Supply Chain Management Software (SCM)

What is Supply Chain Management?

Supply Chain Management encompasses all the processes involved in the supply chain operations such as production planning & scheduling, product shipment, returns management, and distribution & logistics, in addition to planning, movement, and storage of all types of inventory (whether raw materials, work-in-process, or finished goods).

Supply Chain Management is a multifaceted process of procuring raw materials, converting them into finished goods, and then delivering them to the final consumer. It relies on a complex network of organizations such as vendors, manufacturers, wholesalers, retailers, and distributors. Today, businesses rely on sophisticated supply chain networks to cater to the needs of a wider range of customers.

What is Supply Chain Management Software?

Supply Chain Management Software is a multi-functional solution that allows businesses to manage the entire flow of products and information from the product development stage to actual order fulfillment through an extensible set of tools for production planning, demand planning, inventory forecasting, and transportation management.

ERP Software empowers businesses with powerful production planning, inventory & warehouse management, and order tracking capabilities. This allows businesses to benefit from predictive insights, and data-backed decision-making while freeing up employee time & organizational resources for higher strategic endeavors.

According to a news report in the Financial Express, India is emerging as a reliable alternate destination for manufacturers and supply chain diversification across the world. Indian supply chain market was estimated at USD 3,421.17 Million in 2023. It is expected to grow to USD 6,433.24 Million at a Compound Annual Growth Rate (CAGR) of 11.1% by 2030.

