What is Warehouse Management System (WMS)

What is a Warehouse Management Software (WMS)?

A Warehouse Management System (WMS) is an integrated solution within ERP software that allows your business to administer and control various warehouse processes from the time of their procurement as raw materials till their conversion & distribution as finished goods to facilitate better inventory tracking, and improve the efficiency of the warehouse operations and order fulfillment to the final customer.

The Warehouse Management System not only serves as a repository of extensive business information but also automates a multitude of warehouse operations to ensure there is no slowness or disruption in the supply chain process. It provides up-to-the-minute insights on how quickly inventory is collected, located, packaged, and sold in the market so that decision-makers can take corrective measures.

What are the Features of a Warehouse Management System?

1. Batch Management

A WMS System plays a vital role in increasing the efficiency of the customer’s inventory handling. It allows businesses to batch manage the stock of inventory based on their unique characteristics such as color, size, type, ingredients, and usability. It reduces the time required to locate and fulfill customer orders.

2. Stock Rotation

Stock rotation is an effective technique used to fight stock obsolescence or expiration. WMS Software enables businesses to perform stock rotation by prioritizing the stock distribution that is expiring earlier. It is extremely important for businesses that deal with perishable products such as food, dairy products, fish, eggs, cooked foods, and so on.

3. Returns Management

In today’s highly competitive world, businesses have to provide a seamless Returns Policy to ensure customers get what they have paid for, and they don’t hold negative perceptions about the brand or product. A Warehouse Management System (WMS) automates various processes in the returns from restocking, and reverse logistics, to managing loyalty points.

4. Product Shipment Management

A Warehouse Management System (WMS) streamlines various processes in product shipment from invoice generation to automated shipment notifications. Furthermore, before a shipment is shipped, it drafts and automatically sends a Bill of Landing, which is required to prove the ownership of the cargo.

5. Labor Management

Another important feature of the Warehouse Management System is its ability to monitor labor performance and allow decision-makers to evaluate it. They can use various Key Performance Indicators (KPIs) to assess labor performance and make decisions to improve their productivity, reduce inefficiency, and ensure smooth continuity in the warehouse operations.

6. Mobile Integration

Sage X3, A Warehouse Management System enables your employees from scanning scan barcodes, access historical data, and perform quality inspections to check inbound trailer information, everything using their mobiles. The employee’s mobile app is connected to a centralized cloud server to ensure the transmission of up-to-date and accurate information.

