management module in ERP ensures the inventory level never drops below the safety stock requirements or the minimum threshold.

Customer Relationship Management: Stockouts can degrade customer experience. You can prevent it and nurture better customer relationships using ERP Inventory.

Collaborative Decision-making: The Inventory Management module in ERP provides deeper insights to get complete & accurate knowledge for informed decision-making.

Strategic Planning: ERP Inventory Management Software integrates with legacy tools such as accounting, e-commerce, and Point-of-Sale (PoS) to support strategic planning.

3. What is Lot Tracking in Inventory Management Software?

Lot Tracking is an important aspect of Inventory Management where the company tags each batch of product with a Lot Code to search & tag products in batches. Lot Tracking is also used to identify the source of defects (such as in the case of electronic products) or contamination (in the case of food products). Sometimes, companies are forced to recall their products from the market due to significant defects, quality concerns, harm to humans, or regulatory non-compliance. Lot tracking plays a critical role throughout the entire process.

4. What is Multi-location Inventory Management?

Multi-location Inventory Management has gained significant importance in recent years. This is because many companies across the world operate in two or more countries. As such, they need robust inventory control & tracking capabilities to track stock across different locations & distributors. ERP offers them real-time tracking features and generates curated reports for strategic planning & decision-making.

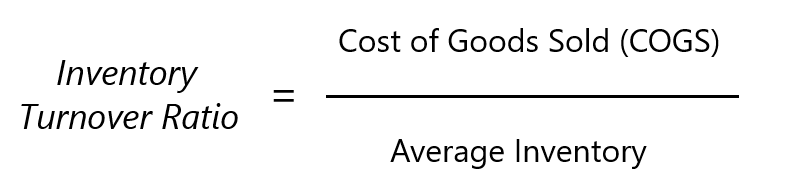

5. What is the Inventory Turnover Ratio?

Inventory Turnover Ratio is a measure of how effectively a company is using its inventory. It is popularly used by retail outlets to identify inventory-specific challenges such as excess or inadequate inventory. It is calculated by dividing the Cost of Goods Sold (COGS) by the Average Value of the Inventory at a given period of time. A higher Inventory Turnover Ratio denotes higher sales or an insufficient inventory threshold. In contrast, a lower Inventory Turnover Ratio denotes less sales or excess inventory levels.

Here’s the formula to calculate the Inventory Turnover Ratio:

Schedule Product Tour

"*" indicates required fields