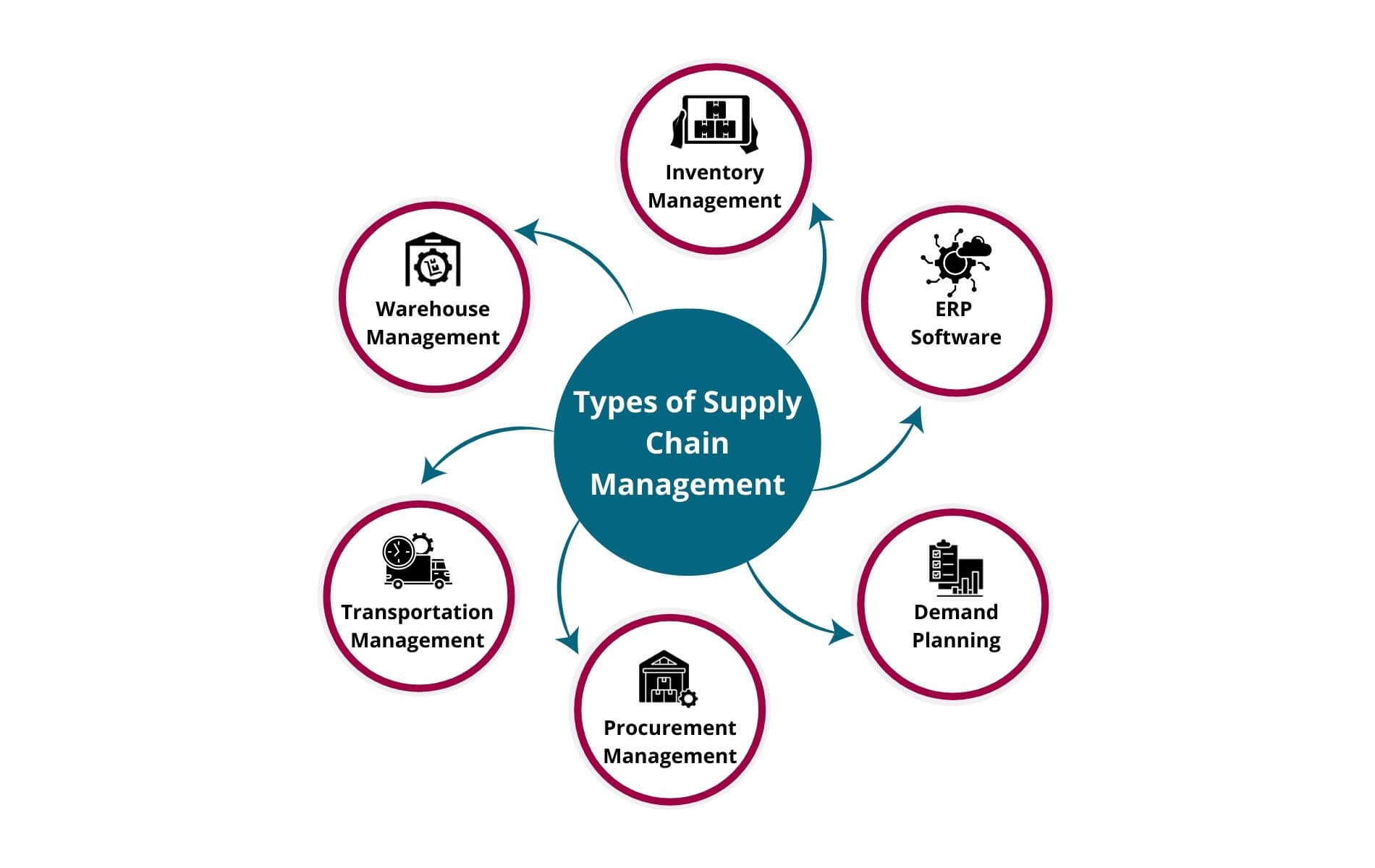

Types of Supply Chain Management Software

Here are the key types of the Supply Chain Management Software:

1. Inventory Management

The inventory management system helps businesses keep optimum inventory levels and ensure there is enough stock of inventory to fulfill customer demands. It also automates various inventory-specific activities such as tracking and managing inventory, and inventory planning & forecasting.

2. Warehouse Management

The warehouse management system keeps a detailed track of the warehouse stock items such as their quantity, storage location, and their movement to/ from the warehouse. The primary objective of using this type of ERP SCM is to better organize the warehouse stock, reduce waste, and improve efficiency.

3. Transportation Management

The Transportation Management type of the ERP System in Supply Chain Management deals with the transportation of the goods such as tracking the shipment and choosing the best transportation method. ERP system in Supply Chain Management enables businesses to optimize their shipping routes, reduce transportation costs, and speed up the transportation process.

4. Procurement Management

As the name describes, the procurement management system is aimed to automate the procurement process and improve the business and supplier relationship. It automates various procurement tasks such as gathering supplier-specific data, automating Purchase Orders (POs), and evaluating supplier performance to reduce manual labor work & improve efficiency.

5. Demand Planning

Demand Planning is a crucial Supply Chain Management Solution (SCM Software). It plays an important part in anticipating the demand for the company’s products by analyzing historical sales data and finding trends & patterns. By accurately forecasting market trends & patterns, the company will be in a better position to efficiently schedule its production activity.

6. Enterprise Resource Planning

ERP is an all-comprehensive and multi-functional tool that contains a robust array of features and capabilities including all those mentioned above. It consolidates data from different sources across the organization and provides a unified view of the business operations for quick & informed decision-making.

Distinct Features of Supply Chain Management Software

Here are the distinct features of the ERP for Supply Chain Management:

1. Data Consolidation

SCM Software consolidates data from different departments across the organization and acts as the centralized system of information management. With a familiar user interface and similar experience, it brings standardization throughout different processes.

2. Process Optimization

Another benefit of the ERP Supply Chain Management module is that it reduces manual work and eliminates discrepancies. It unlocks the full potential of your employees and streamlines the decision-making process of the higher management.

3. Cloud System

ERP for Supply Chain Management stores your data on the cloud so that you can access it no matter where you are, and which device you use. Besides, it saves the organization from the hassle of paying upfront costs for license charges and hardware upgrades.

4. Analytical Reports

ERP for Supply Chain Management unifies data and brings transparency and visibility across different processes. It provides a holistic view of the organizational information through customized dashboards and interactive charts & reports. It helps decision-makers evaluate the critical aspects and measure performance to make timely & informed strategic decisions.

5. Compliance Management

Businesses have to comply with regulatory bodies to avoid fines, penalties, and legal consequences. However, regulatory compliance is not a straightforward process. Supply Chain Management Software helps businesses actively monitor new regulatory requirements, and make compliance a less complex and less painful process.

6. Project Planning

Throughout the journey of a business, business planning and analysis are vital for its success. One of the core features of Supply Chain Management Tools is that they facilitate project planning and seamless monitoring and execution of different projects. Decision-makers can identify bottlenecks and take corrective measures.