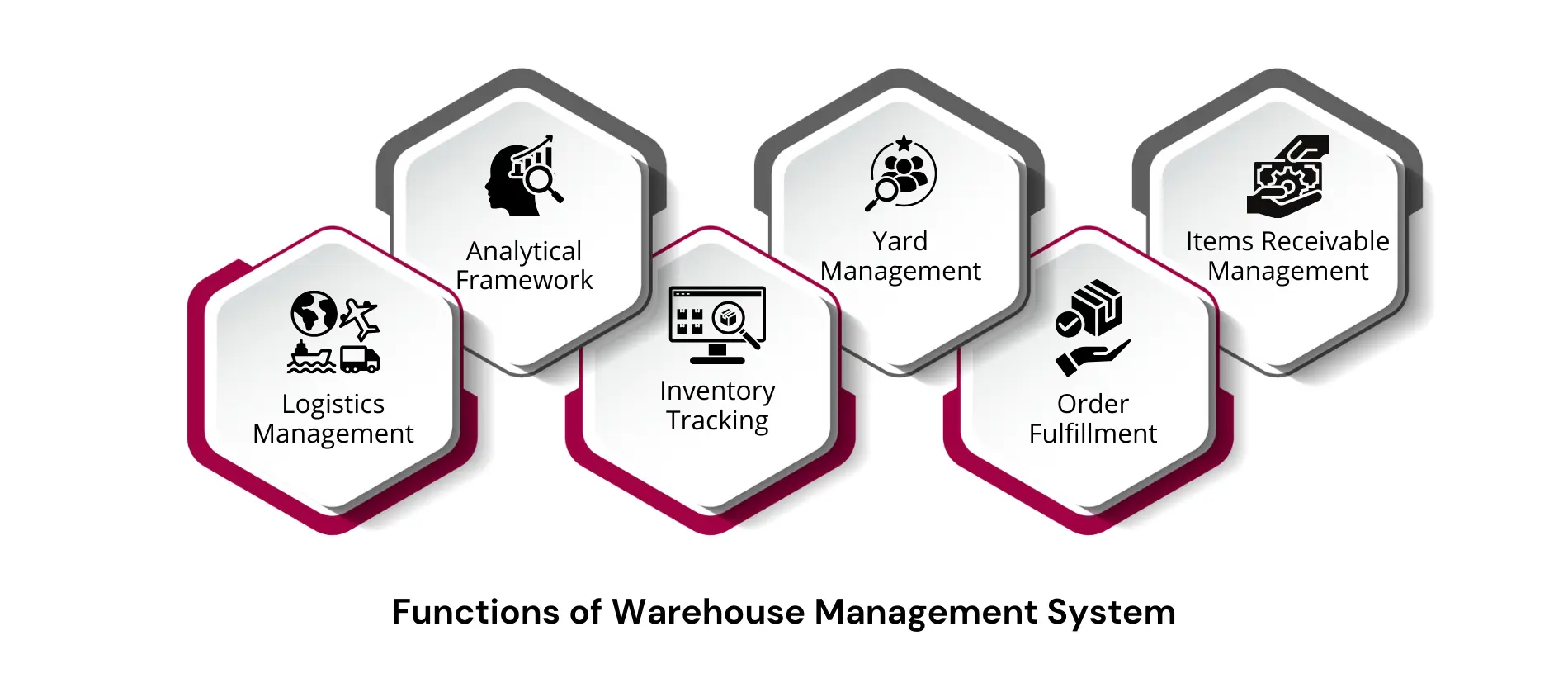

What are the Functions of a Warehouse Management System?

1. Analytical Framework

WMS Software transforms the warehouse management process by replacing data entry & manual work with automation. It consolidates data from different sources and speeds up the data retrieval and processing. It helps decision-makers with intuitive charts, reports, and customized dashboards to make quick decisions pertaining to warehouse operations.

2. Logistics Management

Extended warehouse management contains specialized modules that are dedicated to shipping, transportation, and logistics management. It facilitates streamlining various logistics and shipping activities such as the generation of order invoices, Bill of Landing, and the list of packaged items. Ultimately, the business benefits from improved traceability and coordination, lower shipping and transportation costs, and faster package arrival.

3. Inventory Tracking

Warehouse Management Software keeps a detailed record of the inventory in transit and storage and makes it easier to track, manage, and forecast inventory. It assigns a unique number to each inventory and provides integration with Barcode & other technologies. Employees can also perform batch tracking using the Batch Number assigned to each group of inventory.

4. Yard Management

Warehouse Management Software plays a critical role in the Yard & Dock Management process. It builds a Digital Map of the yard where businesses can track the location of trailers and improve coordination. It optimizes inbound and outbound freight, schedules yard activities, improves loading efficiency, and enables comparison between receiving scans & current sales orders.

5. Order Fulfilment

Order fulfillment is one of the core aspects of the business activities. Extended Warehouse Management brings down the time and complexity of the order fulfillment process with the help of technology and innovation such as Pick-to-Light, Pick-to-Voice, Radio Frequency (RF), and scanners, all of which collectively transform the entire process.

6. Items Receivables Management

A Warehouse Management System empowers businesses with efficiency gains in the items receivables, items processing, and storage processes. It improves the warehouse workflow by enabling businesses to eliminate the human errors associated with manual data entry and making effective use of Radio Frequency Identification Devices (RFID) and similar devices.

What are the Benefits of Deploying a Warehouse Management Software?

An increasing number of businesses are deploying a Warehouse Management System to unlock the following benefits:

1. Expedite Movement of Goods

Warehouse Management System empowers businesses with automation to improve their volume handling capability and boost the movement of goods. Business owners can get a 360-degree view of their business processes to identify discrepancies and make strategic decisions to overcome them. Moreover, the use of automation reduces human errors and brings in accuracy.

2. Automated Replenishment System

WMS Software keeps a complete record of product expiries so that you can sell sooner-expiring products first. The “First Expired, First Out (FEFO)” method lets you re-arrange your inventory in such a way that you will save your warehouse storage space and lower the time it takes to locate your inventory.

3. Reduce Inventory Misplacement

The use of a Warehouse Management System aids with inventory planning and forecasting, WMS System provides real-time tracking of the inventory movement and lowers the instances of misplacement & miscalculation. Not only that, decision-makers can understand how certain products are performing and use powerful forecasting tools to make accurate forecasts.

4. Limit Warehouse Costs

We all know the manufacturing cost, but we often neglect the warehouse storage costs. Businesses incur a significant amount on the rental of the warehouse premises, stock maintenance, labor, and taxes. Deploying a Warehouse Management System (WMS) allows you to maintain optimum inventory levels, reduce over-stocking, and save the cost of warehouse operations.

5. Inventory Traceability

Warehouse Management Software keeps a complete record of the inventory along with its Serial Number, Batch Code, and Lot Number, and provides decision-makers with comprehensive reports and analysis. It groups inventory by its distinct characteristics such as color, size, and ingredients. Not only does it reduce a lot of manual work, but also paves the path for aggregate planning and forecasting of inventory.

6. Efficiency in Billing Operations

A Warehouse Management System (WMS) comes with an accounts receivable automation which reduces human errors, miscommunications, and time delays in the billing process. It makes the billing process faster, more accurate, and transparent, thereby increasing customer trust, ensuring stricter regulatory compliance, and seamless order fulfillment.

Upgrade Your Business DNA with Sage X3

Empower your team and elevate your results with ERP Software

Key Types of a Warehouse Management System (WMS)

Warehouse Management System (WMS) is categorized into different types based on its nature and functionality:

1. Standalone Warehouse Management Software

A Standalone Warehouse Management Software is an independent tool that is not a part of any other existing systems. It assists businesses with inventory tracking and management, order retrieval, labor management, picking and shipping management, among others. It is cost-effective, which makes it an attractive choice for small and medium-sized organizations with limited budgets. However, a major drawback with this type of WMS Software is that it often lacks integration with third-party tools.

2. ERP-integrated WMS System

Enterprise Resource Planning (ERP) is a tailored solution that empowers businesses with automation and assists decision-makers with business planning, data analysis, and forecasting features. A WMS System can be an integral module of an ERP application. Unlike a standalone solution, it provides seamless data sharing, consolidation of data from different sources, and deep integration with other ERP modules. Decision-makers can gain a 360-degree view of business operations using comprehensive charts, reports, and customized dashboards, and access to powerful business intelligence tools.

3. Cloud WMS System

Cloud WMS System is a type of Warehouse Management System installed on the vendor’s servers, rather than the company’s infrastructure. As the cloud ERP doesn’t require upgrading the hardware infrastructure, it is cost-effective, lightweight, scalable, and flexible with no upfront costs. Apart from the ERP cost, it offers your employees access to its data from any device (such as a computer, tablet, or mobile) or location without needing to be physically present in the office. Cloud WMS System is often available as a Software-as-a-Service (“SaaS”) subscription.

4. Supply Chain WMS Software

The Supply Chain Management Software is a specialized tool that offers deep integration with other business departments and up-to-the-minute insights into warehouse management and supply chain operations. Implementing a Supply Chain WMS Software allows businesses to reduce their operational time & costs, enhance customer support, and timely fulfill all customer orders. Adopting such a dedicated solution will streamline your business operations and make it agile to changing market conditions.

5 Principles of Extended Warehouse Management

The following principles of Extended Warehouse Management help bring efficiency to warehouse operations and benefit from cost reduction:

1. Ideal Inventory Levels

A business must maintain ideal inventory levels to mitigate the risks of over-stocking and under-stocking. Over-stocking arises when a business maintains more than required inventory levels, leading to higher inventory storage & operation charges, and increased operational time. In contrast, understocking arises due to inventory shortage, leading to missed opportunities and a negative public perception of the brand. For better inventory planning, it is important to choose the most appropriate inventory valuation methods.

2. Faster Transaction Processing

The second principle of Extended Warehouse Management is to speed up the transaction processing phase. It can be accomplished by using a dedicated sales management system to process sales orders electronically, extract customer information, and digitize the manual time-consuming invoice-generation process. By eliminating manual work, you can achieve time & cost efficiency and maintain consistency in the process.

3. Regular Employee Training

Employees working in the warehouse management department are the backbone of the warehouse operations. Conduct regular employee training, and maintain adequate hygiene & working conditions to ensure they are productive and efficient. When employees are highly motivated, it can positively reflect on their work performance.