5 Essential Phases of Supply Chain Management in ERP

The following are the phases of the Supply Chain Management in ERP:

1. Demand Forecasting

The first step in Supply Chain Management SCM is to forecast the demand for the company’s products and services through various ways from analysis of historical data, and seasonal analysis to identification of trends & patterns. Demand forecasting enables businesses to allocate adequate budgets that align with the organizational goals and objectives.

2. Supplier Research

Supplier research is an important step before the production activity takes place. It starts from researching the suppliers available in the market, evaluating the quality of their products, negotiating with the suppliers to get better prices, and initiating the actual contracts for the purchase of raw materials.

3. Production Activity

Production is an activity of converting raw materials into finished goods. In order to ensure the production of quality goods, the company needs to employ various quality control mechanisms at various stages and allocate sufficient resources comprising human labor, machinery & equipment, and raw materials.

4. Market Distribution

The next step is to distribute the manufactured products into the market. It involves considering various important factors such as the transportation cost, time & speed of the delivery, and target customer base. The product is finally distributed to different wholesalers or retailers across the targeted market.

5. Returns Management (Reverse Logistics)

Customers may return their products when they are dissatisfied with them, or receive wrong or defective products. The Returns Management phase involves arranging pickup & transportation to the warehouse. Since higher returns affect the profit margin of the company, they need to take a series of measures to minimize returns such as implementing stricter quality control and drafting a clear Returns Policy.

Benefits of Supply Chain Management in ERP

The following are the benefits of the Supply Chain Management in ERP:

1. Enhanced Inventory Management

ERP for Supply Chain Management provides a centralized system of inventory management that allows your business to track and manage the inventory in real time. For example, if you’re running a large food business, ERP for food industry will provide you with an inventory replenishment system to generate automated Purchase Orders to the right vendor every time your stock level reaches a certain threshold.

2. Optimize Supply Chain

Other ERP benefits include free flow of information and transparency across the supply chain operations. The ERP SCM reduces manual labor work in the supply chain process and lowers data silos. It automates the vendor selection process and brings efficiency to the entire process.

3. Match Supply with Demand

In today’s competitive business environment, there is a growing need to meet the changing demand fluctuations to ensure continuity in revenue. If you’re a vehicle manufacturer, ERP for automotive industry will help you standardize the key internal processes, assign vehicles to customer orders, and help you with accurate order fulfillment through analytical and forecasting tools.

4. Freight Tracking

To better understand, let us take an example of a manufacturing firm. The manufacturing ERP software lets manufacturers track the movement of goods from their warehouse till the final delivery to the customers. A reputed ERP for Supply Chain Management provides various analytical reports, and customized dashboards to help you identify areas of improvement, and take corrective measures to prevent business disruptions.

5. Stricter Regulatory Compliance

Businesses operating in multiple jurisdictions often find it difficult to stay compliant with ever-changing and complex regulatory requirements. One of the essential benefits of ERP SCM is that it helps your company stay compliant with the regulatory requirements to avoid fines, penalties, and legal proceedings.

6. Supplier Collaboration

Supply Chain Management in ERP keeps a track record of all suppliers and increases trust & collaboration. It lets you track vendor performance, and issue Purchase Orders (POs). The invoice management system eliminates manual invoicing efforts by automating invoice generation. Thanks to Supply Chain Management Tools, the business benefits from increased efficiency in the supply chain process, and reduced manual errors.

Limitations of Supply Chain Management Software

1. Erroneous Demand Forecasting

As the demand is influenced by dozens of factors such as the availability of substitutes & price elasticity, there is always a small risk of unexpected sharp fluctuations, leading to inaccurate forecasts.

2. Implementation Hurdles

A lack of planning, research, and training can make the ERP System in Supply Chain Management a difficult and time-consuming implementation.

3. Customization Challenges

If your Supply Chain Management Software offers limited customizability, you may not be able to reap the best benefits.

4. Compatibility Issues

If you don’t choose the right Supply Chain Management Software, there’s a possibility of compatibility issues while importing and exporting data with third-party legacy applications.