4. Process Optimization

Process Optimization involves analyzing the existing processes, and tweaking them to increase the performance and fix inefficiencies. Decision-makers can analyze existing business processes, thoroughly analyze & fix discrepancies, and perform capacity planning for improved resource utilization. Optimizing the warehouse processes can benefit in different ways from reduced waste, increased coordination, and cost-efficiency, to lower complexities.

5. Regular Performance Audits

Regular performance audits are essential to detect inefficiency in warehouse management and take corrective measures to improve the data workflow. Businesses can perform a detailed 360-degree analysis of the warehouse operations to make sure that their staff, resources, and materials are aligned to meet their goals.

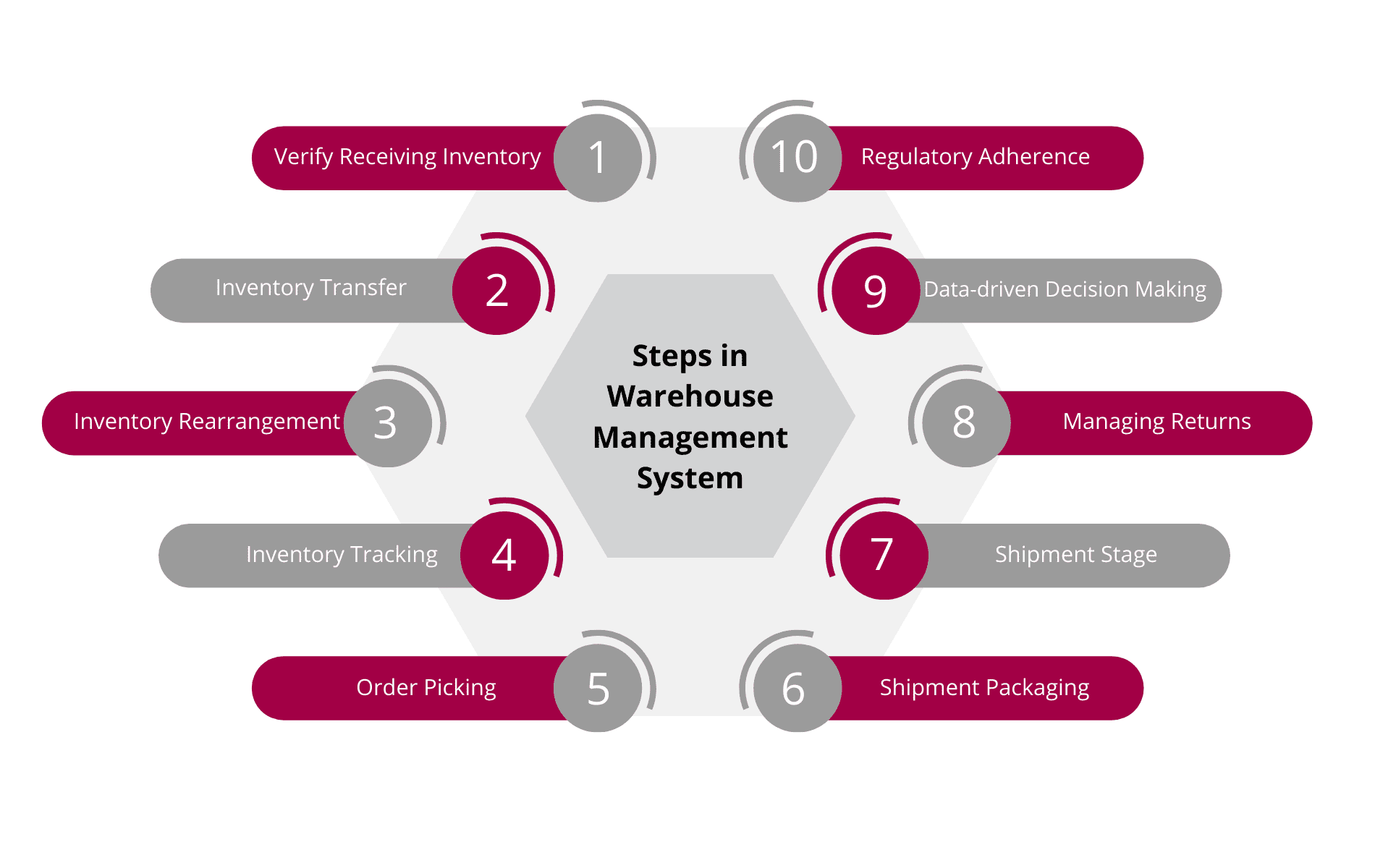

Steps in Warehouse Management System (WMS)