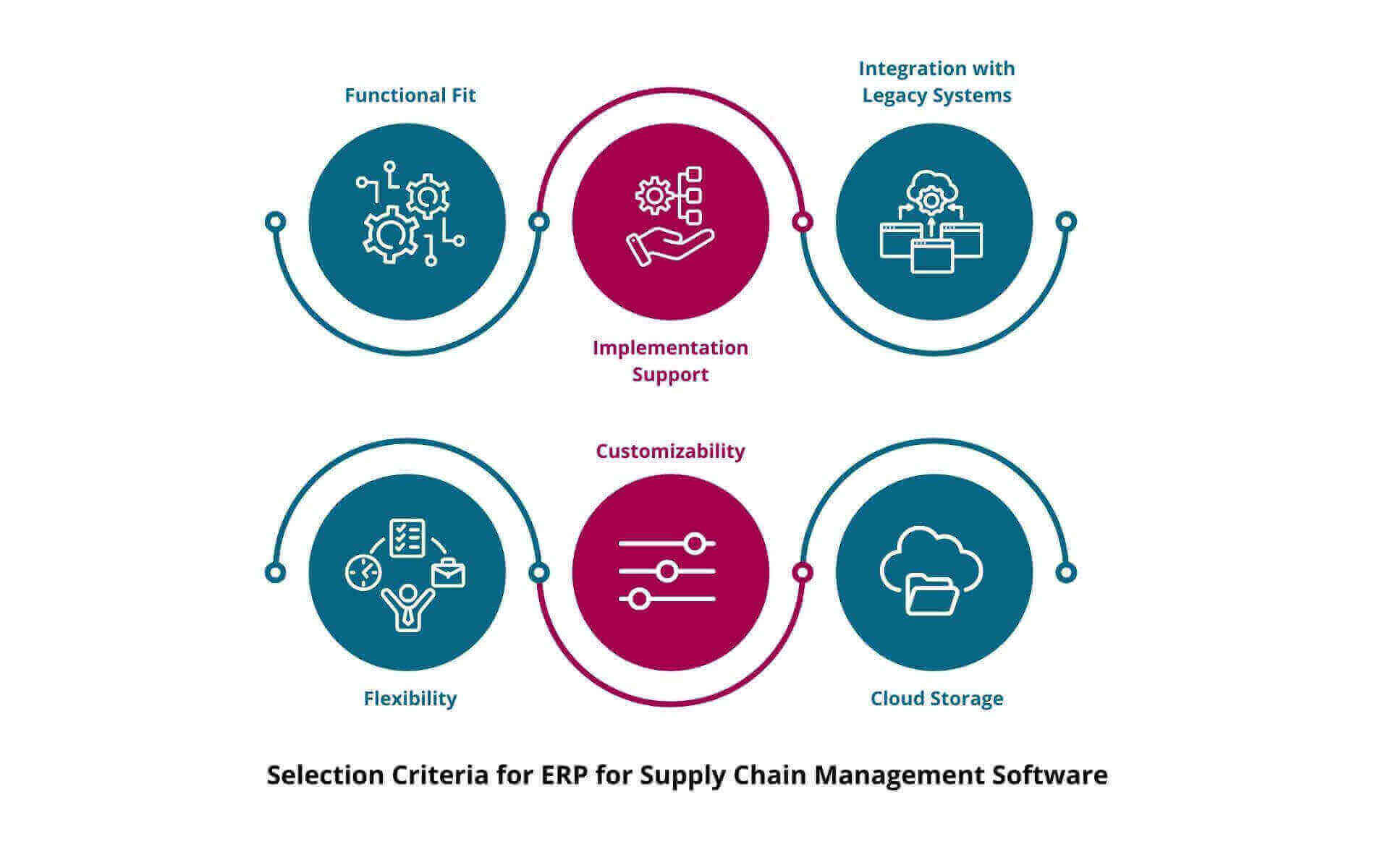

Key Factors to Consider While Selecting an ERP for Supply Chain Management

Here are some key factors to take into consideration while selecting an ERP for Supply Chain Management:

1. Functional Fit

Your Supply Chain Management Tools must fit the unique needs and requirements of your company and industry. Before choosing an SCM Software, make sure that your ERP vendor has a deep understanding of your unique business needs and industry requirements. Otherwise, your investment in the SCM Software may not yield the desired results or cause disruptions in the business activities.