Warehouse Management System (WMS) is a comprehensive process that involves the following steps:

1. Verify Receiving Inventory

- Make sure that the inventory is received during the desired time frame

- Check the received inventory for accurate quantity

- Perform quality inspections to ensure the inventory meets the acceptable quality level

2. Inventory Transfer

- This stage involves transferring inventory from the dock to the relevant storage location

- It also involves making sure the inventory is easily accessible when required

- The exact location of the inventory is accordingly updated in the WMS System

3. Inventory Rearrangement

- The inventory is rearranged in such a manner to optimize the storage usage

- The company can implement either First-in-First-Out or Last-in-First-Out method

- The objective of this step is to enhance the inventory storage efficiency.

4. Inventory Tracking

- Classifying inventory into raw materials, ready-to-sell, and unfinished goods

- Keeping a close eye on the inventory threshold to prevent over-stocking & under-stocking

- Checking inventory catalog for potential errors & discrepancies

5. Order Picking

- This step involves the use of automated systems

- It involves bringing accuracy to order management using the automated order management system

- The system also prioritizes the client base based on their requirement type and urgency.

6. Shipment Packaging

- Preparing shipment for dispatch

- Making sure the right quantity of inventory is packaged

- Use of Safe Packaging to protect the package during transportation

7. Shipment Stage

- This phase involves coordinating with external stakeholders for smooth order shipment

- The employees make an entry into the WMS Software

- The customer receives a notification about the shipment details and tracking details

8. Managing Returns

- Managing the movement of damaged or faulty products from customers to the warehouse

- Assessing the condition of returned products

- Determining the future course of action for returned products

9. Data-driven Decision Making

- Generating inventory-specific and order-centric reports for higher-decision making

- Performing thorough data analysis to find trends, analysis, and anomalies

- The higher management takes appropriate decisions based on the submitted reports

10. Regulatory Adherence

- Keeping a close eye on the latest regulatory standards

- Drafting emergency protocols and training employees on safety standards

- Performing regular safety audits

Difference Between Warehouse Management System and Inventory Management System

Warehouse Management System and Inventory Management System are two highly inter-linked, yet distinct concepts. Here’s the fundamental difference between them:

Important Factors to Consider While Choosing the Best Warehouse Management System

1. Centralized View of Inventory

These days, it’s common for business entities to have separate units across the same country or different nations. As a business expands into multiple units, so does its inventory complexities. Tracking, handling, and facilitating inventories to different units can be a cumbersome task. Thanks to the Warehouse Management System, decision-makers can get a centralized view of inventory across different units, track inventory allocation, and optimize inventory levels.

2. Track Demand Variations

In today’s highly customer-centric business landscape, businesses have to regularly track the demand for their products & services, and ensure they’re up-to-date with the latest market trends. The Warehouse Management System provides customized dashboards and intelligently crafted reports to understand demand patterns, seasonal trends, and fluctuations. Accordingly, decision-makers can make strategic decisions to combat new challenges.

3. Implementation Support

Another factor that is often overlooked is the vendor’s support during the deployment phase. Consider purchasing a Warehouse Management System from a reputed vendor with a successful track record of several years in the market. Your vendor’s specialized implementation team will have the skills and training to ensure a smooth deployment without zero or minimal disruptions in your business operations. Sure, this might cost you a bit of money, but isn’t it better than suffering financial loss due to disruptions in business operations?

4. Cloud Support

Cloud has become an integral part of our lives, and so has business activities. A good WMS should support storing your data on the cloud so that your employees can access it regardless of where they are, and which device they use. Not just that, the cloud eliminates the hardware upgradation costs associated with the traditional on-site deployment, thus saving you from the hassle of managing a separate workforce & additional budget.

5. Third-party Integrations

Do you want to use your Warehouse Management System in addition to your existing legacy systems? If so, you will want to make sure that it supports wider integration with third-party systems, such as sales, billing, marketing, IoT, and procurement. Make sure that your WMS Software supports integration with other popular third-party legacy systems to ensure minimal business disruptions.

Future-Proof Your Business with Sage X3

Take control of your business with Sage X3 at the helm

Future Trends in the Warehouse Management System

1. Warehouse Automation

Warehouse Automation consolidates data from different sources and automates workflow and warehouse processes using barcode scanning, labeling, and shipment tracking. The increased reliance on automation reduces human errors and provides consistency & standardization throughout the different processes.