2. Implementation Support

ERP implementation is a complex process that may take both time and require patience. This is why, it’s important to check out whether your new vendor provides extensive training and technical support needed throughout the entire implementation phase, and even after the implementation is completed. Ignoring this one of the most critical factors can make the entire implementation process slow & tedious, and prone to business disruptions.

3. Integration with Legacy Systems

Some businesses use various tools for different purposes such as a CRM for sales & customer support, accounting software for financial management, and so on. Make sure that your ERP application supports integration with all the existing systems, in case you want to retain them. For example, a furniture manufacturer should opt for ERP for furniture manufacturing that integrates with his existing systems to ensure he can seamlessly transfer data in real-time.

4. Expansion Capability

Your ERP SCM should be scalable enough to support your growing organizational requirements. For example, as your business expands in size, your system should be in a position to handle the larger dataset without encountering sluggishness. The best ERP software in India ensures continuity in business operations without disruptions.

5. Offers Customizability

Make sure that your new ERP Supply Chain Management module offers a higher degree of customizability so that you can ensure that it aligns with your unique company and industry requirements, and follows the best practices. The higher the customizability an ERP offers, the better it is. However, customizability should not be the only factor to consider.

6. Cloud Accessibility

In today’s age of cloud, businesses are leveraging the cloud ERP to store and access business data. ERP for Supply Chain Management should support integration with the cloud systems. This will help you lower your ERP cost by avoiding large upfront fees associated with traditional systems and leveraging cost-effective solutions.

Supply Chain Management vs Operations Management

Boosting Supply Chain Efficiency with Sage X3

Supply Chain Management Software helps you manage every aspect of the supply chain operation, break-down silos, improve the logistics operation, and elevate your business potential. It contains a set of tools and modules that give you control over an increasingly complex supply chain process.

Sage X3 is an indispensable solution that empowers your business with tracking the movement of goods, regulating sales channels, optimizing supply chain routes, and getting a 360-degree view of the supply chain network. It acts as the centralized hub of information management to help you unlock new business potential and tackle complex supply chain challenges.

Top Industries Leveraging ERP Software

Food & Beverage

Alcohol

Pharmaceuticals

Advertising

IT Services

Furniture

Manufacturing

Auto Ancillary

Pharma Trading

Packaging

Medical Device

Chemical

Plastic

Brewery

Logistics

Automotive

Frequently Asked Questions

1. What are the Key Challenges Faced During Supply Chain Operations?

2. How Does ERP for Supply Chain Management Support Demand Forecasting?

ERP for Supply Chain Management provides sophisticated algorithms and powerful tools such as a sales management system, to predict demand for organizational goods and services. It aggregates historical data from different sources and uncovers trends & patterns. With a high degree of accuracy, businesses can uncover new opportunities, fine-tune their strategies, and mitigate risks.

3. How Does SCM Software Contribute to Operational Cost-efficiency?

The Supply Chain Management Software coordinates manufacturing processes, organizational data, activities, processes, and financial resources to ensure the optimal flow of goods and services. It plays a critical part in helping businesses maintain optimum inventory levels, reduce stock-outs, and lower storage costs. Furthermore, the asset management feature in the SCM Software keeps a complete track of the organizational assets. It assigns a unique tag to each asset to easily tag them and avoid instances of asset misplacements or assets being stolen.

4. How Does ERP for Supply Chain Management Improve Supplier Relationship?

ERP for Supply Chain Management streamlines the process of purchasing raw materials from suppliers and replacing manual Purchase Orders with automation. It helps your company nurture longer supplier relationships, get better deals, lower procurement costs, and achieve profit maximization.

5. What are Some Challenges Faced During the SCM Software Implementation?

SCM Software plays a vital role in identifying demand for your company’s products. However, this data is not necessarily 100% accurate. Moreover, the technological integration of Supply Chain Management in ERP can take additional time than anticipated. Some of your employees may also oppose the adoption of modern technological tools. Your time and patience are necessary throughout the entire process.

6. What is Green Supply Chain Management?

Green Supply Chain Management is a concept dedicated to preventing harm to the environment or reducing the intensity of the harm. It involves taking a series of measures to promote sustainable practices intended to reduce waste, global warming, and deforestation. As part of Global Supply Chain Management, a company replaces traditional packaging with environment-friendly packaging and reduces its reliance on the use of plastic material.

Schedule Product Tour

"*" indicates required fields