2. Internet of Things (IoT)

Internet of Things (IoT) technology builds a network of interconnected devices for real-time data transmission. The data is captured using IoT Sensors and made available to relevant teams directly on their smartphones, computers, and tablets. IoT enables a useful way to identify discrepancies in the warehouse management system, reduce costs, and accurately plan & forecast inventory levels.

3. Artificial Intelligence (AI)

In today’s era of Artificial Intelligence (AI), businesses can benefit tremendously from automation, accurate predictions, trend identification & analysis, and waste production to cost-efficiency. AI has brought transformative changes that ensure your business mitigates inventory-specific challenges and becomes agile to the latest market challenges.

4. Voice-picking Device

Recently, voice-picking devices are gaining popularity among businesses. Warehouse staff use them to pick up warehouse items by voice — whether immediately or at their scheduled time. This eliminates the need for paperwork and manual entry, which saves time, reduces labor work, and brings efficiency throughout the entire process.

5. Augmented Reality (AR)

Augmented Reality (AR) empowers businesses with smart glasses to capture the real environment and eliminate physical efforts in handling tasks. Similarly, Virtual Reality (VR) involves training lift operators and ensuring faster and smoother delivery of products on the predecided delivery routes. An effective use of both these technologies can speed up warehouse operations.

Optimize Your Warehouse Management Using Sage X3

Do you frequently experience inventory shortages & over-stocking problems? Is your business unable to cope with the growing demand for your products due to the slow & tedious order fulfillment process? If so, it’s time to invest in a warehouse management system. In today’s fast-paced and highly complex business environment, it serves as the central orchestrator for optimizing your warehouse activities & order fulfillment process.

Sage X3 is a high-end solution that completely revamps the traditional process of warehouse management and addresses a myriad of issues faced by modern-day businesses. Businesses can leverage their technological capabilities to use their warehouse storage more efficiently, better coordinate between different departments, minimize errors, and fulfill customer orders quickly & efficiently

Top Industries Leveraging ERP Software

Food & Beverage

Alcohol

Pharmaceuticals

Advertising

IT Services

Furniture

Manufacturing

Auto Ancillary

Pharma Trading

Packaging

Medical Device

Chemical

Plastic

Brewery

Logistics

Automotive

Frequently Asked Questions

What is the Definition of Warehouse Management System (WMS)?

Warehouse Management System meaning is a platform that helps businesses manage their everyday warehouse operations, from tracking inventory to streamlining order picking & shipment procedures. It plays a crucial role in the order fulfillment process and enables decision-makers to respond swiftly to sudden market trends & changes.

Which Industries Commonly Use the Warehouse Management Software?

Warehouse Management Software is commonly used across different industries from manufacturing, furniture, pharmaceutical, auto ancillary, auto components manufacturers, chemical , aluminum, food, furniture manufacturing, filter manufacturing, plastic and electric vehicle manufacturing industry. However, as the size and requirements of each of these industries vary, your WMS Software is tailored to meet those industry-specific requirements. It contains industry-specific functionalities to streamline business functions, reduce costs, and improve agility.

How Does the WMS Software Enhance Inventory Accuracy?

For any business – whether small or large, it’s important to have complete and accurate knowledge about the actual inventory counts. Extended Warehouse Management reduces discrepancies that may occur due to human errors, stock misplacement, mistaking one stock for another, and countless other reasons. It also eliminates the need for annual reconciliation, a process that involves temporarily shutting down the core business activities for inventory re-counting.

How Does the WMS System Speed Up the Order Fulfilment?

Order fulfillment is an essential procedure that requires collaboration with multiple business departments and partners. Warehouse Management Software provides all-encompassing information about the entire process, bringing accuracy to the order-picking and shipping process, and reducing repetitive tasks.

How Much Does an Extended Warehouse Management Cost?

The actual cost of Warehouse Management Software may vary on different factors. It may include the licensing fees (either to be paid upfront in the case of an On-premise solution, or no upfront fees in the case of a cloud solution), per-user cost, implementation fees, hardware upgradation cost, and any other charges. A cloud-based WMS system is typically considered cost-effective compared to an on-premise solution.

Schedule Product Tour

"*" indicates required fields